Mounting method and mounting structure of roller blind

A technology of installation structure and installation method, which is applied in the direction of building components, building structures, door/window protection devices, etc., can solve the problems of not affecting the waterproof effect of the building's external wall insulation layer and waterproof layer, so as to save product protection and maintenance costs , optimize the installation method, and improve the effect of the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

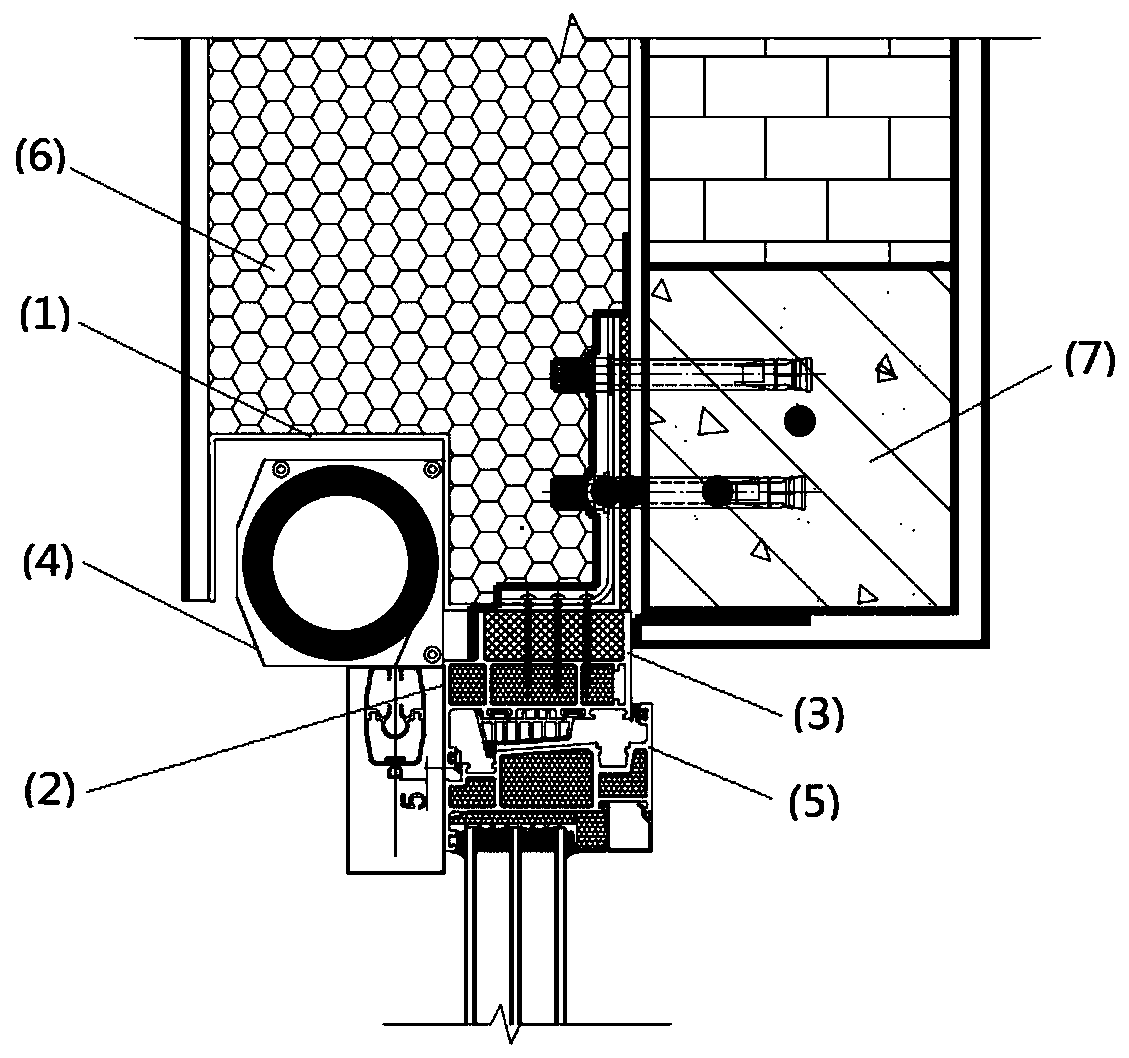

[0026] Such as figure 1 As shown, the present invention provides a rolling blind installation structure, which mainly includes a rolling blind outer box 1, a rolling blind system 2 with only guide rails fixed, a window frame 3, a rolling blind inner box 4, a window sash 5, an insulation layer 6, Wall 7. One side of the rolling shutter outer box 1 and the upper end of the window frame 3 are fixed together on the wall 7 above the reserved window through angle steel, and the inner side of the rolling shutter guide rail of the rolling shutter system 2 is installed on the left and right sides of the window frame 3. The curtain inner box 4 is fixedly connected with its roller blind guide rail, and is not directly connected with the upper side of the window frame 3 . The insulation layer 6 covers the outer side of the roller blind outer box 1, and the outer side of the insulation layer 6 is provided with a decorative layer.

[0027] The roller blind outer box 1 has the function of ...

Embodiment 2

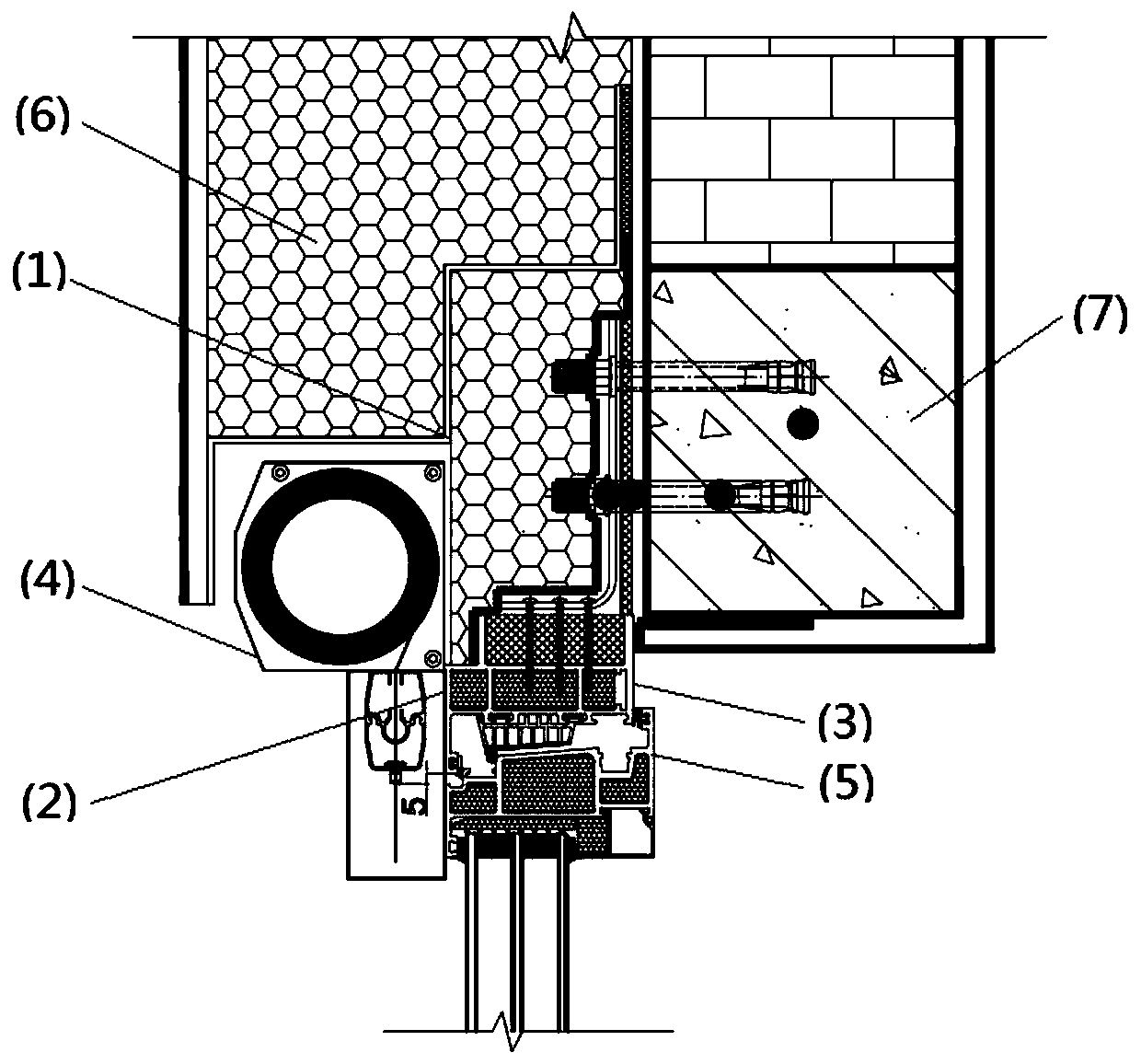

[0035] Such as figure 2 As shown, the present invention provides a rolling blind installation structure, which mainly includes a rolling blind outer box 1, a rolling blind system 2 with only guide rails fixed, a window frame 3, a rolling blind inner box 4, a window sash 5, an insulation layer 6, Wall 7. Roller shutter outer box 1 is fixed separately on the wall 7 above the reserved window, and is not connected with window frame 3. Window frame 3 is also fixed on wall 7 through angle steel. The gap between roller shutter outer box 1 and wall 7 Through foam filling, the inner side of the roller shutter guide rail of the roller shutter system 2 is installed on the left and right sides of the window frame 3 , and the roller shutter inner box 4 is fixedly connected to the roller shutter guide rail, and is not directly connected to the upper side of the window frame 3 . The insulation layer 6 covers the outer side of the roller blind outer box 1, and the outer side of the insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com