A low-voltage bypass copper busbar

A technology of copper busbars and busbars, applied in the direction of circuits, power cables, cables, etc., can solve the problems of increased resistance of busbars, large deformation of the outer ring, increased heat generation, etc., to save costs and reduce the use of copper materials , to ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

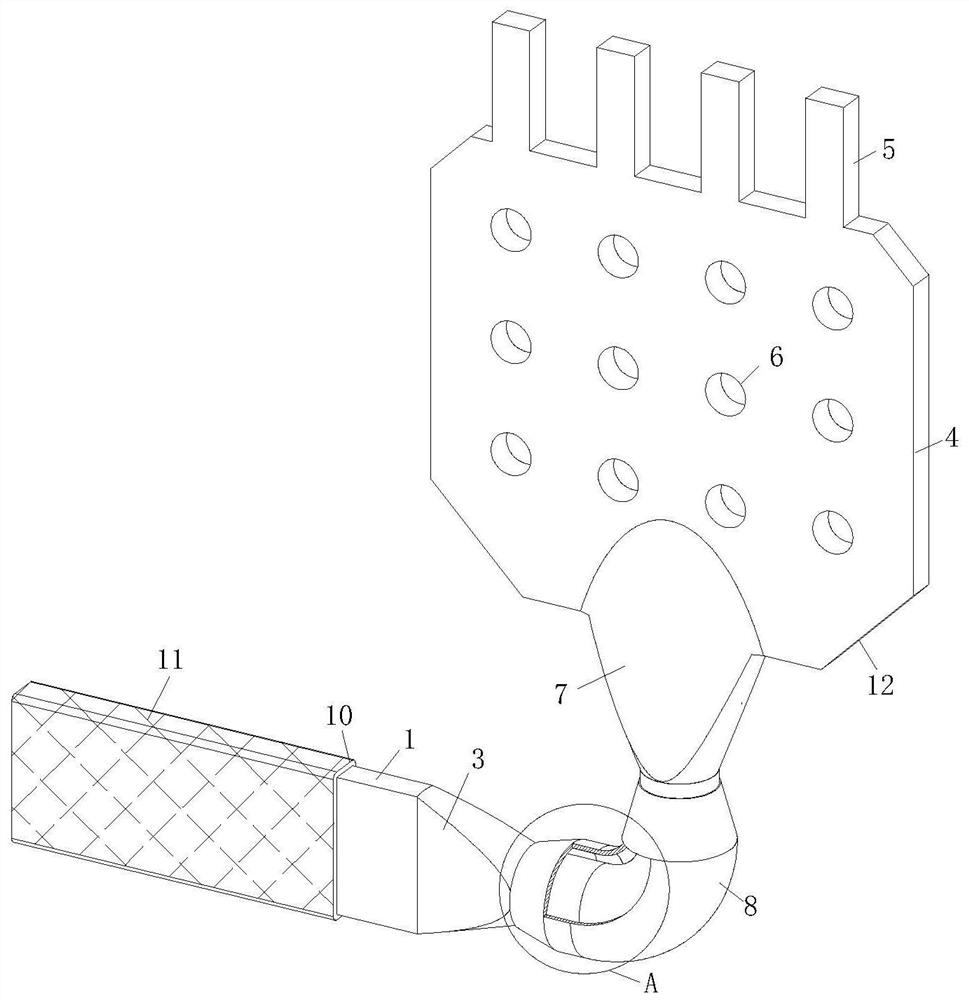

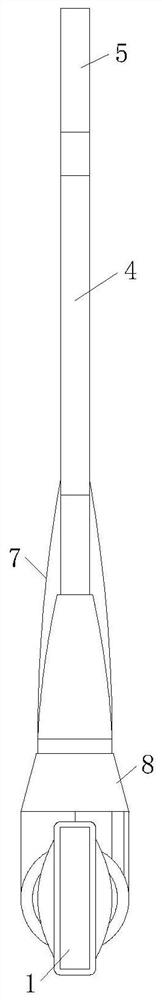

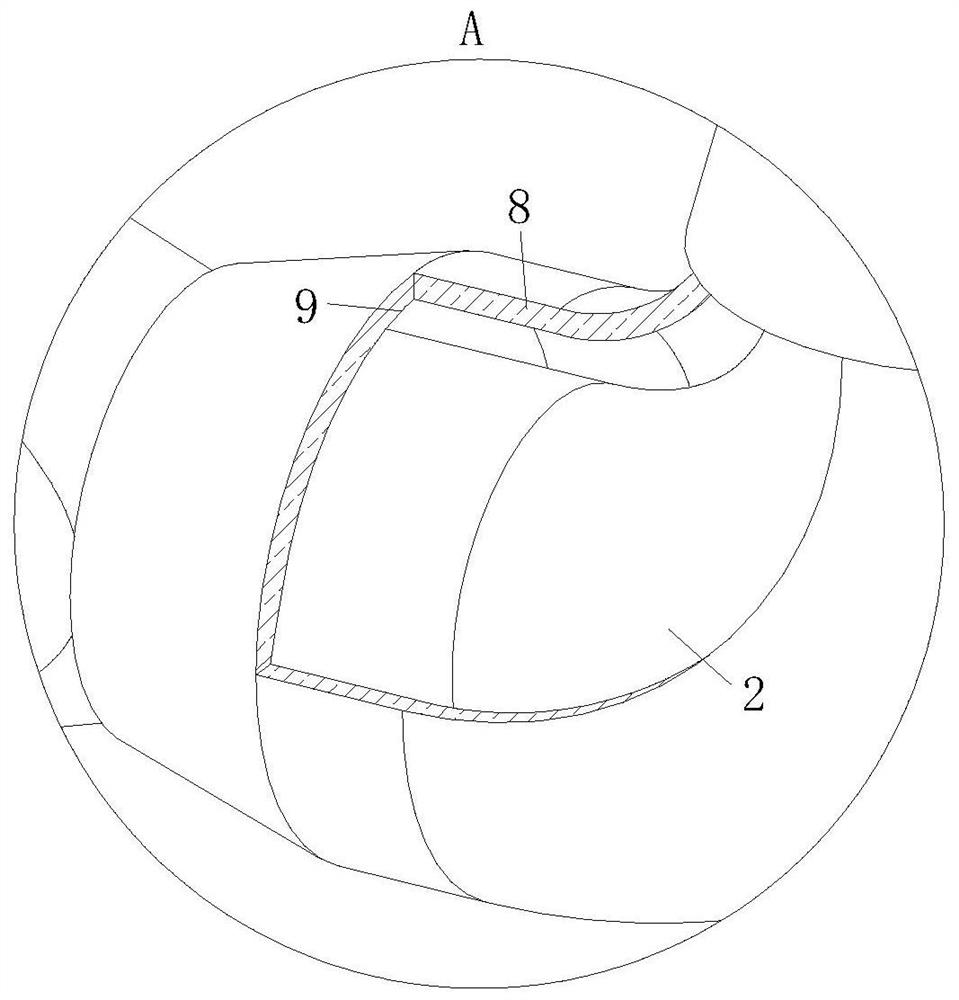

[0032] Such as Figure 1 to Figure 3 As shown, a low-voltage bypass copper busbar according to the present invention includes a busbar body 1, and the cross section of the busbar body 1 is a flat rectangular structure; The section 2 is a circular structure, and the vertical bending part 2 with a circular cross section has a small cross-sectional deformation during the cold bending operation; the No. 1 connection part 3 between the busbar body 1 and the vertical bending part 2 is formed by forging , the width of the No. 1 connecting part 3 is continuously reduced from the busbar body 1 to the vertical bend part 2, and the thickness is continuously increasing. The No. 1 connecting part 3 and the busbar body 1 and the vertical bend part 2 are smoothl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com