Grease injection head facilitating conductive grease filling of strain clamp

A technology of tension-resistant clamp and conductive grease, which is applied to the device and coating of the surface coating liquid, which can solve the problems of increasing the work intensity of the operator, the inaccurate positioning of the grease injection head, and the waste of conductive grease. Achieve the effect of avoiding mutual sliding, meeting operation requirements and improving injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

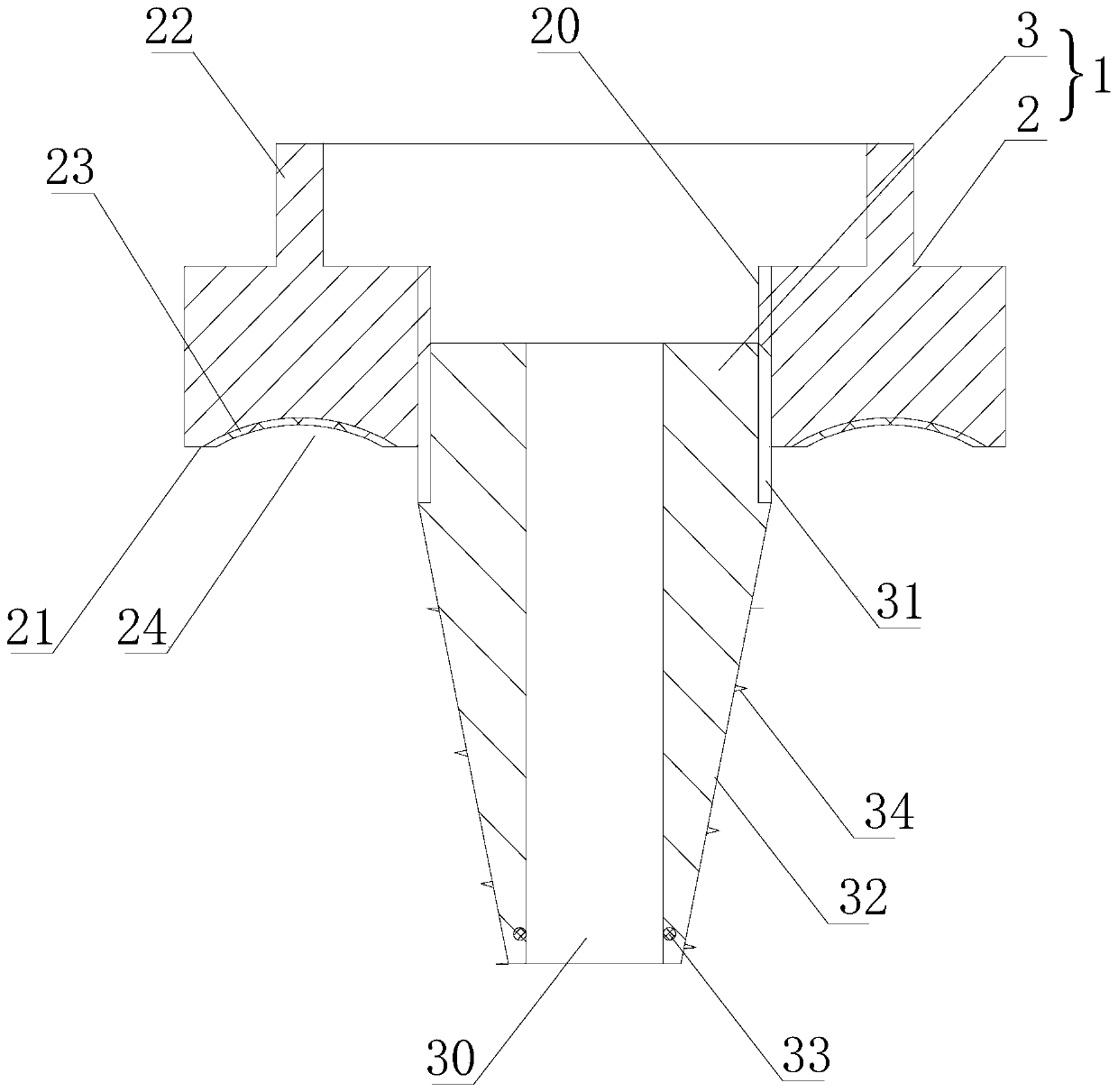

[0018] Such as figure 1 As shown, a grease injection head that is beneficial to filling conductive grease in tension clamps includes a body 1, the body 1 includes an outer sleeve 2 and an inner sleeve 3, and the middle part of the inner sleeve 3 is provided with a grease injection channel 30, so The inner cover 3 includes a connection section 31 connected to the outer cover 2, and a positioning section 32 extending into the tension clamp. The outer cover 2 includes a positioning end surface 21 in contact with the tension clamp, and a section of the main body 1 The fixed head 22 fixed on the grease injection tube, the body 1 is fixed on the tension clamp by means of the positioning section 32 and the positioning end face 21, the conductive grease enters the grease injection channel 30 after passing through the fixed head 22 and is filled to the tension line folder.

[0019] The main body is fixed on the tension clamp through the positioning section and the positioning end face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com