Watering machine for mine reclamation

A technology for watering machines and mines, applied in watering devices, applications, gardening, etc., can solve problems such as increasing labor costs and low work efficiency, achieve uniform moving speed, ensure uniform watering, and improve practicability and flexibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

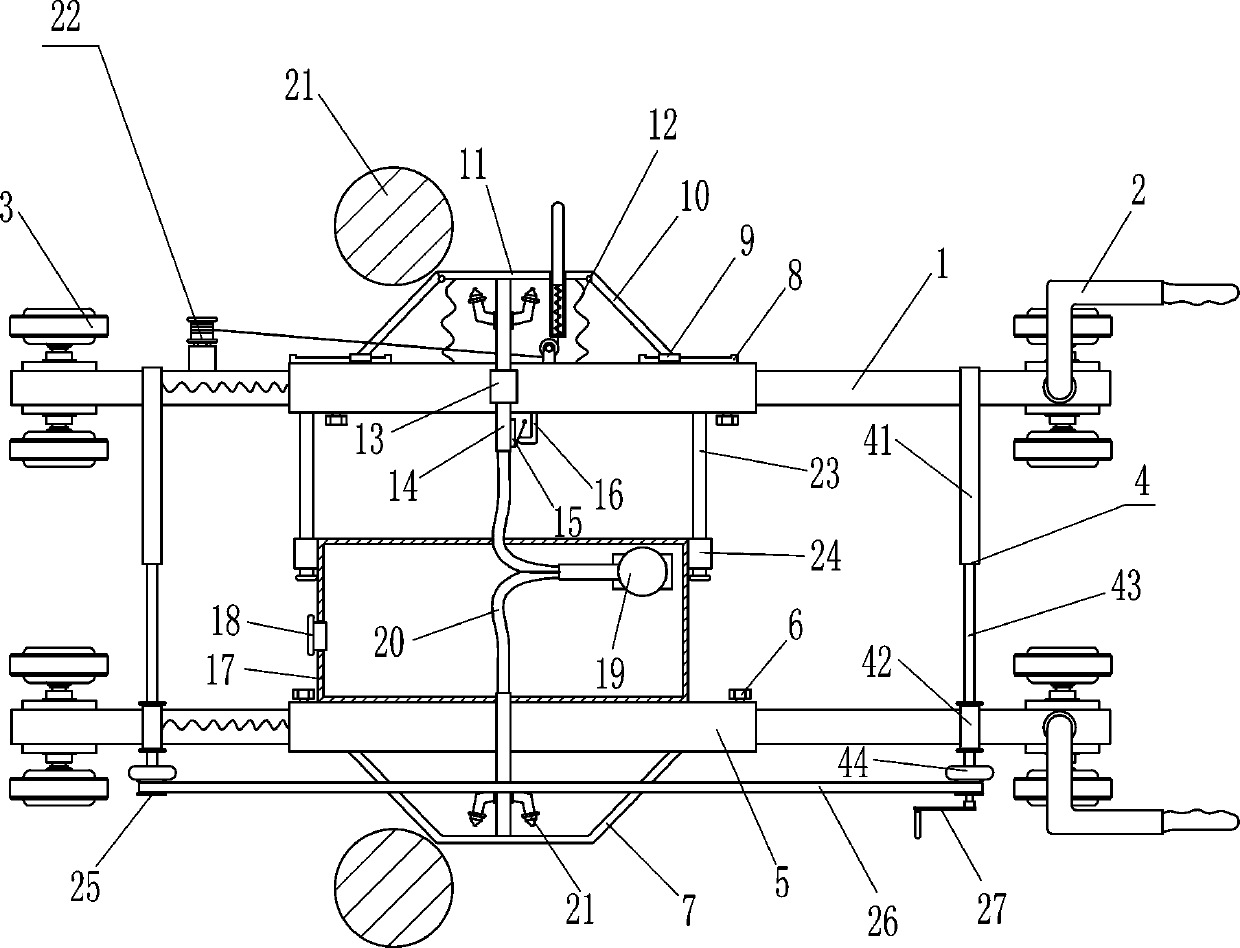

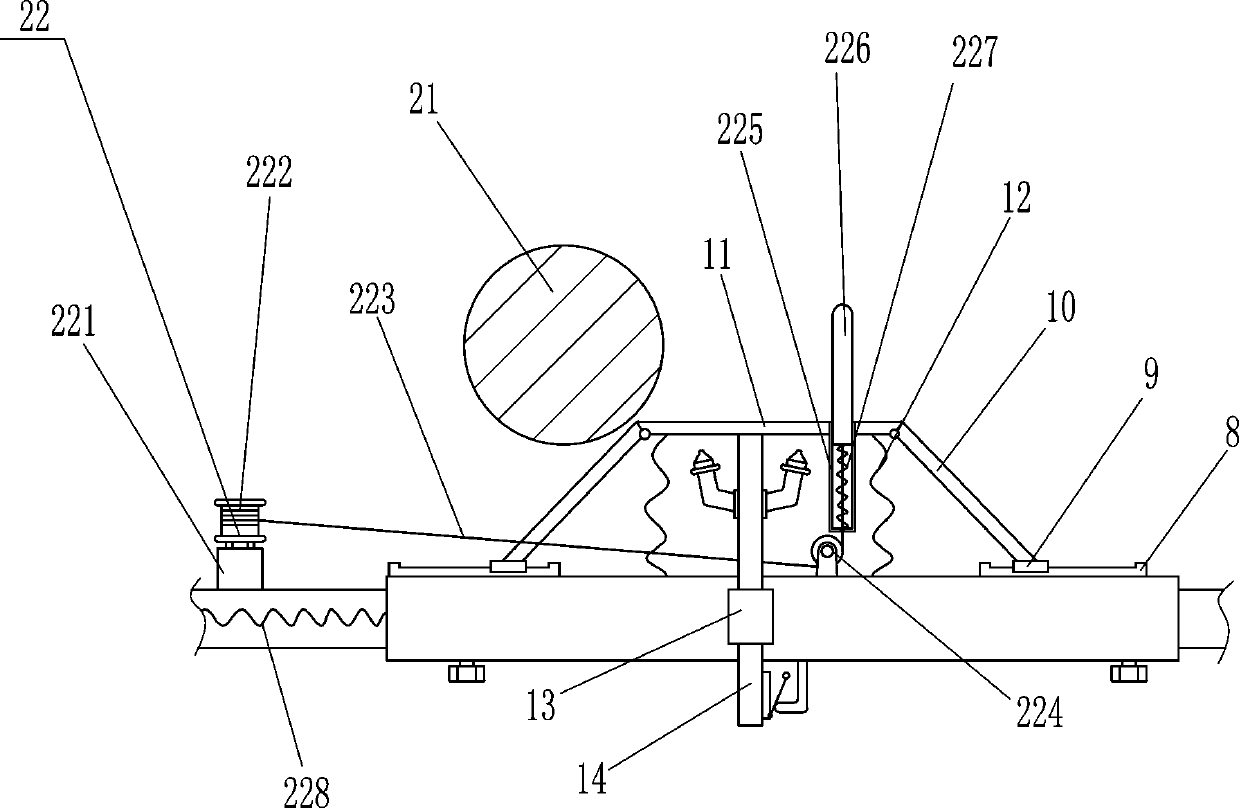

[0020] A watering machine for mine reclamation, such as Figure 1-2 As shown, it includes a mounting frame 1, a handle 2, an electric wheel 3, a distance adjustment mechanism 4, a sliding plate 5, a fastening bolt 6, a V-shaped bracket 7, a slide rail 8, a slider 9, a connecting rod 10, and a connecting rod 11 , the first spring 12, the sliding sleeve 13, the hard outlet pipe 14, the contact switch 15, the contact rod 16, the water tank 17, the cover 18, the water pump 19, the soft outlet pipe 20 and the nozzle 21, and the two installation frames 1 are symmetrically arranged front and back, and the installation A handle 2 is connected to the top of the right side of the frame 1, electric wheels 3 are installed on the left and right sides of the bottom of the mounting frame 1, a distance adjustment mechanism 4 is provided between the front and rear mounting frames 1, and a sliding plate is connected to the middle of the mounting frame 1 in a sliding manner 5. There are fastenin...

Embodiment 2

[0022] A watering machine for mine reclamation, such as Figure 1-2 As shown, it includes a mounting frame 1, a handle 2, an electric wheel 3, a distance adjustment mechanism 4, a sliding plate 5, a fastening bolt 6, a V-shaped bracket 7, a slide rail 8, a slider 9, a connecting rod 10, and a connecting rod 11 , the first spring 12, the sliding sleeve 13, the hard outlet pipe 14, the contact switch 15, the contact rod 16, the water tank 17, the cover 18, the water pump 19, the soft outlet pipe 20 and the nozzle 21, and the two installation frames 1 are symmetrically arranged front and back, and the installation A handle 2 is connected to the top of the right side of the frame 1, electric wheels 3 are installed on the left and right sides of the bottom of the mounting frame 1, a distance adjustment mechanism 4 is provided between the front and rear mounting frames 1, and a sliding plate is connected to the middle of the mounting frame 1 in a sliding manner 5. There are fastenin...

Embodiment 3

[0025] A watering machine for mine reclamation, such as Figure 1-2As shown, it includes a mounting frame 1, a handle 2, an electric wheel 3, a distance adjustment mechanism 4, a sliding plate 5, a fastening bolt 6, a V-shaped bracket 7, a slide rail 8, a slider 9, a connecting rod 10, and a connecting rod 11 , the first spring 12, the sliding sleeve 13, the hard outlet pipe 14, the contact switch 15, the contact rod 16, the water tank 17, the cover 18, the water pump 19, the soft outlet pipe 20 and the nozzle 21, and the two installation frames 1 are symmetrically arranged front and back, and the installation A handle 2 is connected to the top of the right side of the frame 1, electric wheels 3 are installed on the left and right sides of the bottom of the mounting frame 1, a distance adjustment mechanism 4 is provided between the front and rear mounting frames 1, and a sliding plate is connected to the middle of the mounting frame 1 in a sliding manner 5. There are fastening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com