A driving mechanism of a coaxial cable jig

A driving mechanism and coaxial cable technology, applied in the direction of circuits, electrical components, circuit/collector components, etc., can solve the problems of inability to cut rings, and achieve the effect of easy processing and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

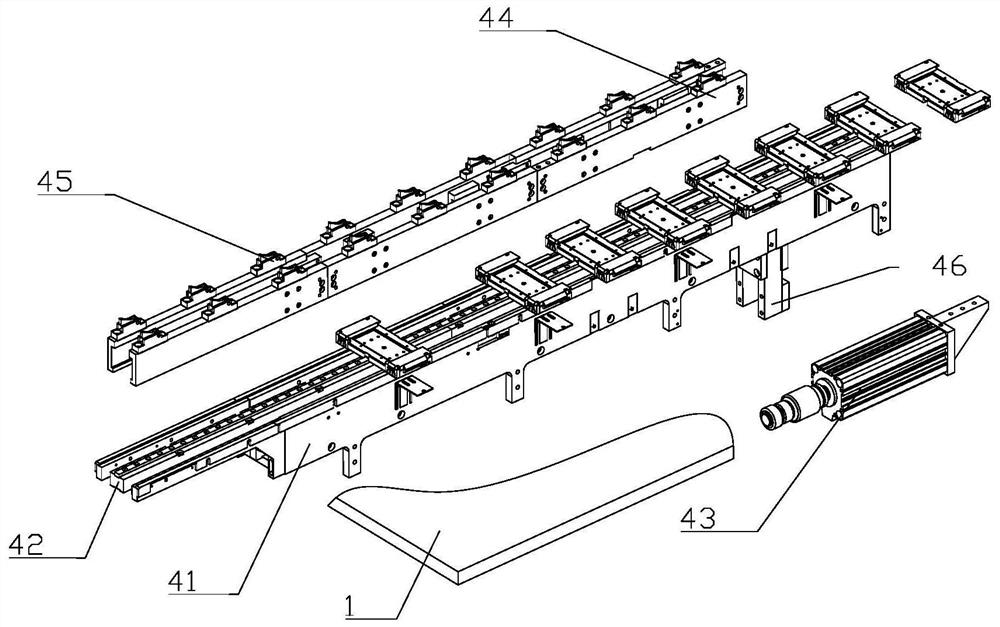

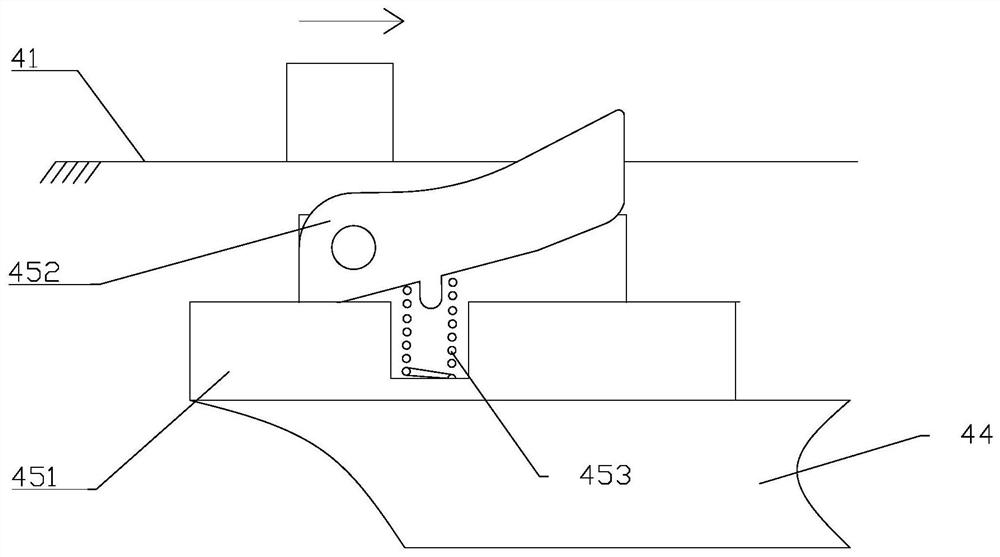

[0019] Such as figure 1 As shown, a driving mechanism of a coaxial cable jig includes a fixed base 41, an intermediate slide bar 42, a material transfer cylinder 43, a sliding plate 44, a pushing assembly 45, a connecting block 46 and a cable jig; the fixed bottom plate 41 is fixed Set on the frame, the fixed base 41 is groove-shaped, the middle sliding bar 42 is installed in the middle of the fixed base 41, and the middle sliding bar 42 is convex; the material-moving cylinder 43 is horizontally arranged on the frame, and the material-moving cylinder The telescopic end of 43 is connected with the sliding plate 44 through the connecting block 46; the sliding plate 44 is moved and matched with the fixed base 41 through the slide rail, and the sliding plate 44 is provided with two parallels; the pushing material The components 45 are arranged on the upper end of the sliding plate 44, and the pushing components 45 are evenly arranged, and the corresponding pushing components 45 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com