Steam Injection Method for Heavy Oil Thermal Recovery Wells

A heavy oil thermal recovery and steam injection technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as poor production effect and unbalanced production degree, and solve the problem of poor production effect, Strong compression resistance and low gas solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

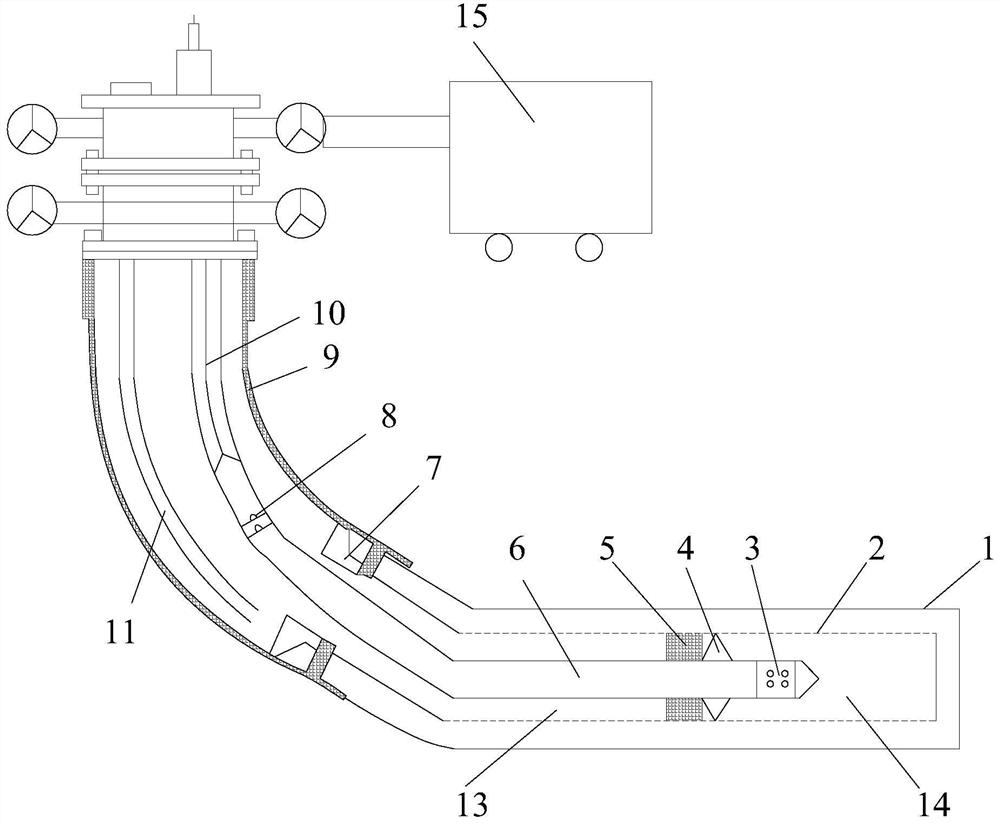

[0022] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0023] like figure 1 As shown, the embodiment of the present invention provides a kind of steam injection method of heavy oil thermal recovery well, and heavy oil thermal recovery well comprises vertical well section and the horizontal well section connected with vertical well section, and steam injection method comprises:

[0024] Step S10: judging the producing degree of each part of the horizontal well section;

[0025] Step S20: Injecting steam into the horizontal well section;

[0026] Step S30: continue to inject steam into the part with low production degree of the horizontal well section, and inject inert gas into the part with high production degree of the horizontal well section.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com