A printing machine doctor blade system with leveling function

A technology of leveling function and squeegee, applied in printing presses, general parts of printing machinery, printing and other directions, can solve the problems of uneven distribution of ink on printing plate cylinders, inconsistent horizontal and left heights, uneven distribution of ink marks, etc. The effect of scraping the plate cylinder is uniform, uniform in pressure and uniform in force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

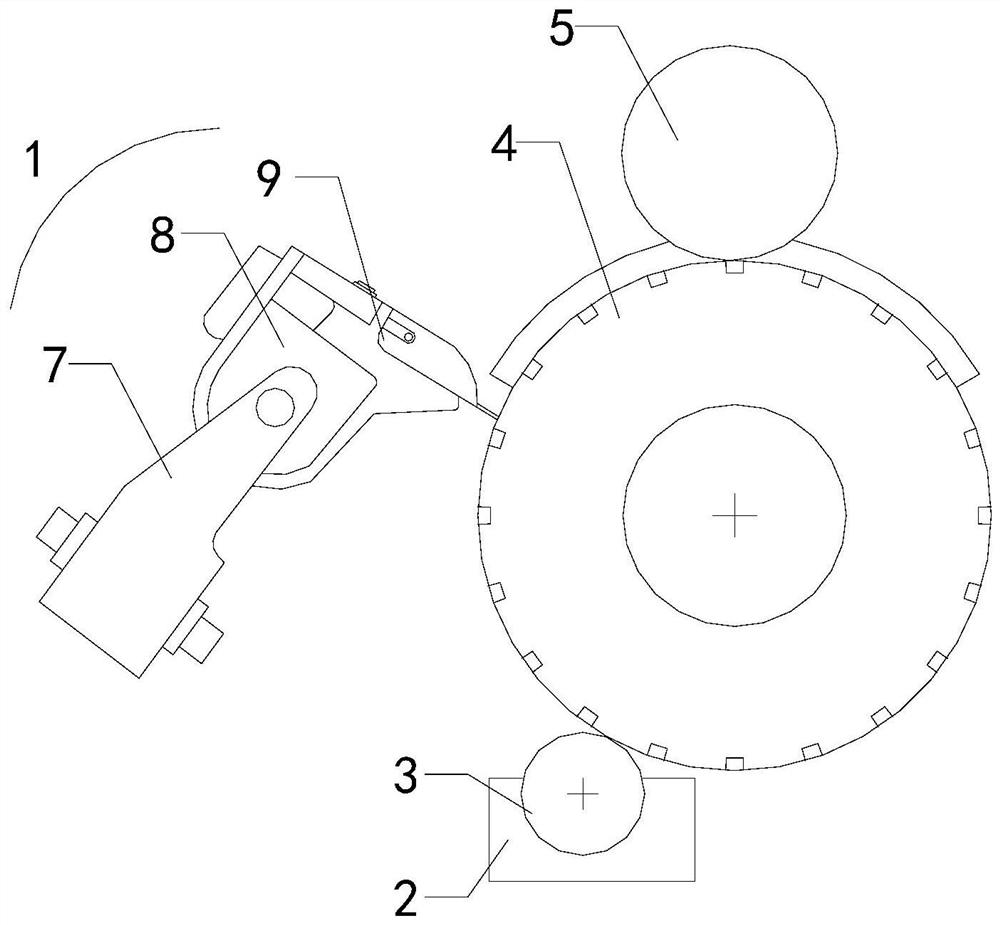

[0024]SeeFigure 1-Figure 6, The present invention provides a printing press doctor blade system with leveling function, the structure includes a doctor blade structure 1, an ink tank 2, an ink transfer roller 3, a plate cylinder 4, an impression cylinder 5, the ink tank 2 is provided with an ink transfer roller 3, the ink transfer roller 3 is located obliquely below the plate cylinder 4, the plate cylinder 4 and the ink transfer roller 3 are movably attached, and a scraper is installed on one side of the ink transfer roller 3 In the ink knife structure 1, an impression cylinder 5 is arranged in the middle of the opposite top ends of the printing plate cylinder 4 and the ink tank 2, and the impression cylinder 5 and the printing plate cylinder 4 are in close contact.

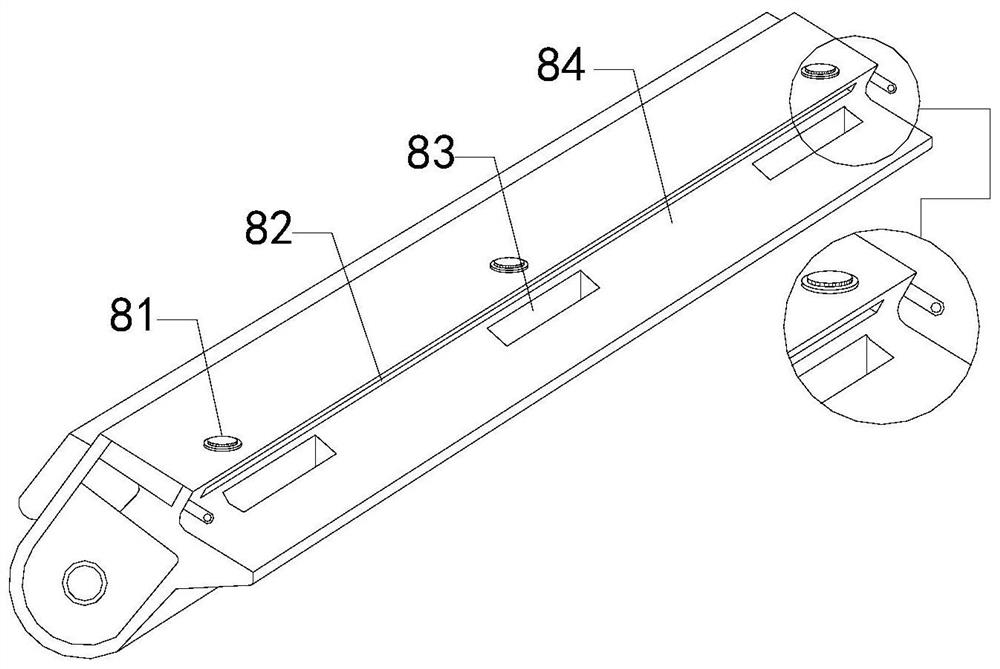

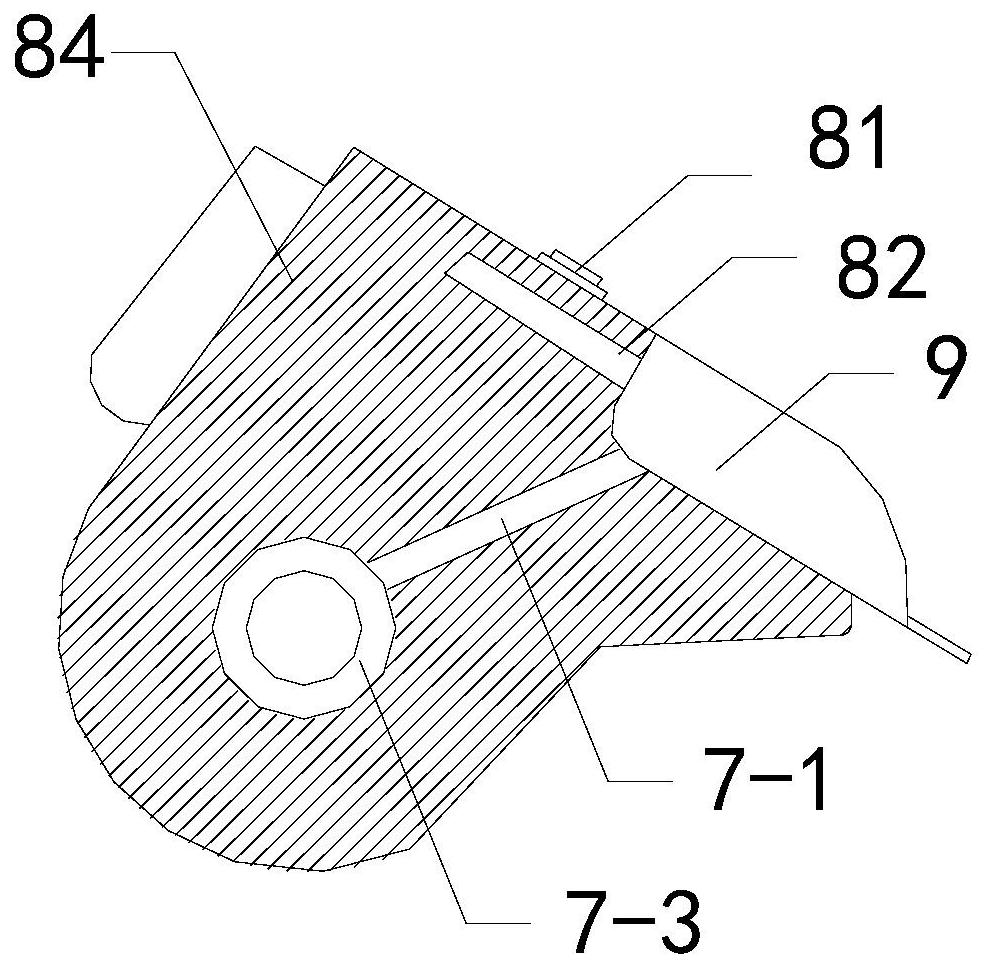

[0025]The squeegee structure 1 is composed of a suction and pressure structure 7, a bottom plate 8, and a squeegee 9. A suction and pressure structure 7 is arranged on the side of the bottom plate 8, and a squeegee 9 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com