Full cross-section tunneling machine tool changing robot testbed and tool changing simulation method

A technology of tunnel boring machine and robot, which is applied in tunnels, manipulators, earthwork drilling and mining, etc. It can solve the problem of poor simulation of tool changing process of tool changing robot, and achieve the effect of reducing research and development costs and accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

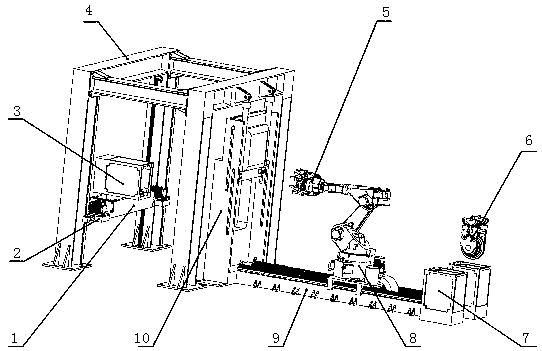

[0034] Example 1, such as figure 1 As shown, a full-section tunnel boring machine tool-changing robot test bench includes a beam frame 4 and a tool storage box 7 for storing tools 6. Lifting devices 2 and warehouse doors are respectively provided on the opposite sides of the beam frame 4. Mechanism 10, the lifting device 2 is provided with a tool horizontal adjustment device 1, and the tool horizontal adjustment device 1 is equipped with a knife box 3. Through the tool horizontal adjustment device and the lifting device, it is used to adjust the different postures of the knife box 3, simulating the most realistic Tool box state, that is, the tools are distributed in the circumferential direction on the tool head, and different tools have different polar diameters and polar angles. The tool box tool replacement in different states is simulated by the tool horizontal adjustment device and the lifting device. A moving guide rail 9 is provided between the tool storage box 7 and th...

Embodiment 2

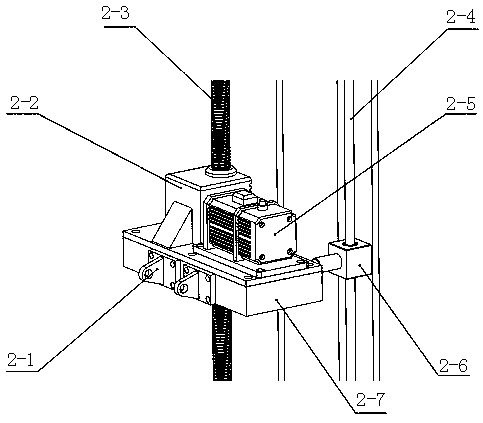

[0037] Example 2, such as image 3 and 12 As shown, a full-section tunnel boring machine tool changing robot test bench, the lifting device 2 has two sets and is symmetrically arranged on both sides of the tool horizontal adjustment device 1, and each set of lifting device includes a vertically arranged on the beam frame 4 The lifting lead screw 2-3 on the top of the lifting screw 2-3 is threadedly connected with a lifting base 2-7, and the lifting base 2-7 is hinged with the hinge 1-3 on the traversing base through the hinged connector 2-1. The lifting base 2-7 is provided with a worm and gear lifting mechanism 2-2, and the worm and gear lifting mechanism 2-2 cooperates with the lifting screw 2-3, and the worm and gear lifting mechanism 2-2 is arranged on the lifting base 2-7. The second servo motor 2-5 is connected. That is, under the action of the second servo motor, the worm gear lifting mechanism is driven to move up and down along the lifting screw 2-3, so as to realiz...

Embodiment 3

[0040] Example 3, such as Figure 5 As shown, a full-section tunnel boring machine tool changing robot test bench, the door mechanism 10 includes a door frame 10-5, the door frame 10-5 is fixedly connected with the beam frame 4, and the door frame 10-5 There is a tool change channel 10-4 on the main viewing surface, and a chute 10-6 is provided on both sides of the door frame 10-5, and a sliding door 10-3 is provided in the chute 10-6, and a door 10-3 is provided. -3 cooperates with the tool change channel 10-4; the beam frame 4 is hinged with a hydraulic telescopic cylinder 10-1, and the telescopic end of the hydraulic telescopic cylinder 10-1 is hinged with the warehouse door 10-3. Under the action of the hydraulic telescopic cylinder, the door moves up and down along the chute to realize the opening and closing of the tool changing channel. The opening size of the tool change channel 10-4 simulates the space constraints of the real full-section tunnel boring machine, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com