Detection device for mold with detonator shell

A detection device and a casing technology are applied in the field of detonator casing moulding detection devices to achieve the effects of improving detection efficiency, simple structure and high detection accuracy.

Pending Publication Date: 2019-12-31

GUIZHOU PANJIANG CIVIL EXPLOSIVE +1

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to solve the above technical problems, the present invention provides a detonator shell mold loading detection device, which can detect problems in time by replacing manual detection with machines, and at the same time speed up the detection rate, improve the production efficiency of enterprises, and reduce the cost of enterprises

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

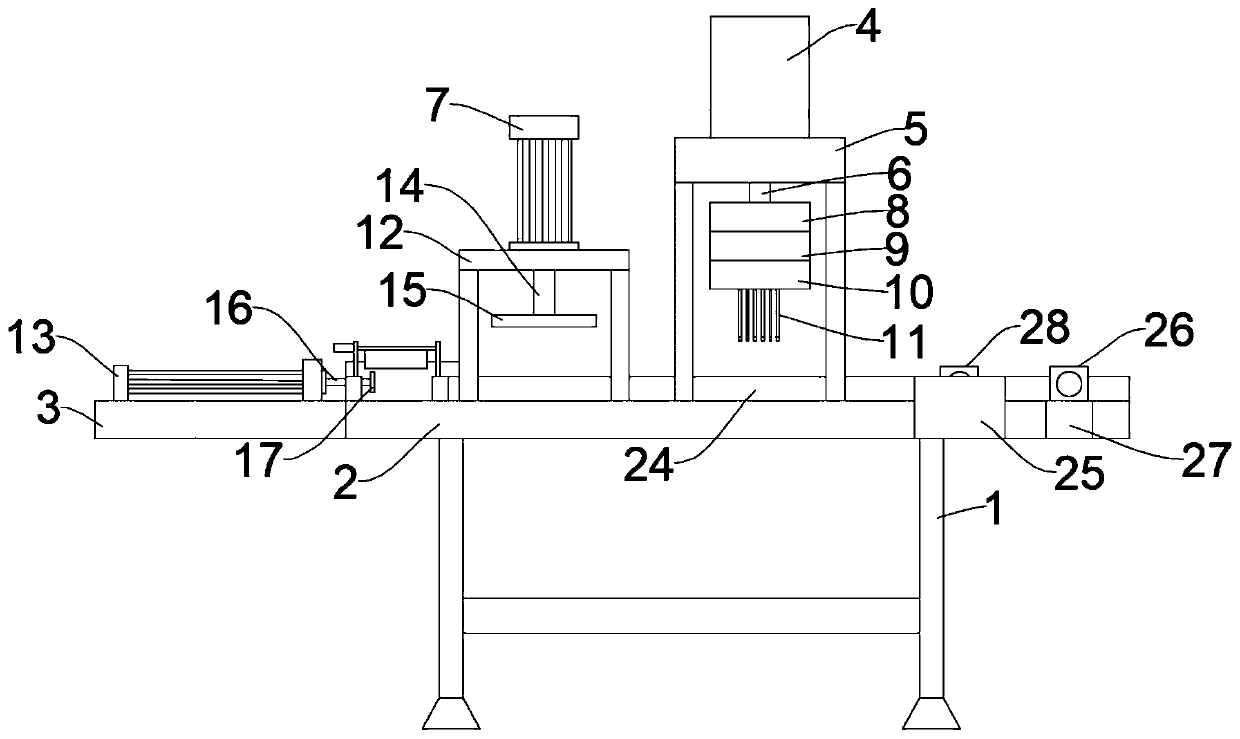

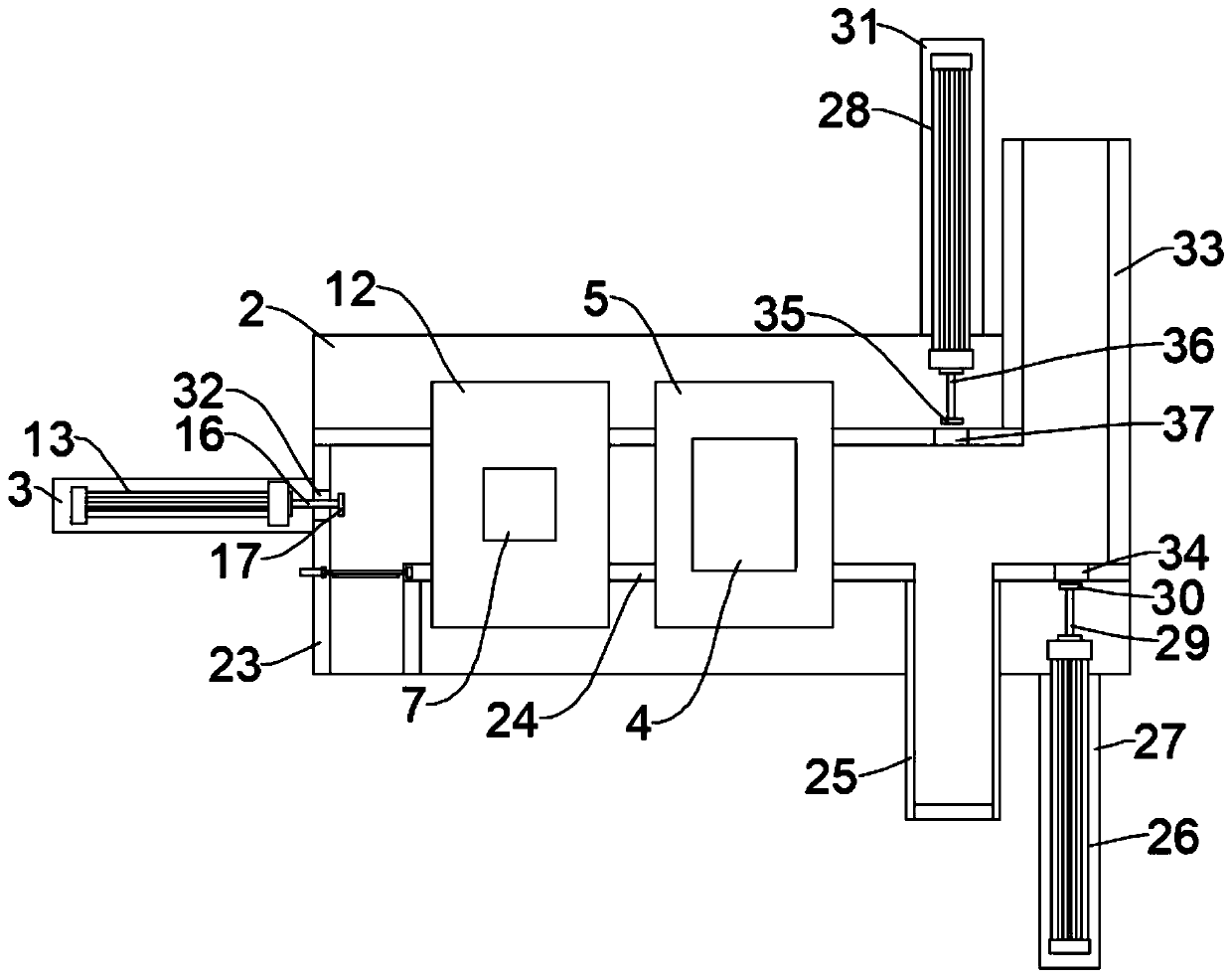

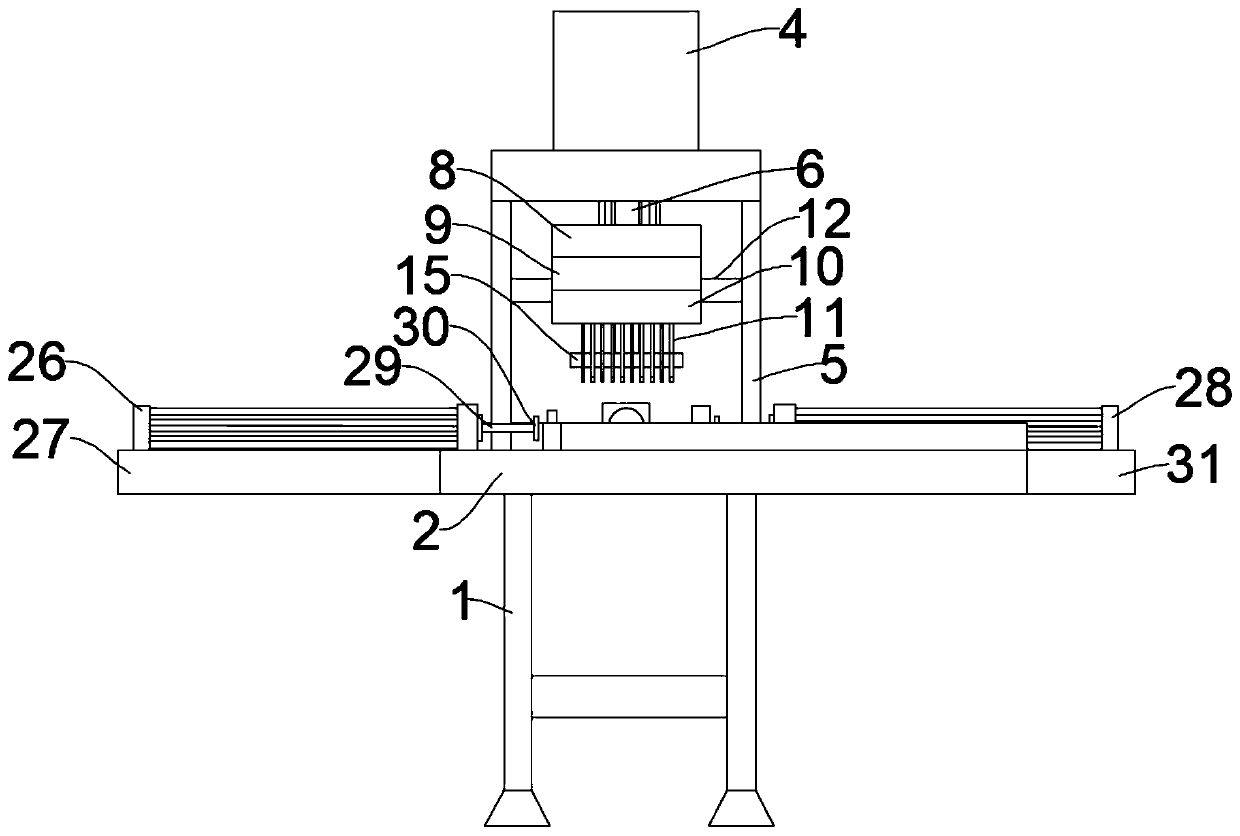

[0036] Such as Figure 1-Figure 4As shown, the present embodiment provides a detonator casing molding inspection device, which includes a horizontally arranged inspection platform 2, an inspection frame 5, an inspection channel and a plurality of manipulators for pushing the mold 38 to move in the inspection channel.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a detection device for a mold with a detonator shell, and belongs to the field of civil explosive detonator production. The detection device comprises a detection platform which is arranged horizontally, a detection frame body, a detection channel and a plurality of mechanical arms which are used to push the mold to move in the detection channel, wherein the detection frame body is fixedly arranged on the upper surface of the detection platform, the detection frame body is internally provided with a plurality of vertically arranged detection rods, the bottom ends of the detection rods are provided with sensors, a first air cylinder and a first push rod which is arranged vertically are arranged on the detection frame body, the first push rod is connected with the first cylinder in a driving mode, the bottom of the first push rod is fixedly connected with a fixing device for fixing the detection rods, and the top ends of the plurality of detection rods are fixedly connected with the fixing device; and the detection channel extends to the outside of the detection platform after penetrating through the detection frame body. The detection device for the mold with the detonator shell has the beneficial effect that the automatic detection is carried out through machine instead of manual work, at the same time, the detection speed is accelerated, the productionefficiency of an enterprise is improved, and the cost of the enterprise is reduced.

Description

technical field [0001] The invention belongs to the field of production of civil explosive detonators, and in particular relates to a mold-loading detection device for a detonator shell. Background technique [0002] The detonator is the main detonating material in a blasting project. Its function is to generate detonating energy to detonate various explosives, detonating cords and detonating tubes. During the production process of the detonator, it is necessary to put the detonator shell into a specific mold so that the opening of the detonator shell faces up and maintain a vertical state, then fill the explosive into the detonator shell, and then install the reinforced cap or extension body to assemble the finished detonator. [0003] After the detonator shell is loaded into the mould, it is necessary to detect the detonator shell on the mold to ensure that the mold is filled with the detonator shell, so as to avoid the occurrence of empty film, causing explosives to be lo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B07C5/34B07C5/36

CPCB07C5/3404B07C5/362

Inventor 刘颢陈池钦朱浩江国华黄嵩肖建明刘振茂陆海东程健黄方兵李泉铭邓云云龙波

Owner GUIZHOU PANJIANG CIVIL EXPLOSIVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com