Multi-membrane reverse osmosis water-purifying system and water purifier

A water purification system and reverse osmosis technology, applied in osmosis/dialysis water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problem of high filter replacement cost, improve user experience, and improve pure waste ratio. , the effect of reducing the risk of scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

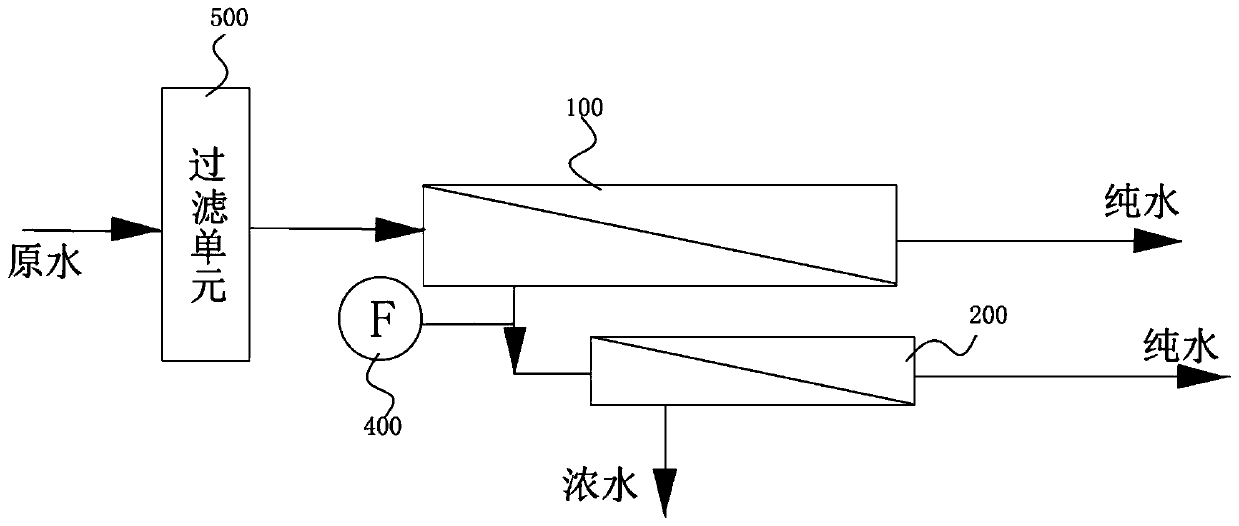

[0043] A multi-membrane reverse osmosis water purification system is provided with multi-stage membrane filtration units, and the concentrated water of the previous-stage membrane filtration unit is discharged into the water inlet of the next-stage membrane filtration unit as the water inlet of the next-stage membrane filtration unit. The last stage of membrane filtration unit concentrates on the concentrated water produced by the previous multistage membrane filtration units.

[0044]It should be noted that the main working principle of reverse osmosis water purification technology is to use reverse osmosis membrane (RO membrane) to treat the water entering the membrane, the purified water is discharged as pure water, and the concentrated water is discharged as wastewater. Reverse osmosis membrane water purification technology is common knowledge in this field, and the structure and working principle of the membrane filtration unit of the reverse osmosis water purification sys...

Embodiment 2

[0055] A multi-membrane reverse osmosis water purification system, other structures are the same as in Embodiment 1, the difference is that the preset threshold value of the flow sensor in this embodiment is that the concentrated water flow rate entering the second-stage membrane filtration unit reaches the first 1 / 3 of the total product water flow of the stage membrane filtration unit.

[0056] In the multi-mode reverse osmosis water purification system in this embodiment, by setting the threshold value of the flow sensor, the replacement time of the filter element of the last stage membrane filtration unit is strictly controlled. The pure waste ratio of the produced water is improved, and the user experience is improved.

Embodiment 3

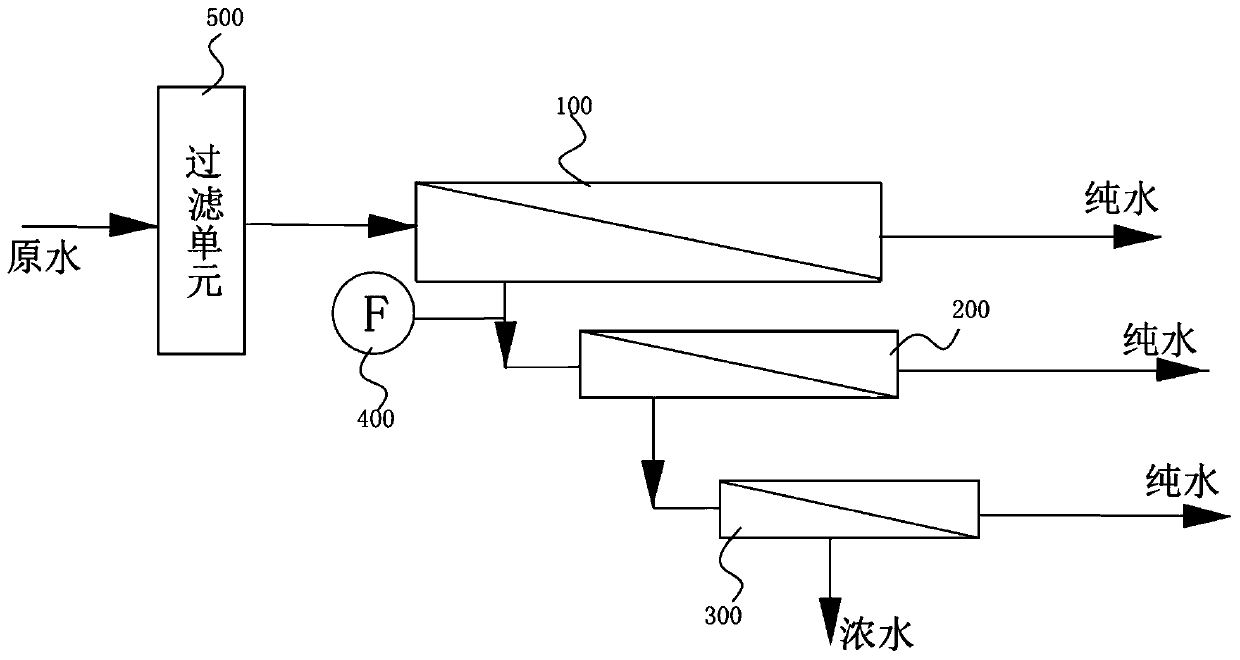

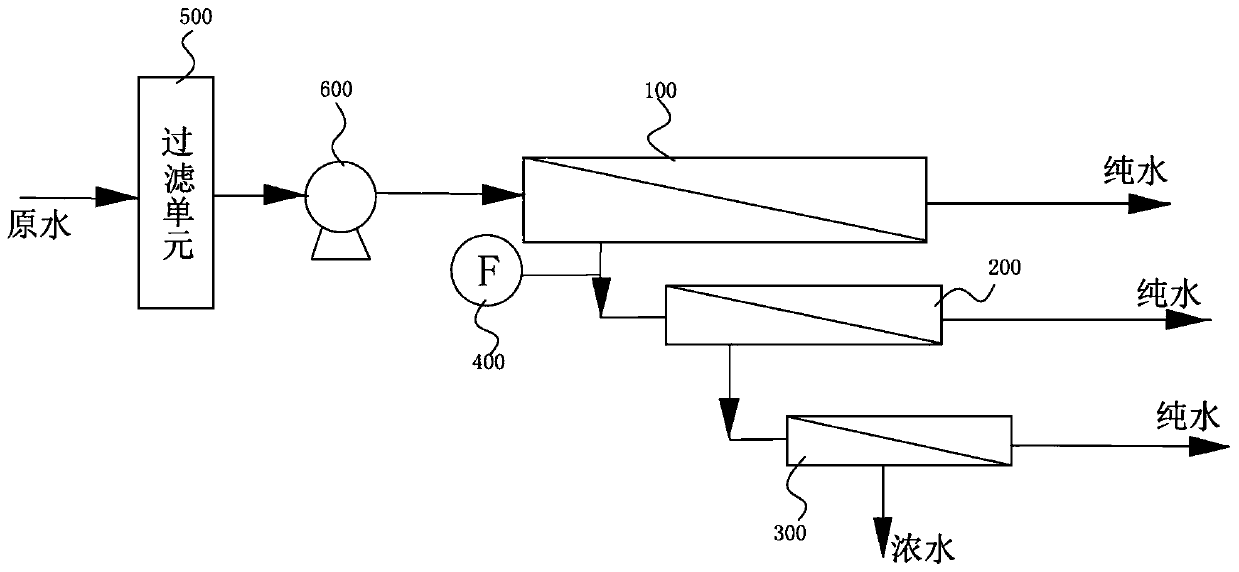

[0058] A multi-membrane reverse osmosis water purification system is provided with multi-stage membrane filtration units, and the concentrated water of the previous-stage membrane filtration unit is discharged into the water inlet of the next-stage membrane filtration unit as the water inlet of the next-stage membrane filtration unit. The last stage of membrane filtration unit concentrates on the concentrated water produced by the previous multistage membrane filtration units.

[0059] This embodiment takes a 3-stage membrane filtration unit as an example for illustration, as figure 2 As shown, a first-stage membrane filtration unit 100, a second-stage membrane filtration unit 200 and a third-stage membrane filtration unit 300 are provided, and the concentrated water of the first-stage membrane filtration unit 100 enters the water inlet of the second-stage membrane filtration sheet as The feed water of the second-stage membrane filtration unit 200 , the concentrated water of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com