Integrated water treatment system for multi-dimensional spraying haze removal equipment

A water treatment system, multi-scale technology, applied in the direction of water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc., can solve the problem of the independent system without disassembly and the inconvenience of water treatment system piping and debugging And maintenance and other issues to achieve the effect of improving production efficiency, facilitating mass production of equipment and post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

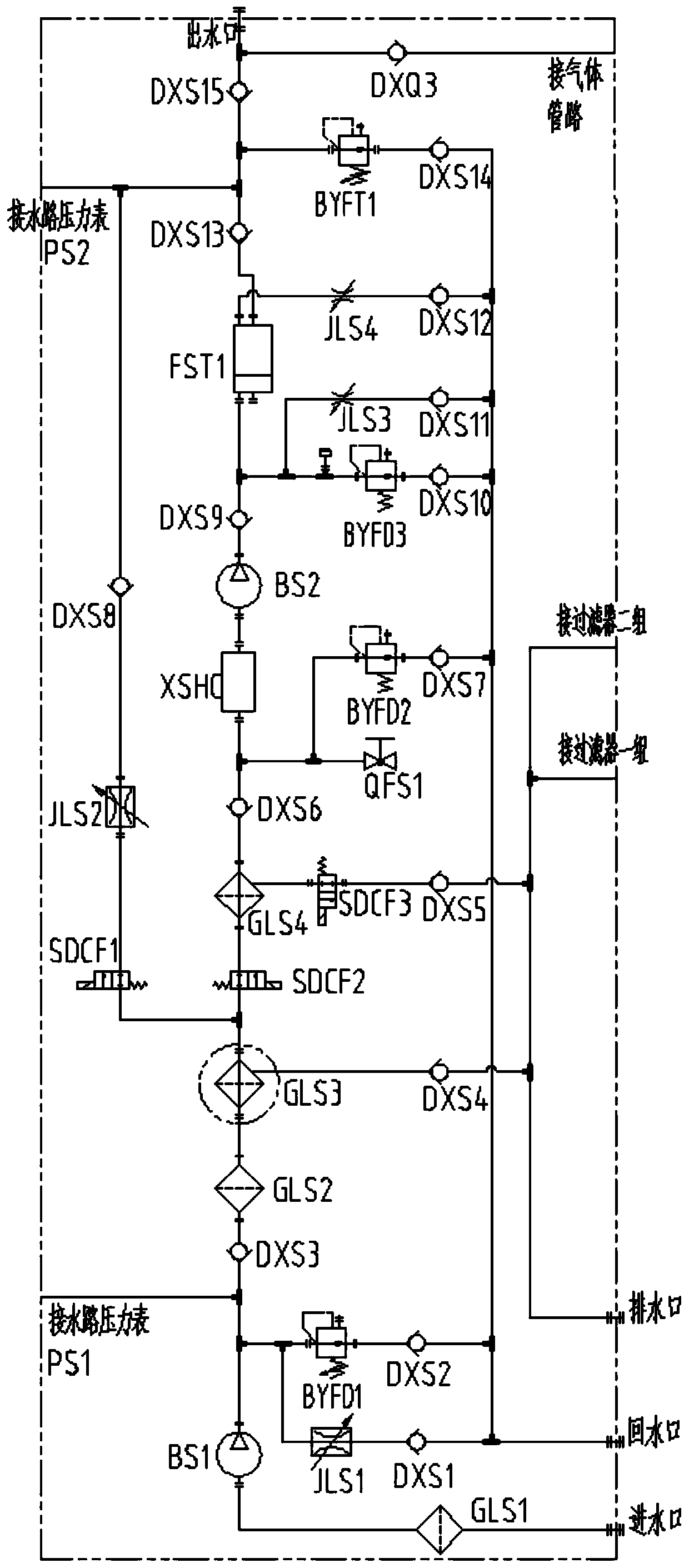

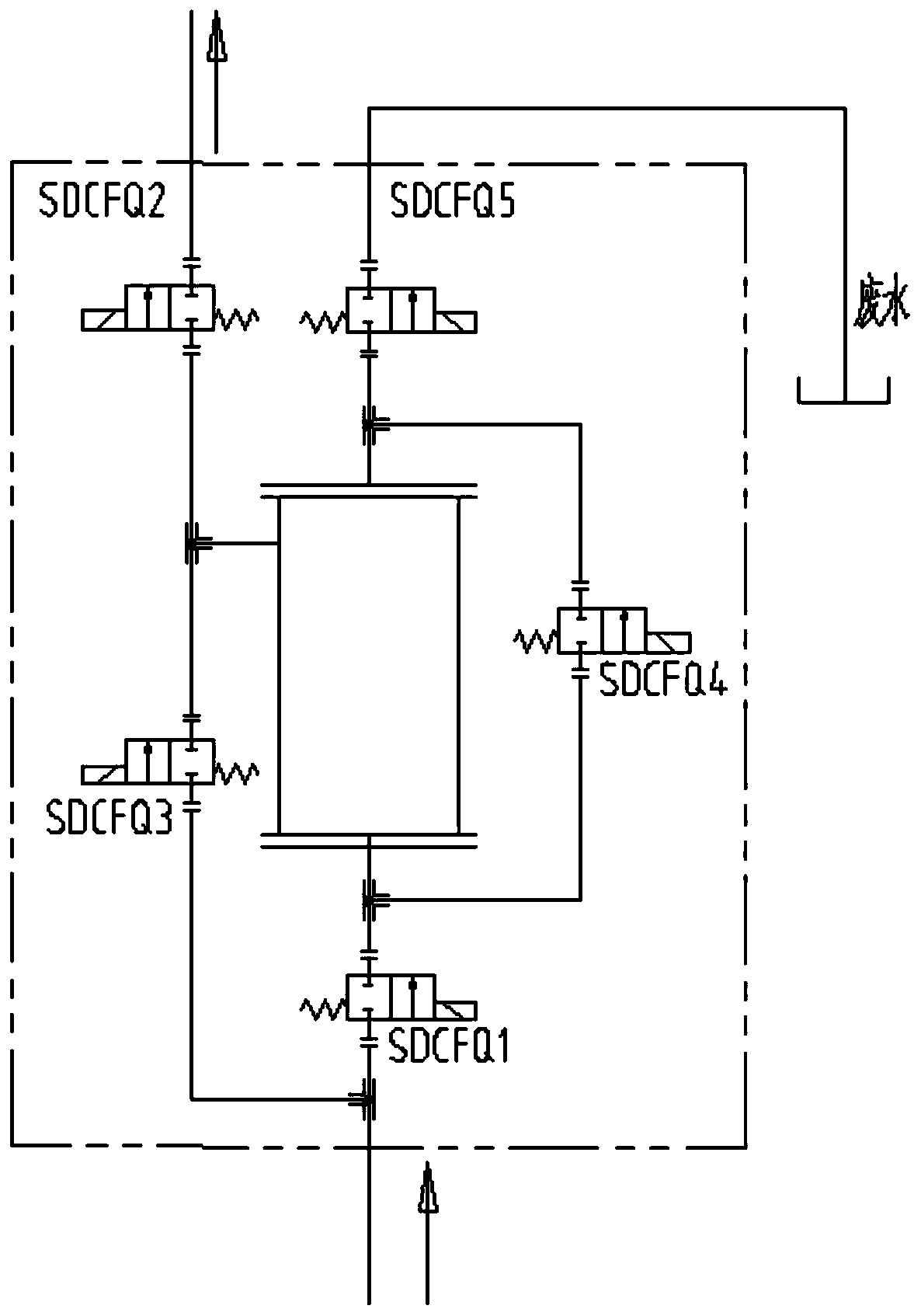

[0028] This embodiment provides an integrated water treatment system for multi-scale spray haze removal equipment;

[0029] Such as Figure 1-Figure 7 As shown, the integrated water treatment system for multi-scale spray haze removal equipment in this embodiment includes a waterway system and a bracket assembly 1, and the waterway system is arranged on the bracket assembly 1 for controlling the The water is purified and pressurized, and the support assembly 1 is detachably connected to the bottom of the host cabinet.

[0030] The present invention is provided with a waterway system and a bracket assembly, the waterway system is arranged on the bracket assembly, and is used to purify and pressurize the water entering the host cabinet, and the bracket assembly is detachably connected to the bottom of the host cabinet, which can It is convenient to take it out of the host cabinet as a whole for related piping, debugging and maintenance. At the same time, relevant pipeline interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com