Ultra-large type manual core box mold of v-type engine cylinder body and core making method

An engine cylinder and core box mold technology, applied in the field of sand casting, can solve the problems of difficult core assembly, increased manufacturing cost, easy deformation of mold appearance, etc., achieves convenient disassembly and core assembly operation, improves stability and reliability, Reduce the effect of assembly and disassembly and mold release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments, but this does not constitute any limitation to the present invention.

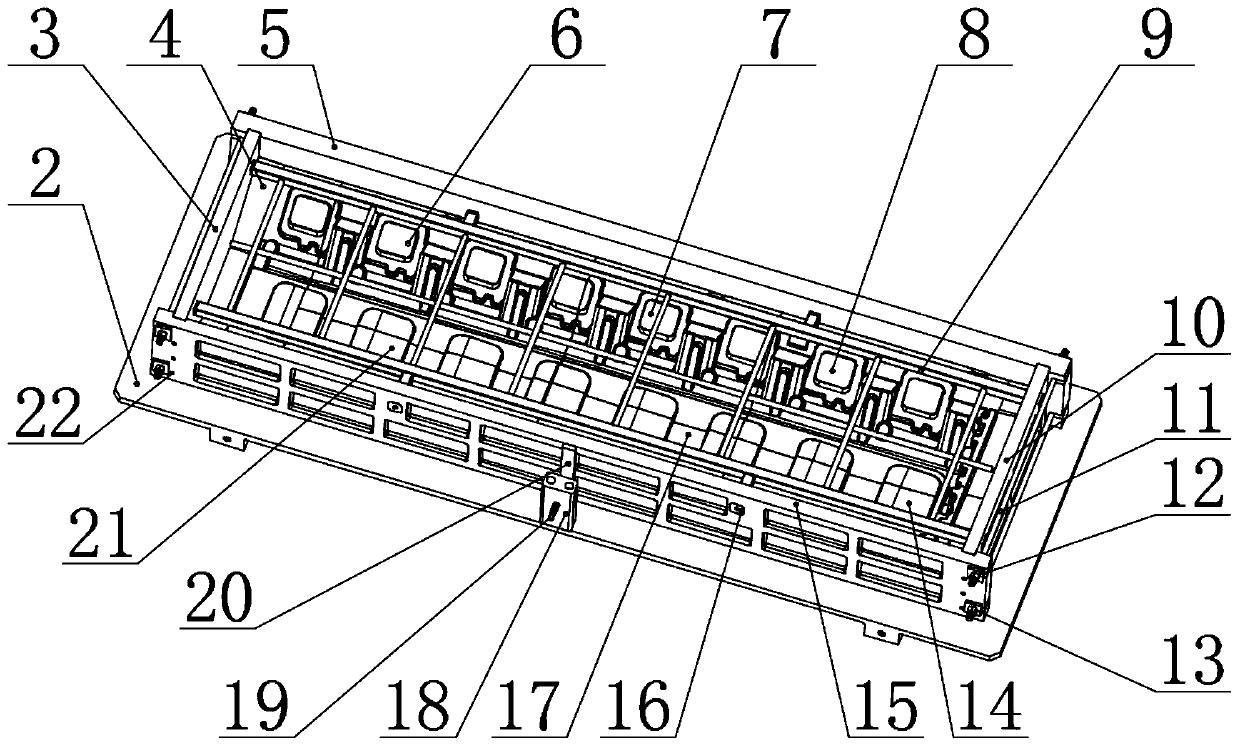

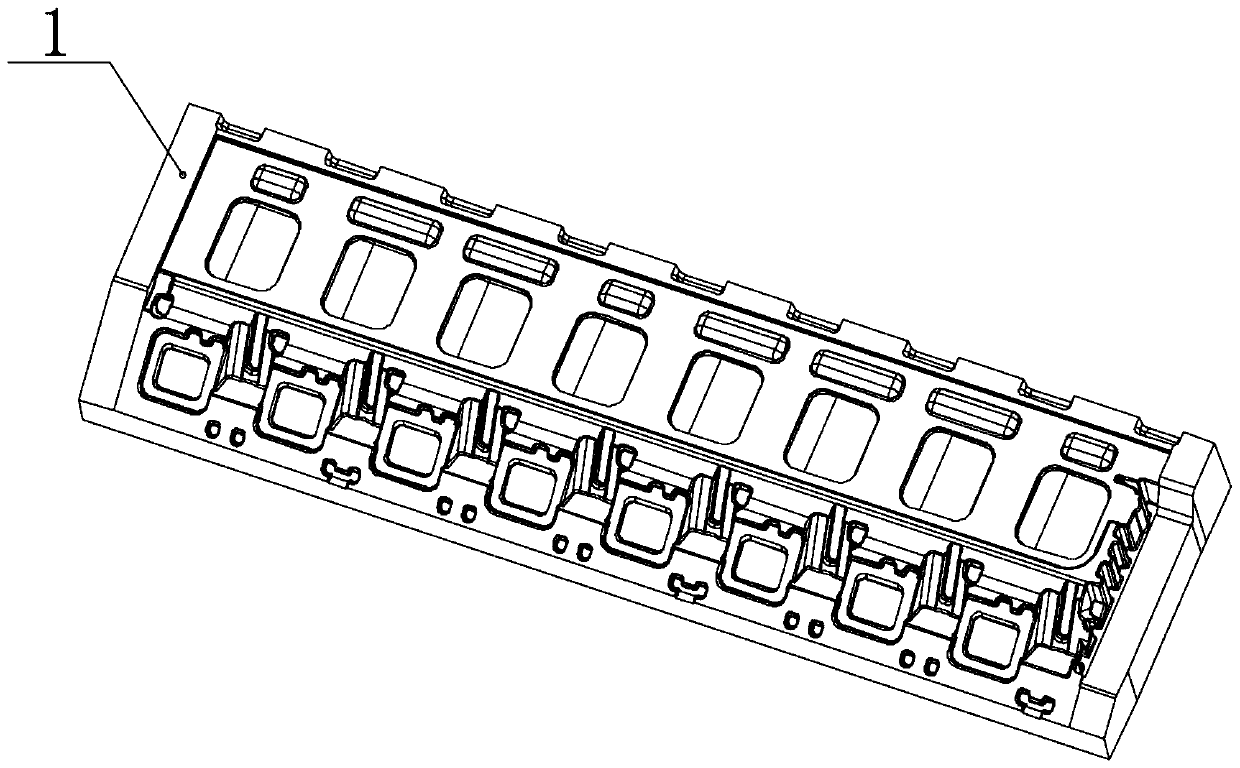

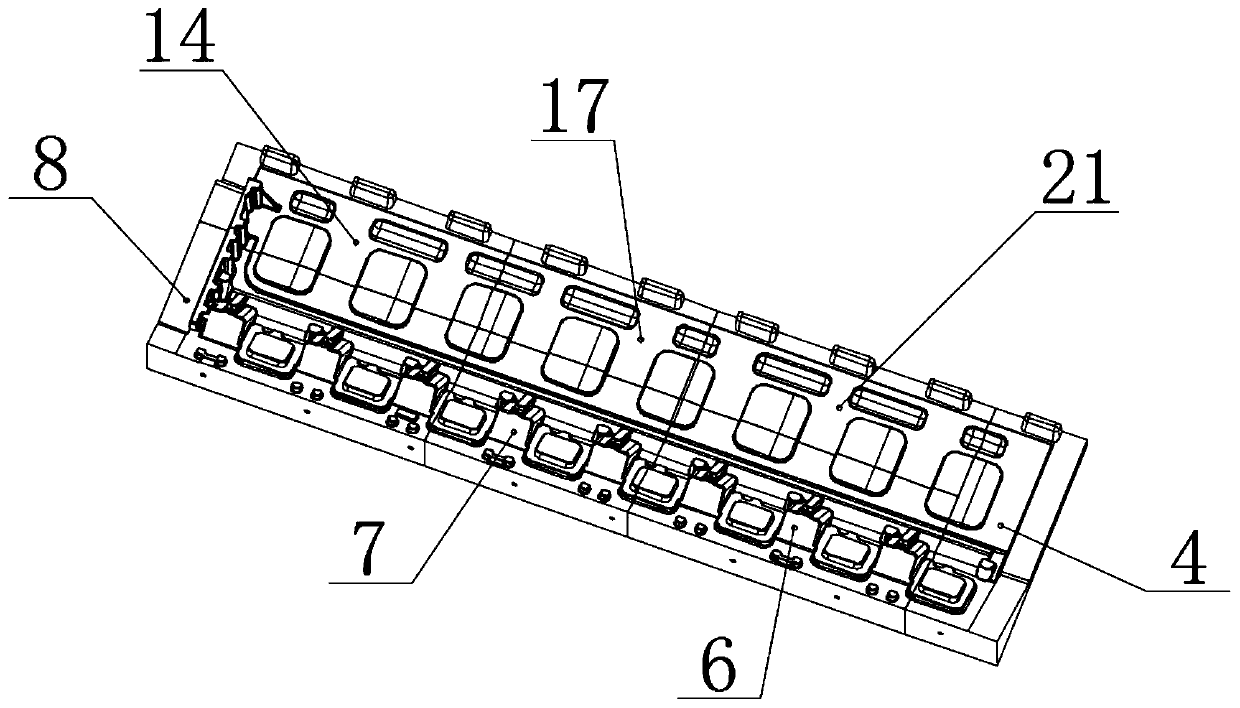

[0037] refer to Figure 1 to Figure 6As shown, a super-large manual core box mold of a V-type engine cylinder block of the present invention includes a bottom mold 2 and a side mold assembly, and the side mold assembly includes a split first side mold 3 and a second side mold 5 , the third side mold 10 and the fourth side mold 15, the second side mold 5 is fixed on the bottom mold 2, the first side mold 3 and the third side mold 10 are snapped on the second side mold 5 and the fourth side mold respectively Between the two sides of 15, both sides of the second side mold 5 and the fourth side mold 15 are provided with a screw clamping groove, through which the locking screw 11 can be clamped, and the two locking screws 11 of each Both ends are locked by washers 12 and n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com