Door panel spraying device

A technology of spraying device and door panel, which is applied in spraying device, painting room, etc., can solve the problems of low efficiency and long pause time, and achieve the effect of reducing impact, improving painting efficiency and reducing painting downtime.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

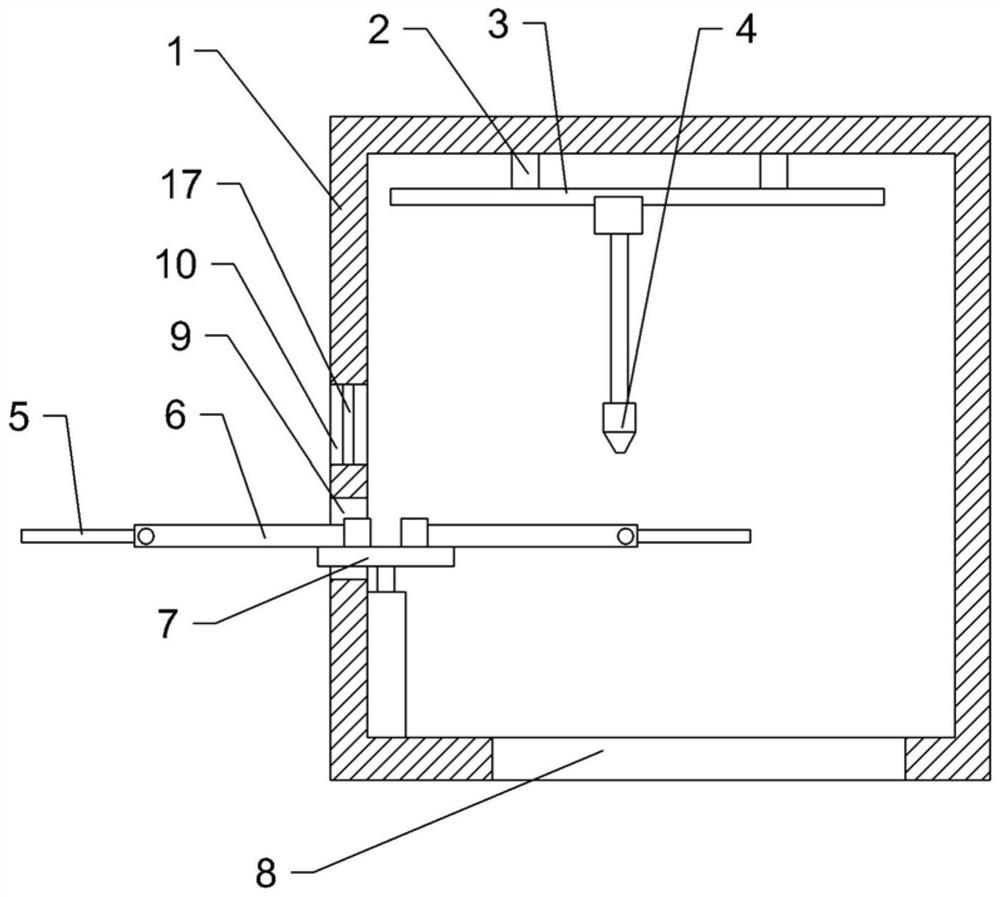

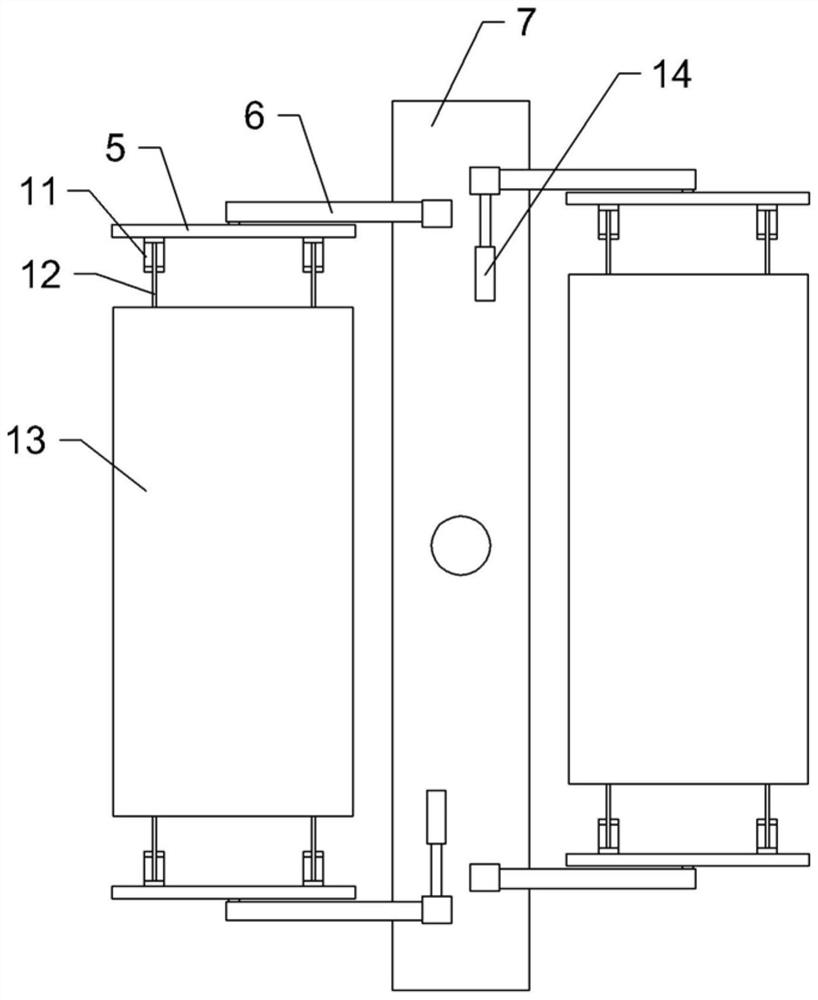

[0021] Embodiment one: as attached figure 1 and figure 2 Shown: a door panel spraying device, including a cuboid box 1, the side of the box 1 is provided with a pick-and-place opening 9, and an observation window 10 is opened on the upper side of the pick-and-release opening 9, and a transparent The observation plate 17, the bottom of the box body 1 has an exhaust port 8; the top inside the box body 1 is connected with the first guide rail 2 by bolts, and the first guide rail 2 is parallel to the length direction of the box body 1; on the first guide rail 2 The first rack is bolt-connected along the length direction; the first slider is slidably connected to the first guide rail 2, the first slider is connected with the first servo motor by bolts, and the key on the first servo motor is connected with the first tooth rack. The first gear meshed with the bar; the second guide rail 3 is slidably connected to the first slider along the width direction parallel to the box body 1...

Embodiment 2

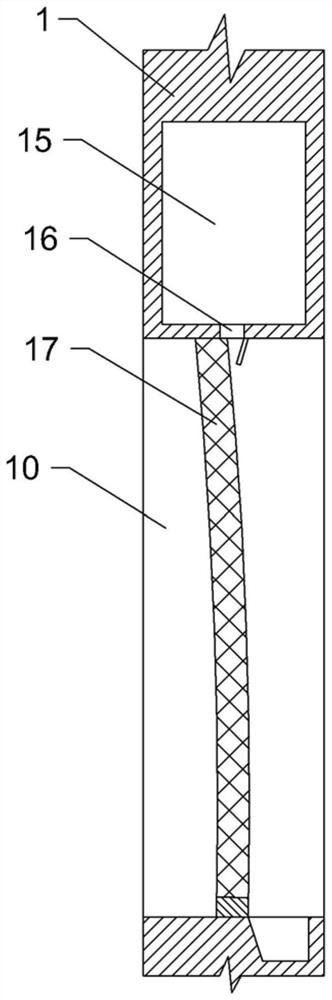

[0025] Embodiment 2: The difference from Embodiment 1 is only that a water curtain mechanism is provided on the side opposite to the pick-and-place opening 9 inside the box body 1, and the water curtain mechanism includes a water spray pipe connected to the top of the box body 1 and a water curtain mechanism. The sump located at the bottom of the box body 1, the water spray pipe is connected to the water pump, and the water pump sprays water from the water spray pipe and flows into the sump to form a water curtain; image 3As shown, on the casing 1, a water storage chamber 15 is provided on the upper side of the observation window 10, and the bottom of the water storage chamber 15 is provided with a drainage hole 16 communicating with the observation window 10; Through the flexible connection of the rubber block, the upper end of the observation plate 17 is integrally formed with a stopper, and the stopper slides and covers the lower side of the drain hole 16, and the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com