A column and its connection method with external beams

A connection method and corner technology, applied in the direction of columns, pillars, pier columns, etc., to achieve the effects of simple and flexible setting, reducing welding points and welding times, increasing rigidity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. For the convenience of description, the orientations such as up, down, left, and right in the views are directly used in the following detailed description process, and are used to indicate the positions of the various components in the figure. This orientation description is not limiting.

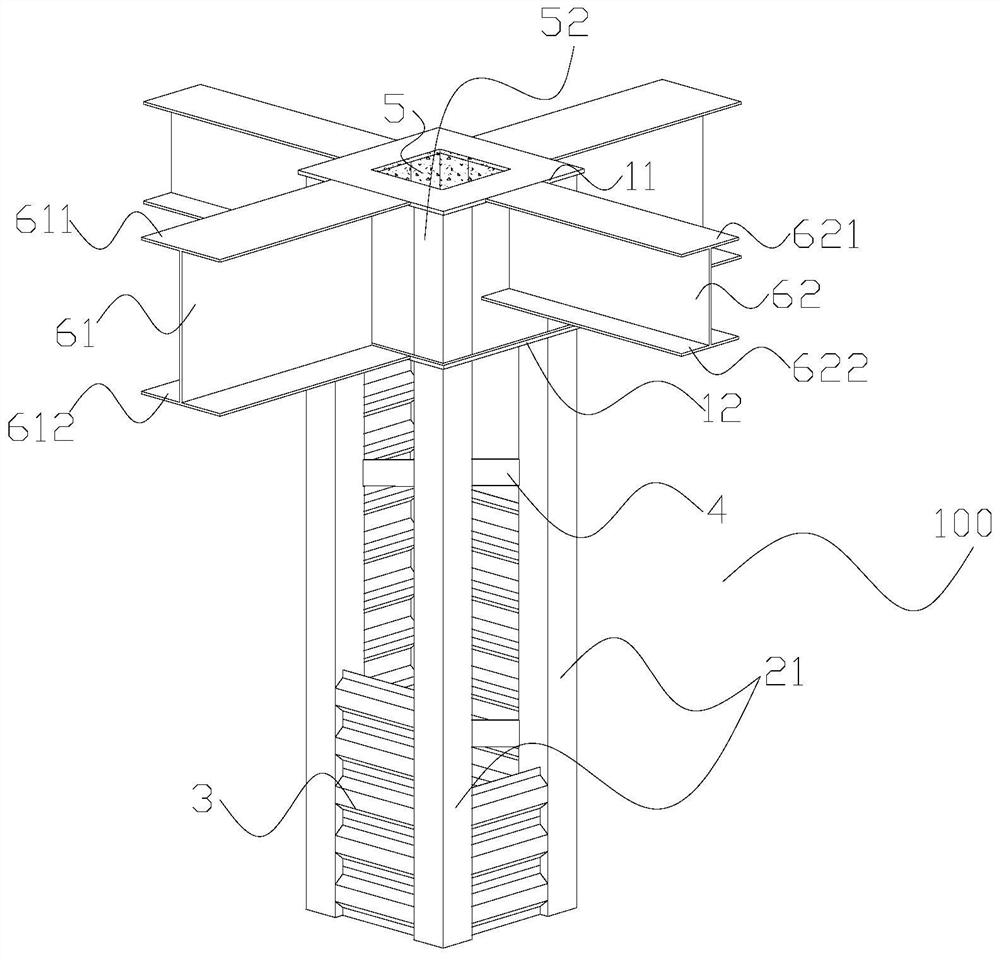

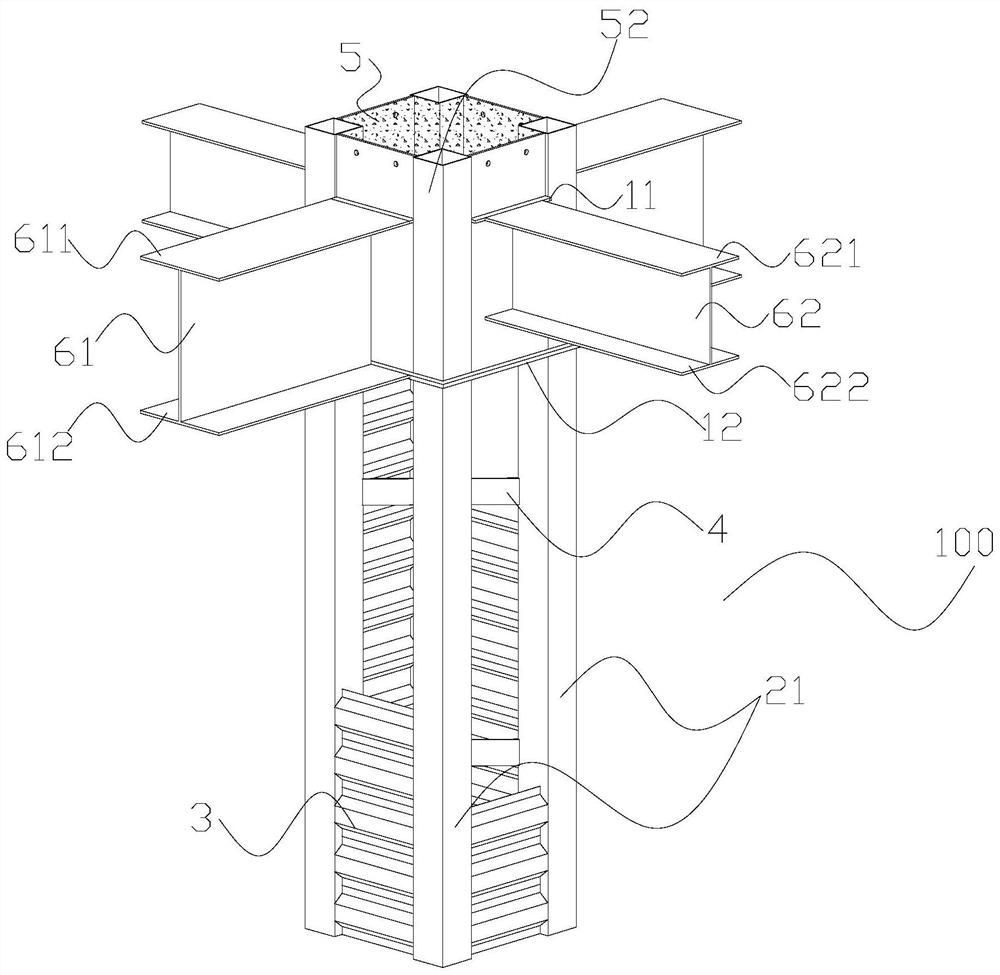

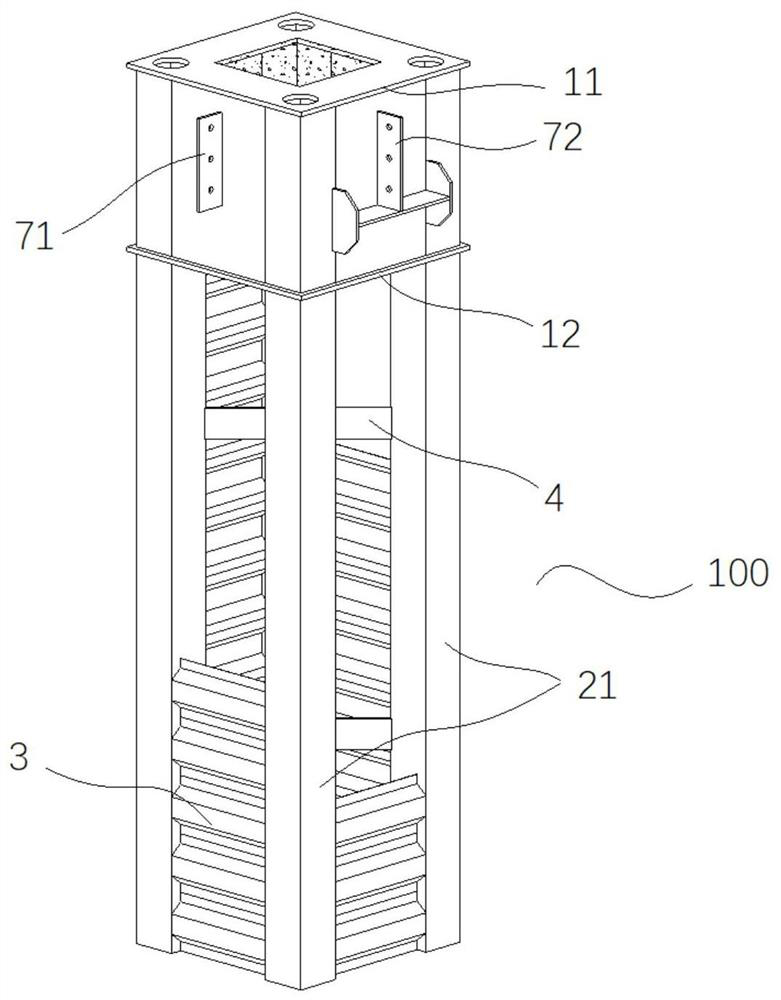

[0039] like Figure 2A As shown, the present invention provides a preferred column 100 comprising four corner steel tubes 21, each corner steel tube 21 being preferably a rectangular steel tube, and most preferably a square steel tube. Side plates, preferably corrugated side plates 3 , are arranged between adjacent corner steel pipes 21 . For the corner steel pipe 21 and the corrugated side plate, various connection methods can be used, such as welding. The setting of the wave height and wave spacing of the corrugated side plate 3 can be selected according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com