A stack-type rotating electrostatic generator

A generator and electrostatic technology, applied in the direction of induction generators, etc., can solve the problems of easy damage of the nanostructure on the surface of the friction layer, warping of sector disks, and affecting power generation efficiency, etc., achieve light weight, realize collection and utilization, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

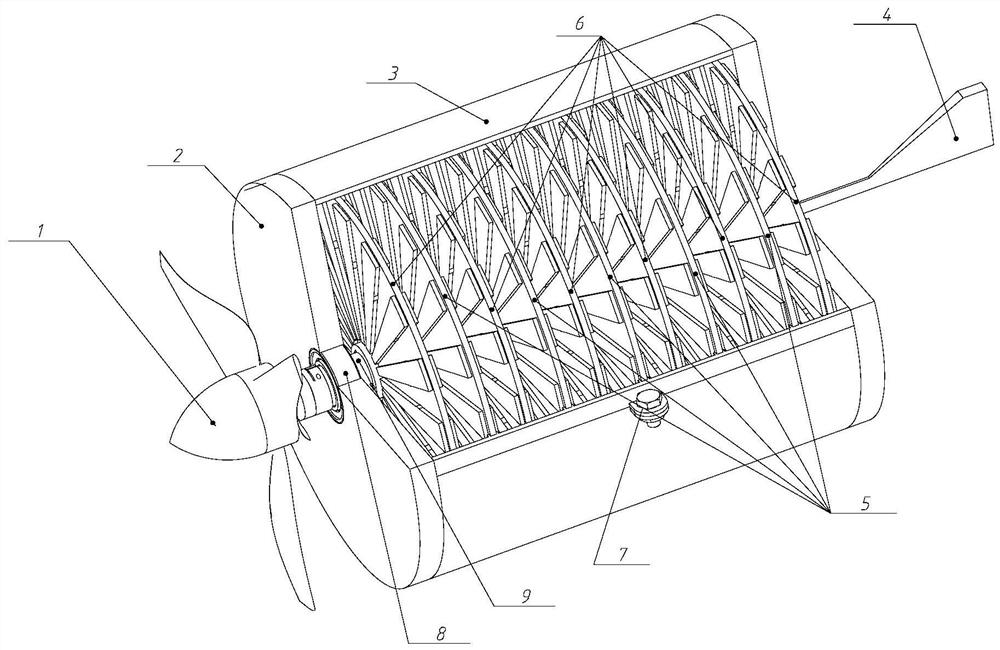

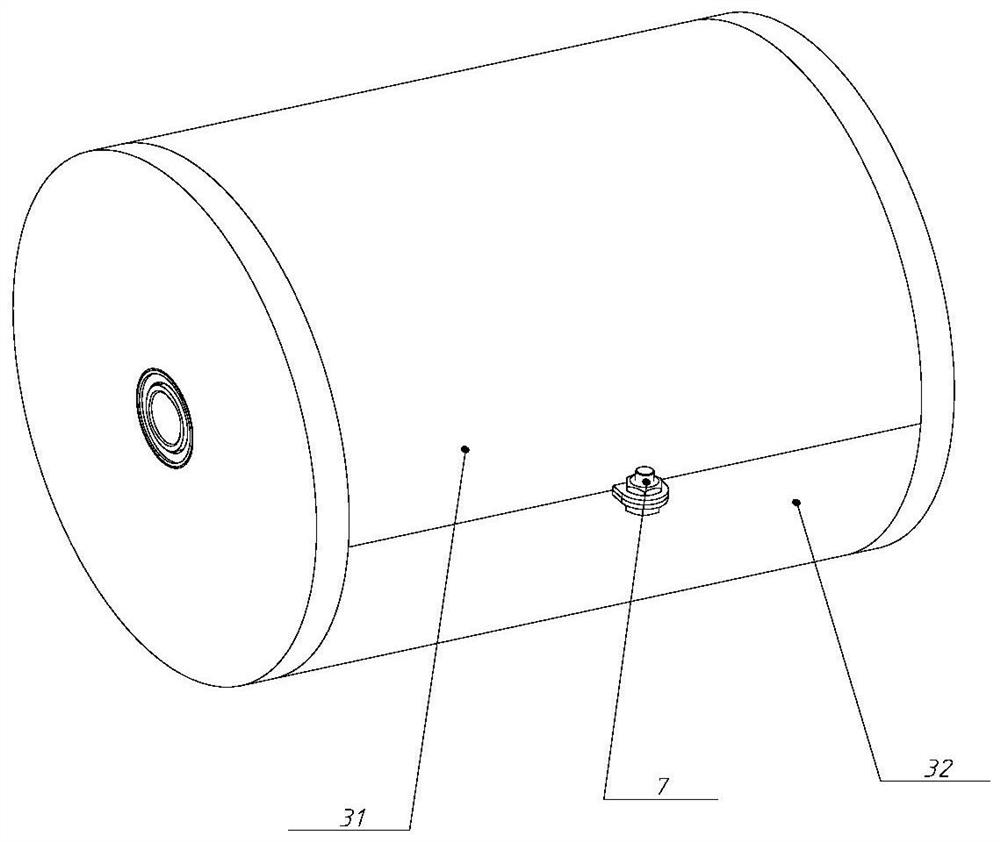

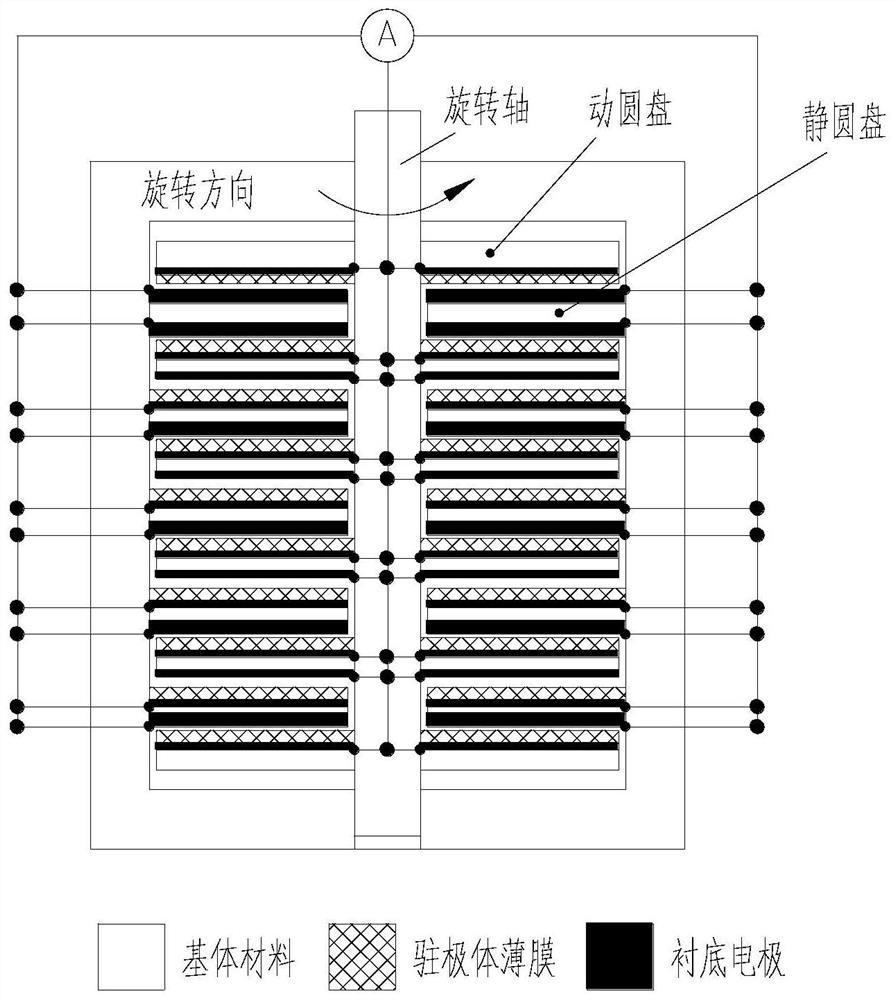

[0039] like figure 1 As shown, this embodiment provides a wind-induced stack-type rotating electrostatic generator, including: a power collection blade assembly 1, a bearing seat plate 2, a fixed cylinder 3, a tail 4, a moving disc 5, a static disc 6, a connection The screw assembly 7, the oil seal bearing 8, the rotating shaft 9; the fixed cylinder 3 is composed of two identical semi-cylindrical structures, which are fixed into an integral cylinder by the connecting screw assembly 7, which includes a hexagonal head bolt, a flat gasket, a hexagonal The head nut and the lugs set on the straight edge of the semi-cylindrical structure, among which, M3×8 bolts, M3 nuts and washers are selected; both ends of the fixed cylinder 3 are closed by the bearing seat plate 2, and the bearing seat plate 2 is acrylic The outer diameter is 95-110mm, the middle hole is 19mm in diameter, and the thickness is 5-8mm; 5 moving discs 5 and 5 static discs 6 are coaxially staggered and installed on t...

Embodiment 2

[0049] Figure 9 A schematic structural diagram of the second embodiment of the present invention is shown. The power collection assembly 1 is replaced by a number of turbine propellers, and the rest of the components are the same as the first embodiment. After adjusting the direction of the power collection assembly, it can rotate under the drive of water flow, and then drive the rotating shaft to rotate, so that the said The moving disc 5 and the stationary disc 6 form relative motion in the rotation direction of the rotating shaft, that is, the facing area between the electret and the working electrode changes periodically, so that the Charge recombination, output current to the external circuit, and realize the collection of water flow energy. It can be used for real-time measurement of environmental water flow, and the generated electricity can also be stored in the energy storage element.

Embodiment 3

[0051] Figure 10 A schematic structural diagram of the third embodiment of the present invention is shown. The power collection part 1 is replaced with a blade that can collect vertical wind power, and the other parts are the same as the first embodiment. The vertical wind blade does not need to face the wind when the wind direction changes. Compared with the first embodiment, the design and installation of the tail can be omitted. The structure is simplified, and the gyro force of the wind blade against the wind is also reduced. The mechanical energy in the environment is converted into power for driving the rotating shaft 9 to rotate, and the rest of the working principle is the same as the previous embodiment, and finally the utilization of wind energy is realized.

[0052] The stack-type rotating electrostatic generator of the present invention can expand the output by stacking a plurality of power generating units, thereby increasing the output power of the generator. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com