A multi-stage rate regulation method for steam turbine feed-forward

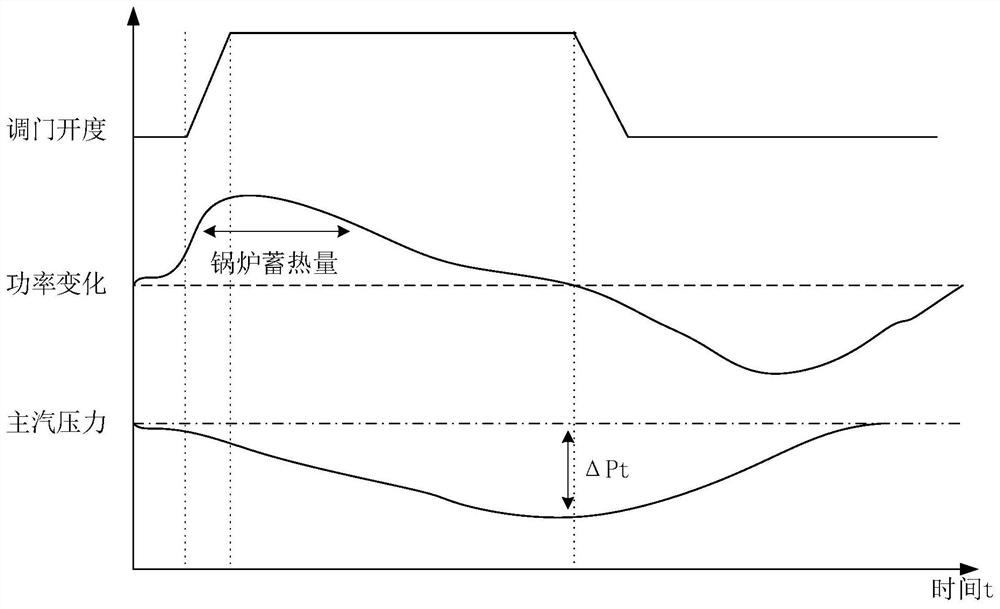

A speed regulation and steam turbine technology, applied in steam engine devices, mechanical equipment, engine components, etc., can solve the problems that the automatic gain control adjustment performance cannot meet the needs, etc., and achieve the effects of reducing overshoot, stable steam pressure, and increasing adjustment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

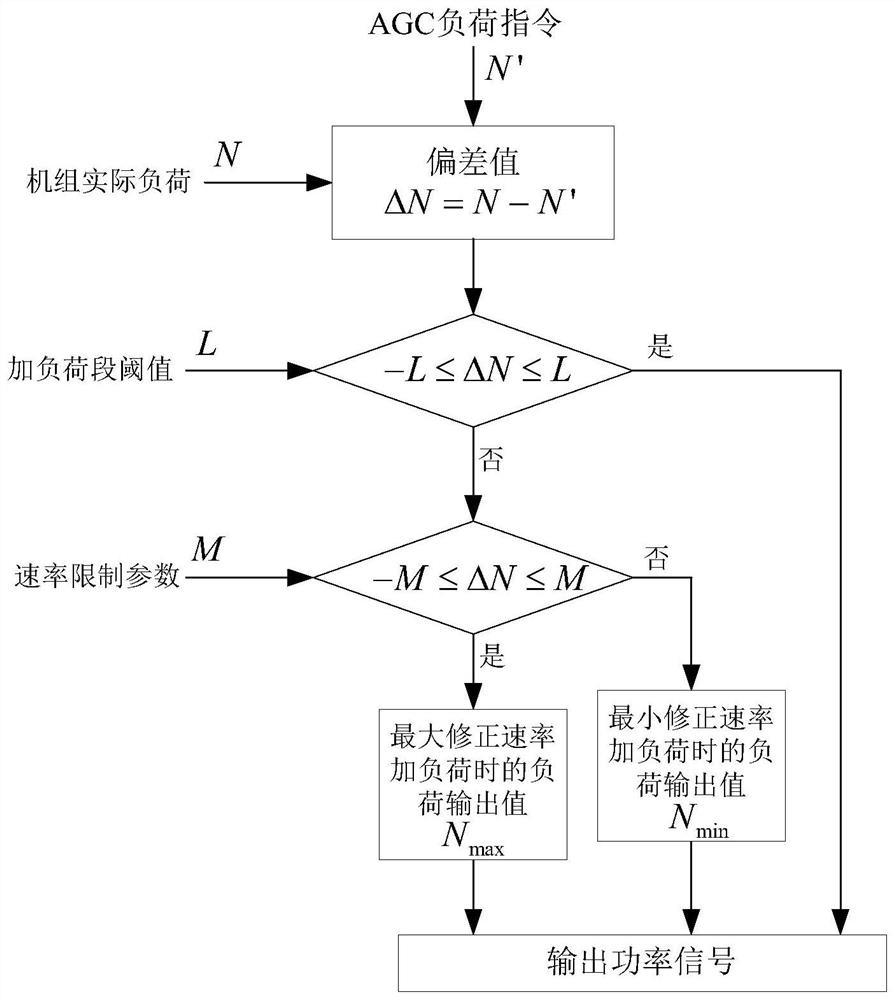

[0031] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the multi-stage rate adjustment method of steam turbine feed-forward described in this embodiment, the specific process of this adjustment method is:

[0032] S1. Obtain the AGC load command N' and the actual load N of the unit, and calculate the deviation value ΔN=N-N';

[0033] S2. Acquiring the loading segment threshold L;

[0034] S3. Determine the range of the deviation value ΔN. If it is -L≤ΔN≤L, the output power signal is the actual load N of the unit. If not, execute S4;

[0035] S4. Calculate the rate limit parameter M in real time;

[0036] S5. Judging the range of the deviation value ΔN, if it is -M≤ΔN≤M, then add the load output value N when the maximum correction rate is applied to the load max As the output power signal, otherwise the load output value N when the minimum correction rate is added to the load min as the output power signal.

[0037] In this em...

specific Embodiment approach 2

[0040] Specific implementation mode 2: This implementation mode further explains the implementation mode 1. The specific method for obtaining the loading segment threshold L described in S2 is:

[0041] L=1%×(35%~40%)×N 0 ;

[0042] Among them, N 0 Indicates the rated load of the unit.

[0043] In this embodiment, for the selection of the threshold value L of the load segment, the maximum deviation value of the unit during the adjustment process cannot exceed 1% of the rated load of the unit. Therefore, the threshold L of the load segment is based on 1% of the rated load of the unit. % to 40% (about 1 / 3) is used as the basis for judging whether to correct the power signal to the main controller of the steam turbine.

specific Embodiment approach 3

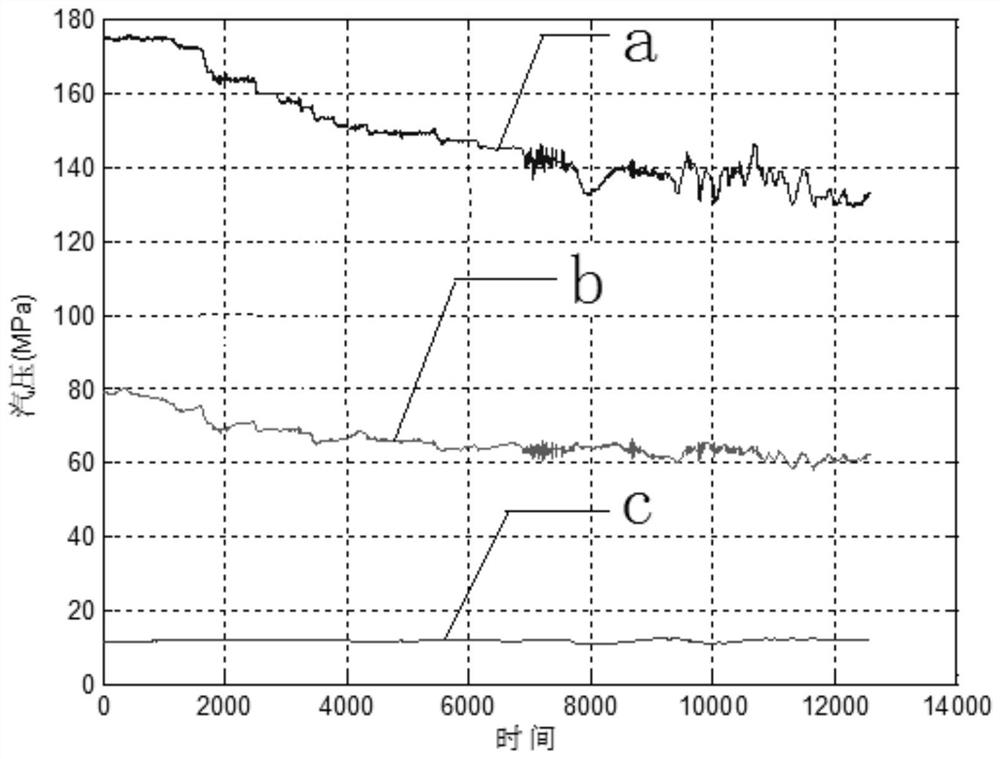

[0044] Specific implementation mode 3: This implementation mode further explains the implementation mode 1 or 2. The specific method for calculating the rate limit parameter M in real time as described in S4 is as follows:

[0045] M=d(C b (P dt -P d0 )) / dt;

[0046] Among them, P dt Indicates the minimum pressure of the unit, P d0 Indicates the load point pressure, C b Indicates the energy storage coefficient of the boiler.

[0047] In this embodiment, P dt Indicates the minimum pressure of the unit. When adding or subtracting load, take the 300MW unit as the benchmark, P dt Under the premise of avoiding the trigger lock increase and decrease of 0.6Mpa, the upper and lower fluctuations are ±0.1Mpa, and the minimum deviation is set to 0.5Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com