Garment pattern making and collar matching method using angle principle

An angle and clothing technology, applied in the field of clothing plate making and matching based on the principle of angle, can solve the problems of inaccurate matching and low work efficiency, and achieve the effect of improving the matching level, teaching quality and employment rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

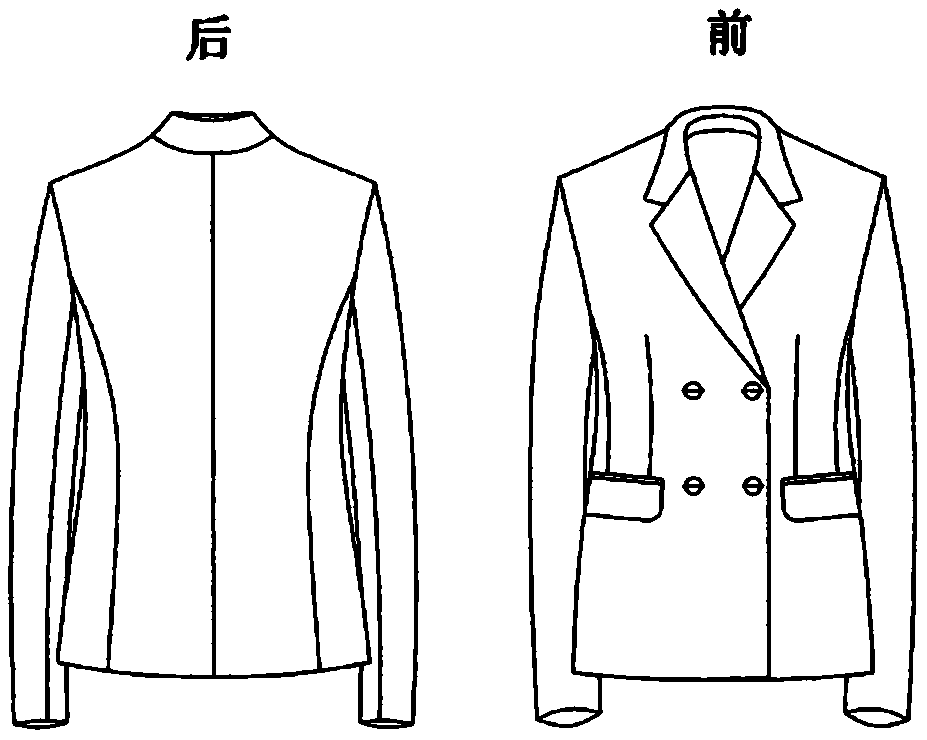

[0032]The invention relates to a method of matching collars for clothing plate making based on the principle of angles. Description of the collars: the collar is (women's clothing), size M, and the collar is a straight lapel of a suit collar.

[0033] Collar opening width: In spring and autumn, the suit should be on the basic collar, and the opening width of 1.6-1.8cm is suitable. The collar opening width of winter coats and coats should be larger, generally 2-2.5cm.

[0034] The normal ratio of the face collar to the bottom collar, the face collar is 1.5-2cm larger than the bottom collar. For the unconventional large collar with the face collar larger than the bottom collar by more than 2cm, another method should be used for its matching method. The present invention is explained with the matching collar of the suit collar of conventional ratio;

[0035] Let the face collar be 4.5cm and the bottom collar be 3cm.

[0036] Distribution formula:

[0037] Such as figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com