Water pump with long service life and high sealing performance and assembling method

An assembly method and a high-sealing technology, which are applied to components, pumps, assembly machines, etc. of pumping devices for elastic fluids, can solve the problems of high-sealing water pump piston parts stuck in motion, short service life of water pumps, and excessive seal leakage rate To achieve safe and reliable installation status, reduce the difficulty of installation and adjustment, and prevent components from being scrapped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0038] The present invention relates to assembly process technology, mainly including assembly process optimization design, digital measurement, performance test method optimization, resistance reduction and wear reduction and other technologies. Through the above technical methods, the precise assembly and performance optimization of the water pump can be realized, and each index can meet the index requirements. .

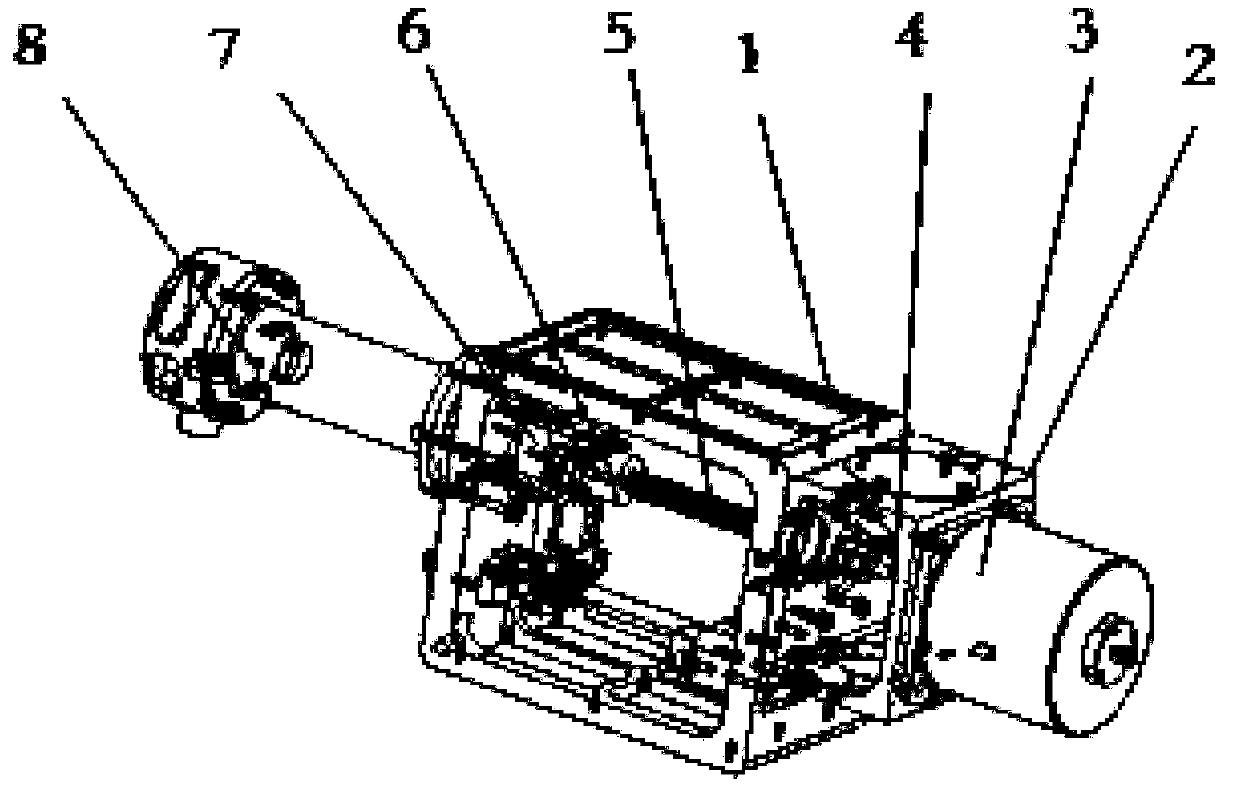

[0039] A long-life high-sealed water pump, comprising a pump body bracket 1, a motor bracket 2, a motor 3, a shaft coupling 4, a lead screw 5, a commutator 6, a piston 7, and a cylinder body 8; wherein, the pump body bracket 1 and the motor The bracket 2 is docked; the motor 3 is fixedly installed on the motor bracket 2, and the output shaft of the motor 3 points to the pump body bracket 1; the coupling 4 is arranged in the motor br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com