Automobile door glue coating frame

A technology for car doors and glue racks, which is applied to coatings and devices for coating liquid on the surface, etc. It can solve the problems of colloid quality defects, energy consumption, and easy fatigue, so as to improve the efficiency and accuracy of glue coating and ensure the coating quality. The effect of glue quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

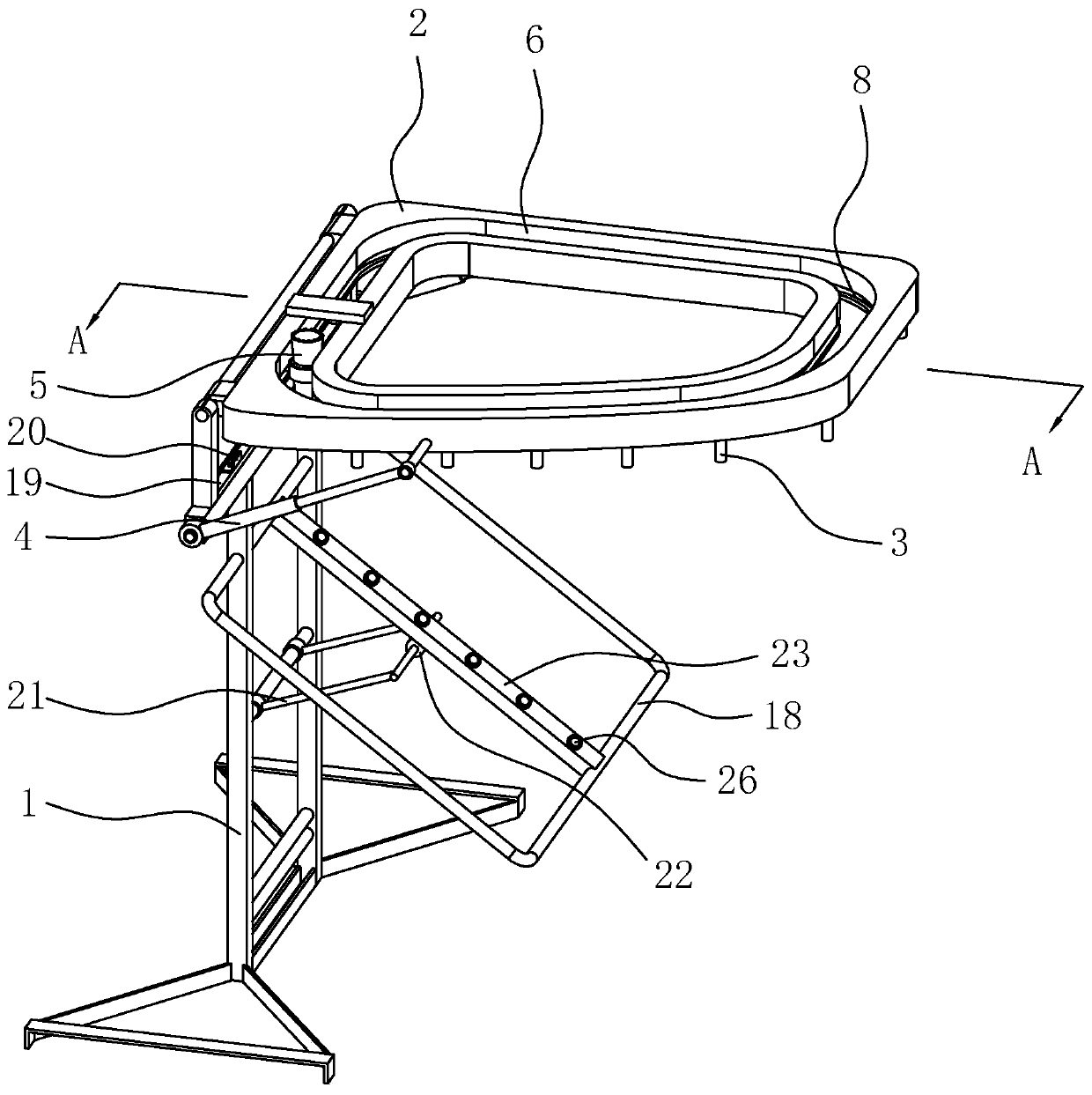

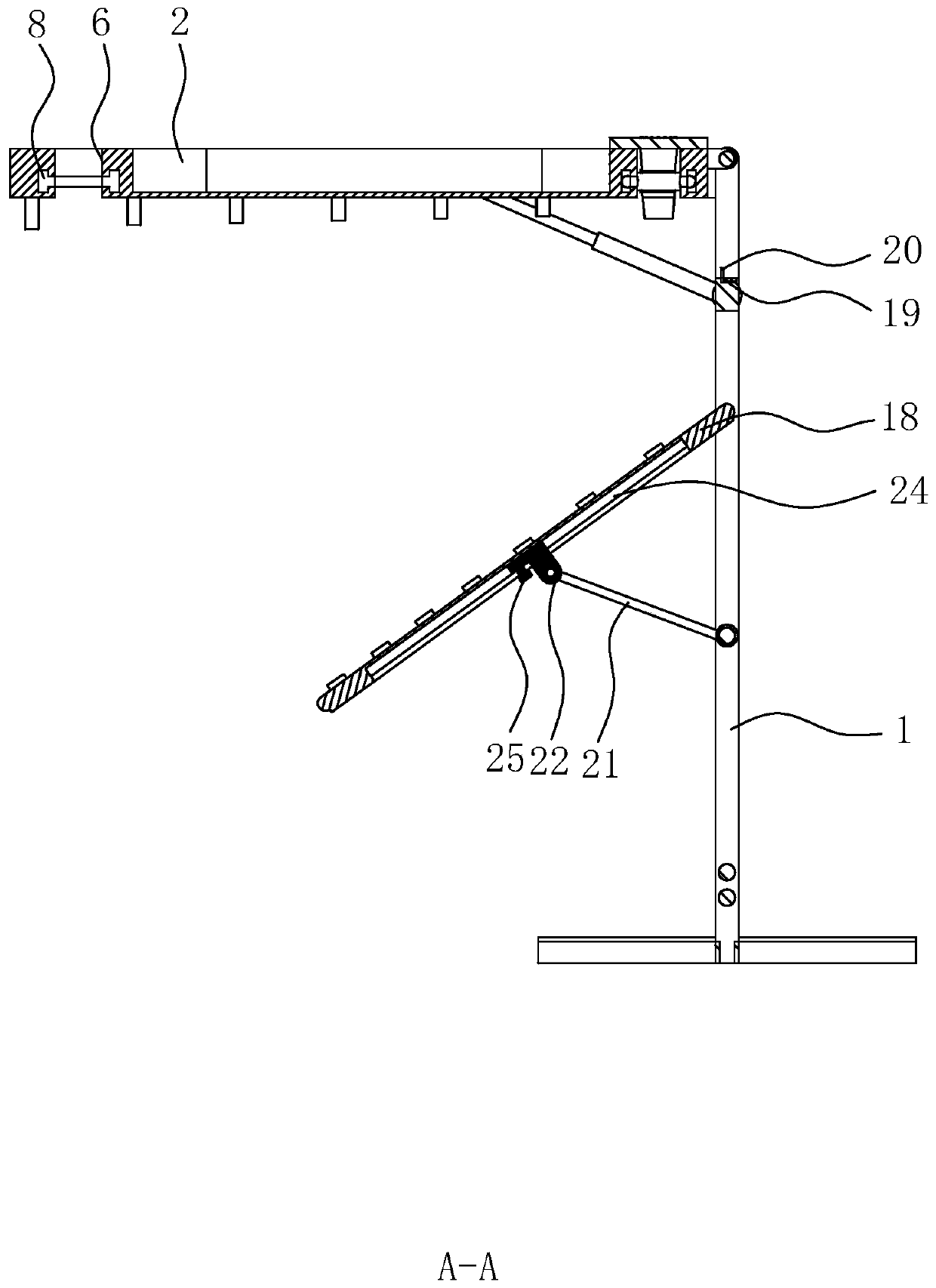

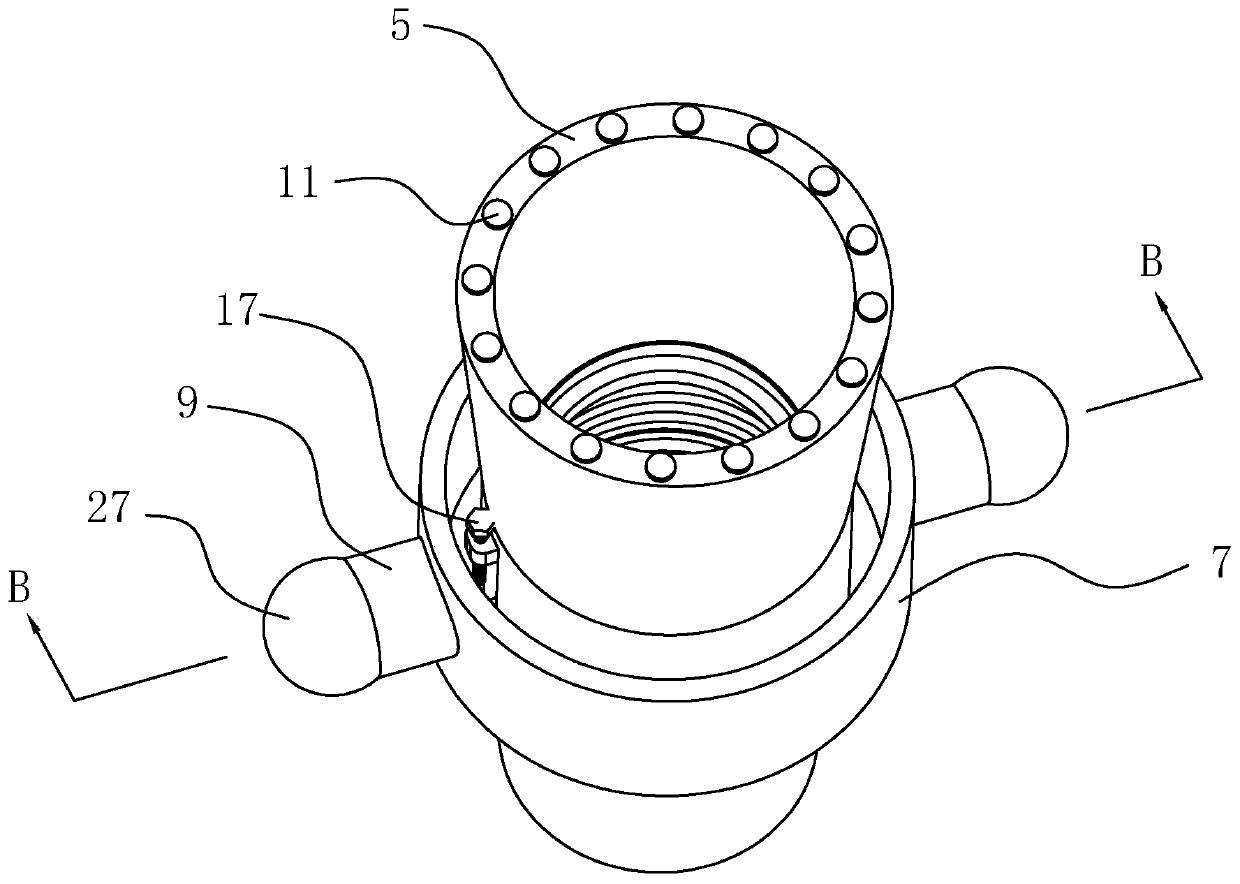

[0038] refer to figure 1 and image 3 , is an automobile door gluing frame disclosed by the present invention, comprising a vertically arranged frame body 1, a positioning device for positioning the door to be glued is arranged on the frame body 1, and a contour and a frame to be glued are arranged on the upper end of the frame body 1 The track frame 2 adapted to the three-dimensional trajectory of the glued part of the glued car door, the lower end of the track frame 2 is fixed with a plurality of pressure columns 3 corresponding to the depressions of the door to be glued, and a gas spring is arranged between the frame body 1 and the track frame 2 4. There are two gas springs 4, and one end is hinged with the side wall of the frame body 1 and the other end is hinged with the side wall of the track frame 2; the track frame 2 is provided with a chute 6 along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com