A rotary automatic welding robot and its welding method

An automatic welding and robot technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex structure, automatic positioning welding, bulky and bulky, etc., to improve the range of machinability and ensure welding accuracy , Guarantee the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

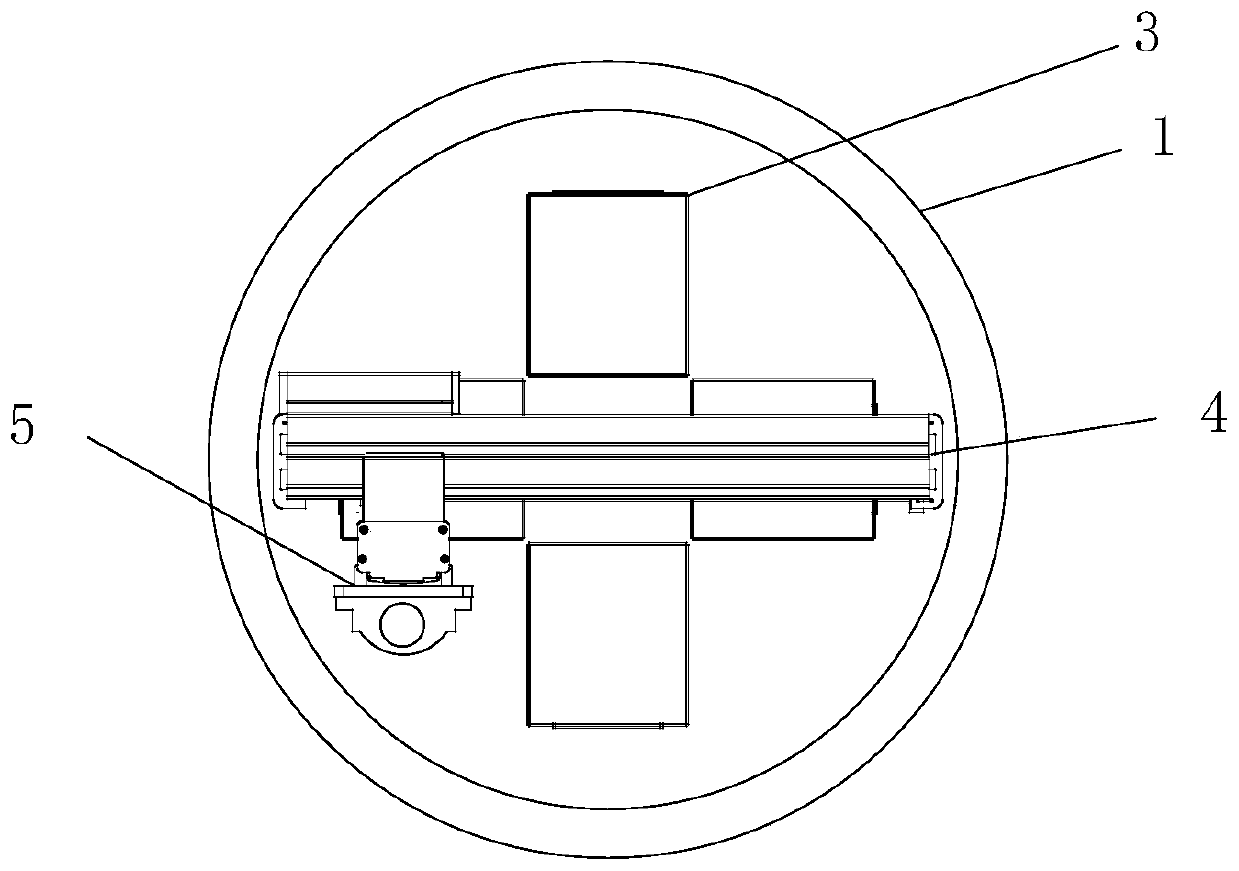

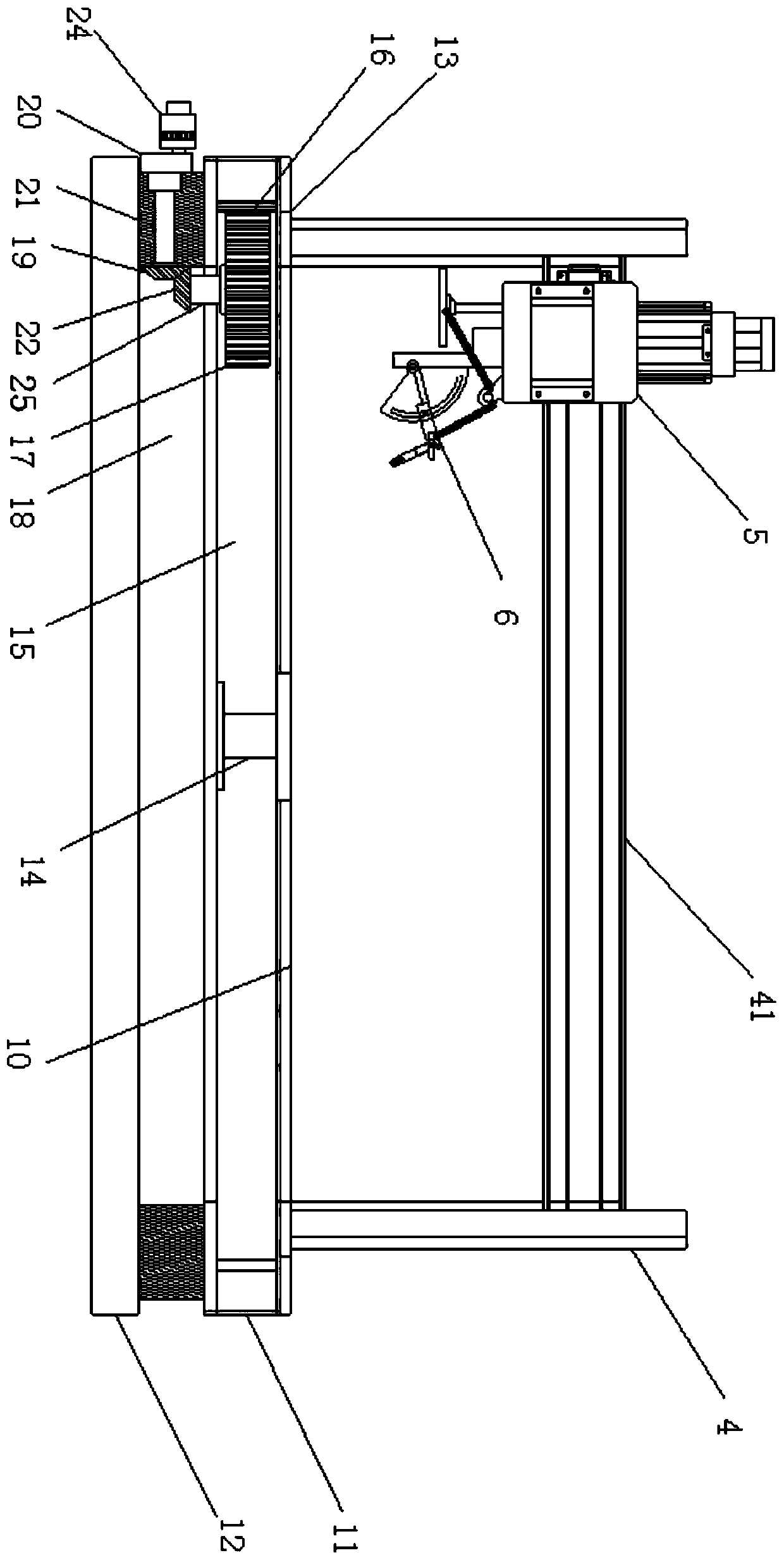

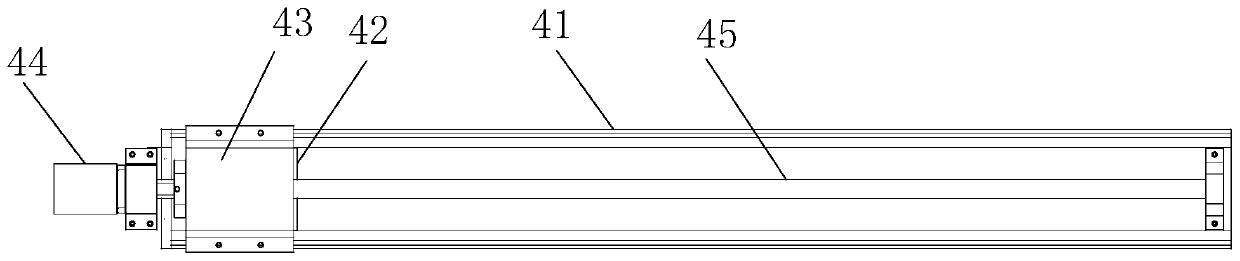

[0036] see figure 1 and figure 2 , a rotary automatic welding robot and welding method thereof, comprising a rotary base 1, a working frame 4 is installed on the rotary base 1, a Y-axis guide rail 41 is installed on the working frame 4, and the Y On the shaft guide rail 41, an adjustment frame 5 is movably installed, and a Z-axis guide rail 51 is installed on the adjustment frame 5, and a welding frame 6 is movably installed on the Z-axis guide rail 51, and the rotary base 1 A bearing platform 10 is fixedly installed on the upper surface of the bearing platform 10, and several jig plates 3 are arranged on the bearing platform 10.

[0037] In this application, the rotary base 1 is the reference plane for the welding operation, the operation frame 4 is the supporting frame for the welding operation, the Y-axis guide rail 41 adjusts the Y-axis coordinate, and the Z-axis guide rail 51 adjusts the Z-axis coordinate. 6 for welding operations. The fixture plate 3 is detachably in...

Embodiment 2

[0047] see Figure 5 , this embodiment serves as a further optimization of the first embodiment, on the basis of which, in order to further improve the precision of the welding process, the present application also adds an adjustment mechanism on the welding frame 6 .

[0048] A fixed base frame 61 is installed on the welding frame 6, a support plate 62 is installed on the top of the fixed base frame 61, and a swing to the frame 63 is installed on the support plate 62 through a movable shaft, and the swing to the frame A welding gun 64 is installed on the 63, an angle measurement plate 65 is also installed on the support plate 62, an arc-shaped groove 66 is arranged on the angle measurement plate 65, and the swing direction frame 63 is installed on the arc-shaped Inside the groove 66.

[0049] The fixed base frame 61 has a built-in adjusting motor, the driving end of the adjusting motor is equipped with a motor shaft 68, and the top of the motor shaft 68 is equipped with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com