Aeration ball and fluidized bed applying same

A balloon and flow bed technology, applied in the field of aeration balls, can solve the problems of insufficient utilization of additives, influence of sewage treatment flow rate, slowdown of sewage treatment speed, etc., to achieve logarithmic growth of high activity, good chemical and biological stability , Strong bioadhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

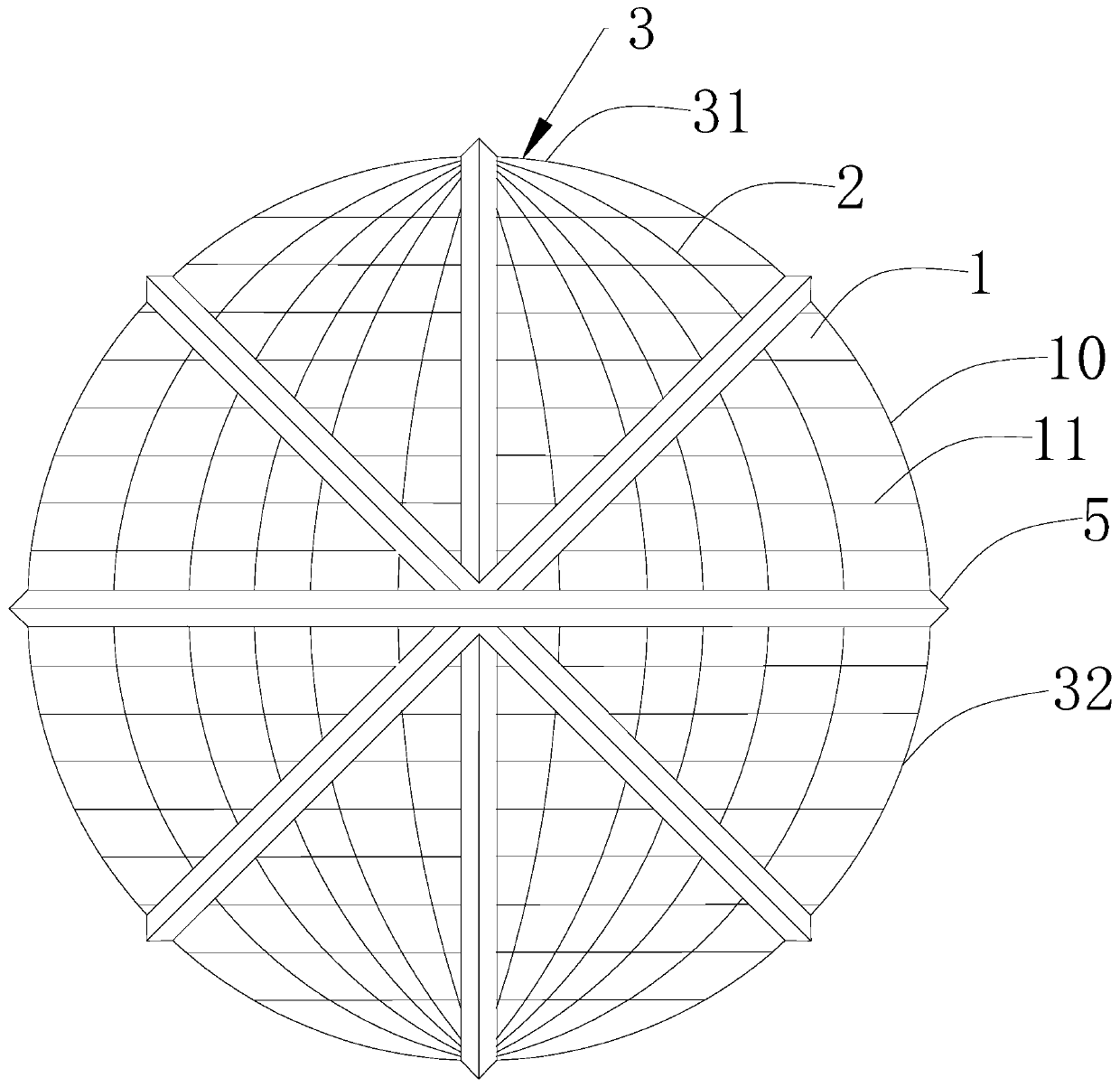

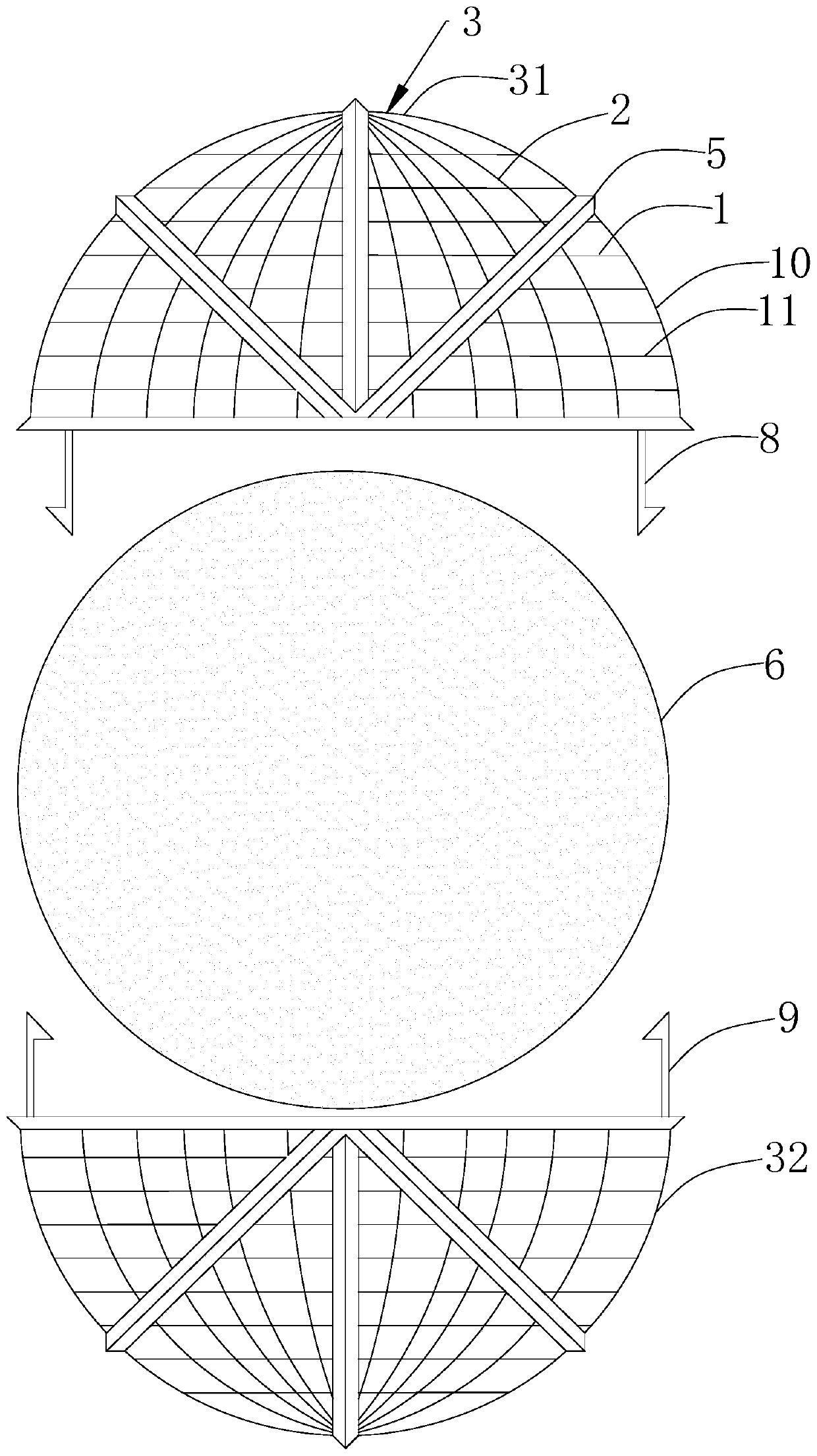

[0033] Embodiment one: a kind of aeration ball, such as figure 1 and figure 2 As shown, it includes an outer shell 3 with a spherical outer contour, an inner cavity 2 is opened in the outer shell 3, and a plurality of through holes 1 that can realize self-aeration of the water body are arranged on the spherical surface of the outer shell 3, and the through holes 1 are connected to Inner cavity 2; the inside of the inner cavity 2 is provided with a filter filler block 6 for water filtration.

[0034]The inner cavity 2 can not only make the inner structure of the outer shell 3 hollow, but also make the outer shell 3 be divided into inner and outer layers; secondly, since the number of through holes 1 is several and runs through the outer shell 3, the through holes 1 A fishnet-like penetrating structure can be formed on the outer shell 3; and the filter layer for sewage filtration is installed in the inner cavity 2, so that the outer shell 3 has strong bioadhesion, large specif...

Embodiment 2

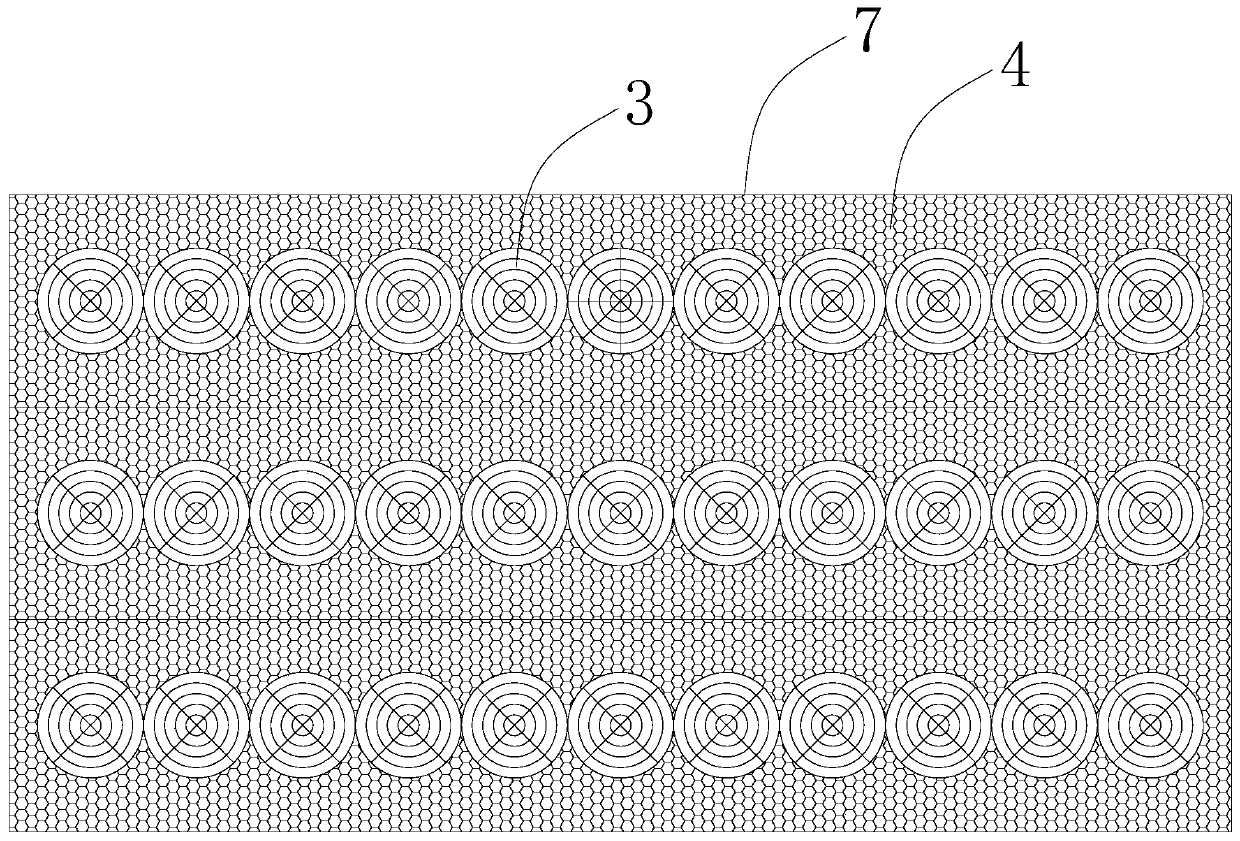

[0041] a fluid bed, such as Figure 1 to Figure 3 As shown, it includes an aeration ball and a bed body 7 for sewage treatment, and the bed body 7 is a fluidized bed commonly used in the field of sewage treatment. The outer casing 3 is arranged in the bed body 7 through the packed filter layer 4. The number of outer shells 3 is at least one and is evenly distributed along the axial direction of the bed body 7, and the filter layer is a filler capable of filtering water. By covering all corners of the bed body 7 evenly and fully with the outer casing 3, the bed body 7 can maintain good biological activity and void variability, and can obtain larger and larger specific surface areas during the operation process, while being able to Have a good metabolism. Secondly, by combining an aeration ball with the flow bed, the biomass per unit volume in the bed body 7 can also be increased, thereby achieving the purpose of short hydraulic flow residence time. Secondly, it is also conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com