Pharmaceutical medicine particle screening equipment

A screening equipment and sieve plate technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of inconvenience for users, affect the screening efficiency, reduce the use efficiency, etc., and achieve the effect of novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] see Figure 1~3 , in an embodiment of the present invention, a kind of equipment for screening pharmaceutical drug particles, including a buffer chamber 1 and a screening chamber 3; the upper end of the buffer chamber 1 is provided with a feed hopper 2 communicating with it, and the screening chamber 3 is arranged in the buffer chamber 1 The lower end of the sieve plate 4 is connected to the lower end of the sieve cavity 3 through the drop hole 21. The sieve plate 4 is driven by the first drive assembly to move up and down reciprocally. The sieve plate 4 is provided with a plurality of holes for qualified medicine particles to fall A sieve hole 5, the bottom of the sieve plate 4 is provided with a guide plate 7 driven by the second drive assembly to move up and down, and the upper end of the guide plate 7 is provided with a plurality of tamping rods 6, and one of the tamping rods 6 is located in one Directly below the sieve hole 5, when the guide plate 7 moves upward, t...

Embodiment 2

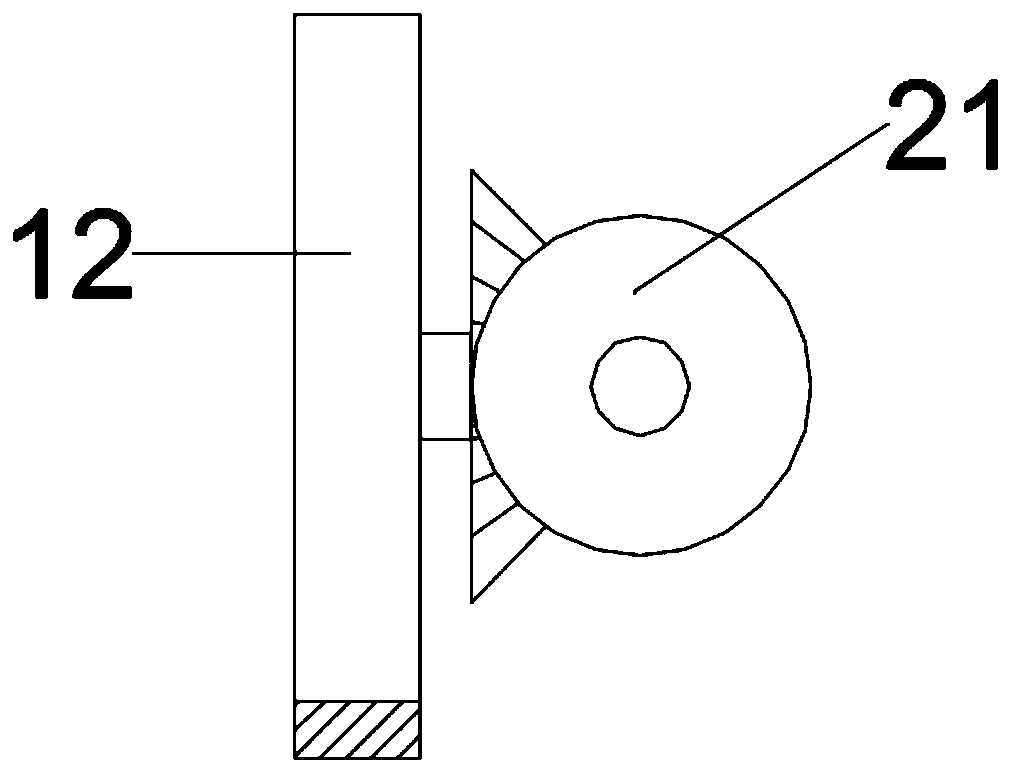

[0030] see Figure 4 In the actual implementation process, the present invention provides another embodiment to improve the present application. Specifically, a baffle 19 is slidably installed at the junction of the buffer chamber 1 and the screening chamber 3, and one end of the baffle 19 is connected to the blanking The inner wall of the hole 21 contacts, and the other end is slidingly connected with the second eccentric wheel 20 fixed on the rotating shaft 16. When the rotating shaft 16 rotates, it drives the baffle plate 19 to move reciprocally, thereby realizing the reciprocating opening and closing of the blanking hole 21, realizing The medicine particles in the buffer chamber 1 are fed intermittently, so as to prevent a large amount of medicine particles from being above the sieve plate 4 and affect the screening efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com