Fuel cell hydrogen test system and test method

A fuel cell and test system technology, applied in the direction of fuel cells, fuel cell control, fuel cell additives, etc., can solve the problems of low analysis efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

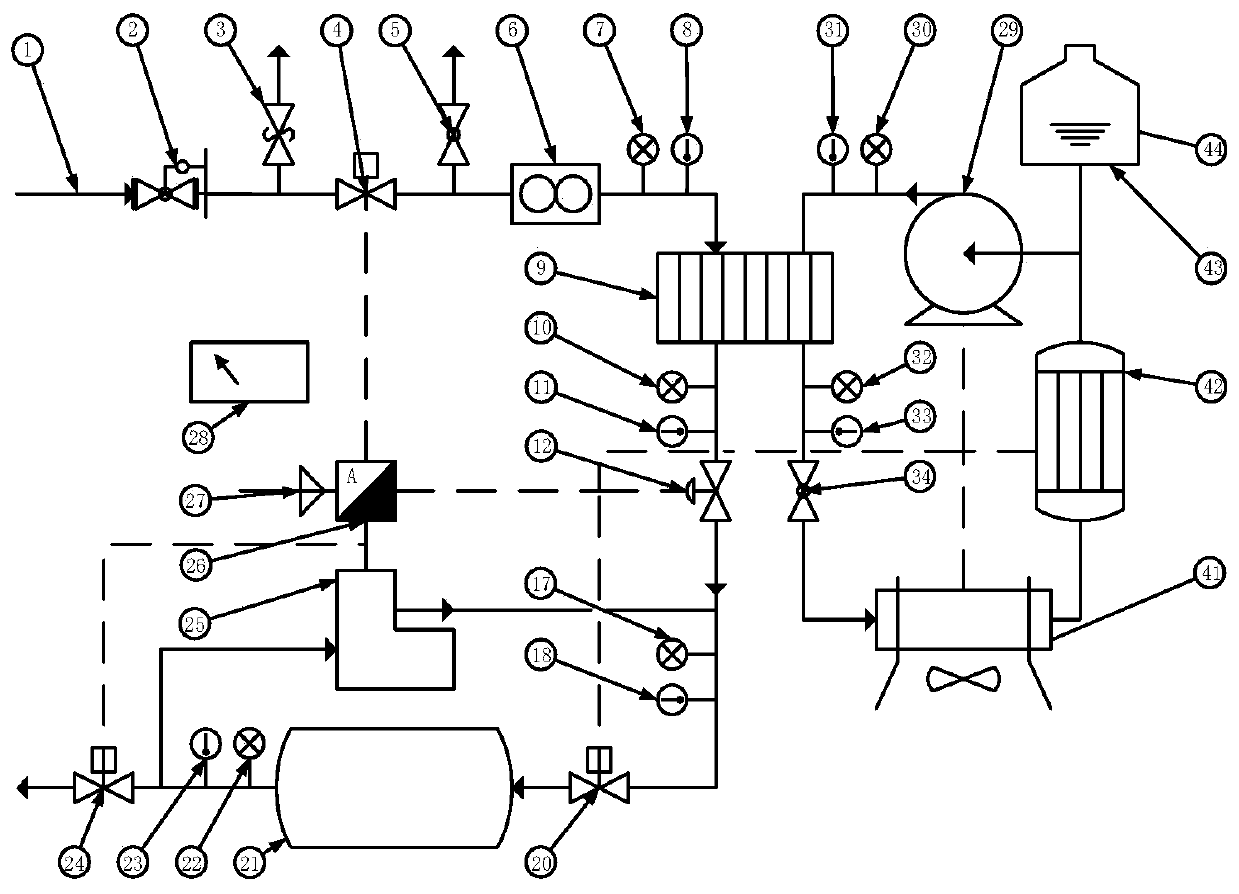

[0108] This implementation discloses a fuel cell hydrogen test system, such as figure 1 As shown, the fuel cell hydrogen test system includes: a heat exchanger 9 , a stack simulator 21 , a water supply module, a hydrogen supply module and a hydrogen circulation pump 25 . Wherein, the heat exchanger 9 has a first hydrogen flow channel and a first water flow channel, and the stack simulator 21 is used to simulate the stack under the working condition to be tested. The water supply module comprises a heating water tank 42, a booster pump 29 and a radiator 41, and the booster pump 29 is connected between the outlet of the heating water tank 42 and the inlet of the first water flow passage through a pipeline, so that the heated water in the heating water tank 42 The water 44 sucked out and pressurized is sent to the inlet of the first water channel, and the outlet of the first water channel is connected to the inlet of the heating water tank 42 through a pipeline. The hydrogen sup...

Embodiment 2

[0133] The structure of the fuel cell hydrogen test system in this embodiment is basically the same as that of the fuel cell hydrogen test system in Example 1. Simulation of the humidification function. Wherein, the same reference numerals in this embodiment and the first embodiment refer to the same elements.

[0134] like image 3 As shown, the fuel cell hydrogen test system further includes a humidifier 16 , and the humidifier 16 is located between the proportional valve 12 and the stack simulator 21 , and between the heat exchanger 9 and the heating water tank 42 . Wherein, the humidifier 16 has a second hydrogen flow channel and a second water flow channel, and the humidifier 16 is used for unidirectionally permeating the water passing through the second water flow channel to the second hydrogen flow channel. A water flow meter 39 is provided between the outlet of the second water channel and the heating water tank 42 . The hydrogen circulation pump 25 is connected bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com