Header device and giant rice combine-harvester

A technology for harvesters and headers, which is applied to harvesters, cutters, agricultural machinery and implements, etc., and can solve problems such as poor adaptability, stalk winding around the reel, and unsmooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

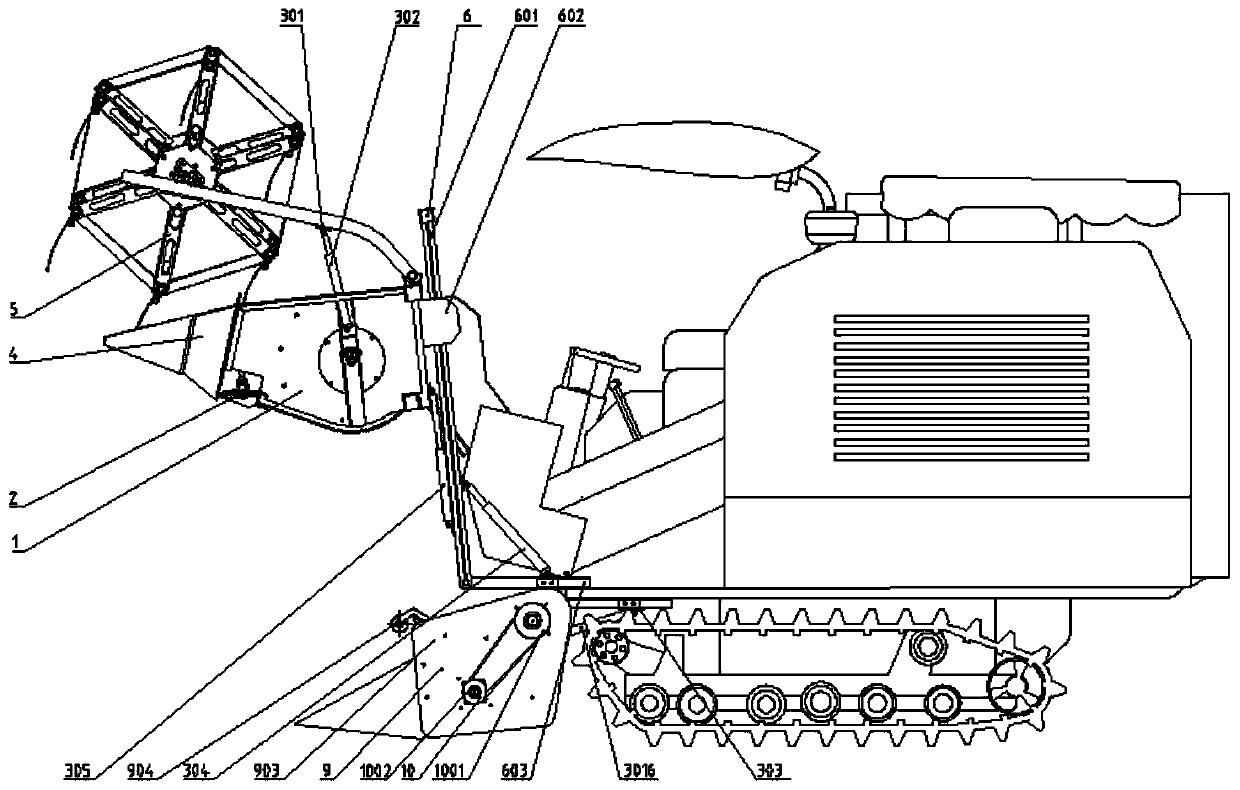

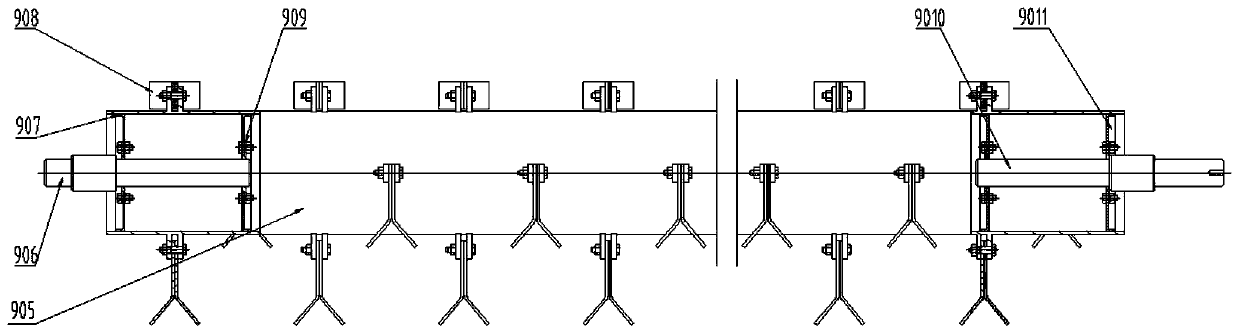

[0029] Such as figure 1 Shown is a preferred embodiment of the header device of the present invention, the header mechanism and the straw returning mechanism 9; the header mechanism and the straw returning mechanism 9 are used to be installed on the front end of the harvester, and the cutting The platform mechanism is positioned at the top of the straw returning mechanism 9 . The header mechanism and the straw returning mechanism 9 arranged up and down form a double-layer header device. The harvesting and feeding of rice ears are completed through the upper layer header mechanism, and the lower layer adopts the front straw returning mechanism to remove the stalks of the harvested rice ears. Carry out crushing and returning to the field, complete the work of harvesting up and down, especially suitable for the harvest of "giant rice", which better adapts to the characteristics of super high stems of "giant rice", and solves the problem of harvesting "giant rice" with ordinary cu...

Embodiment 2

[0042] A giant rice combine harvester, including the header device described in Embodiment 1, therefore includes the beneficial effects of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com