A protective film bonding device for rectangular aluminum profiles

A bonding device and protective film technology, applied in the field of protective film bonding devices, can solve the problems of increasing the burden on the staff, hand fatigue and pain, and low efficiency of film application, so as to improve the efficiency of film application, avoid hand fatigue and pain, and improve the structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

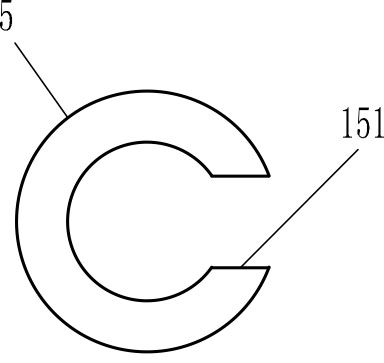

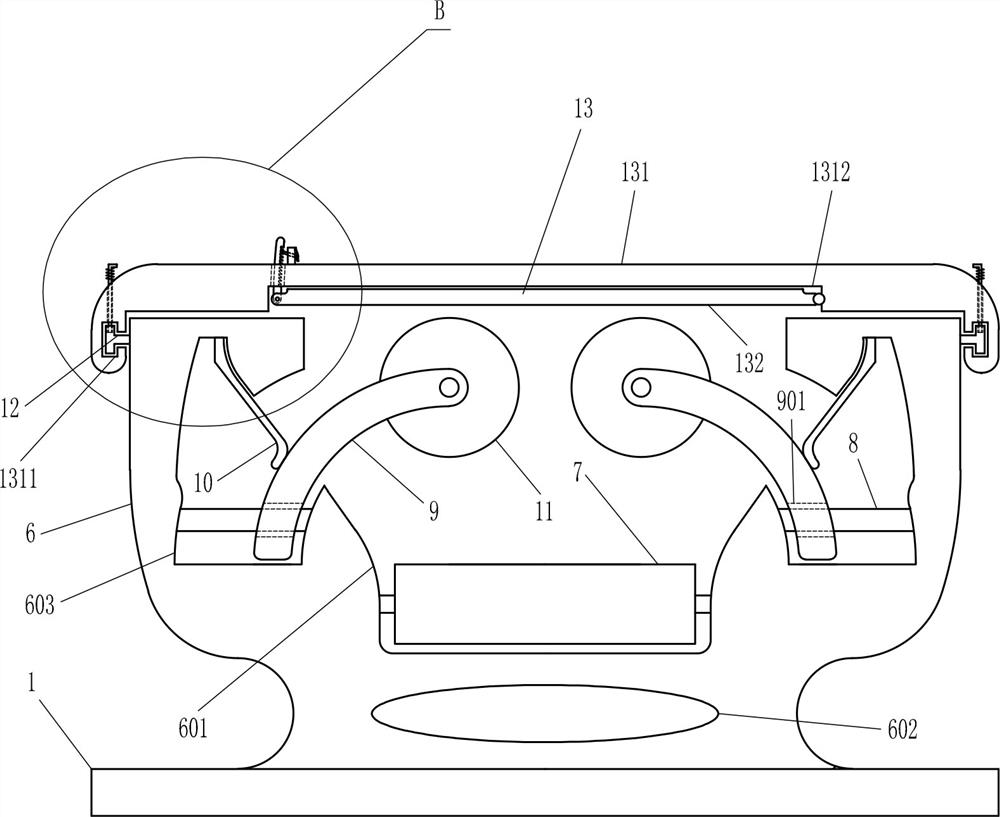

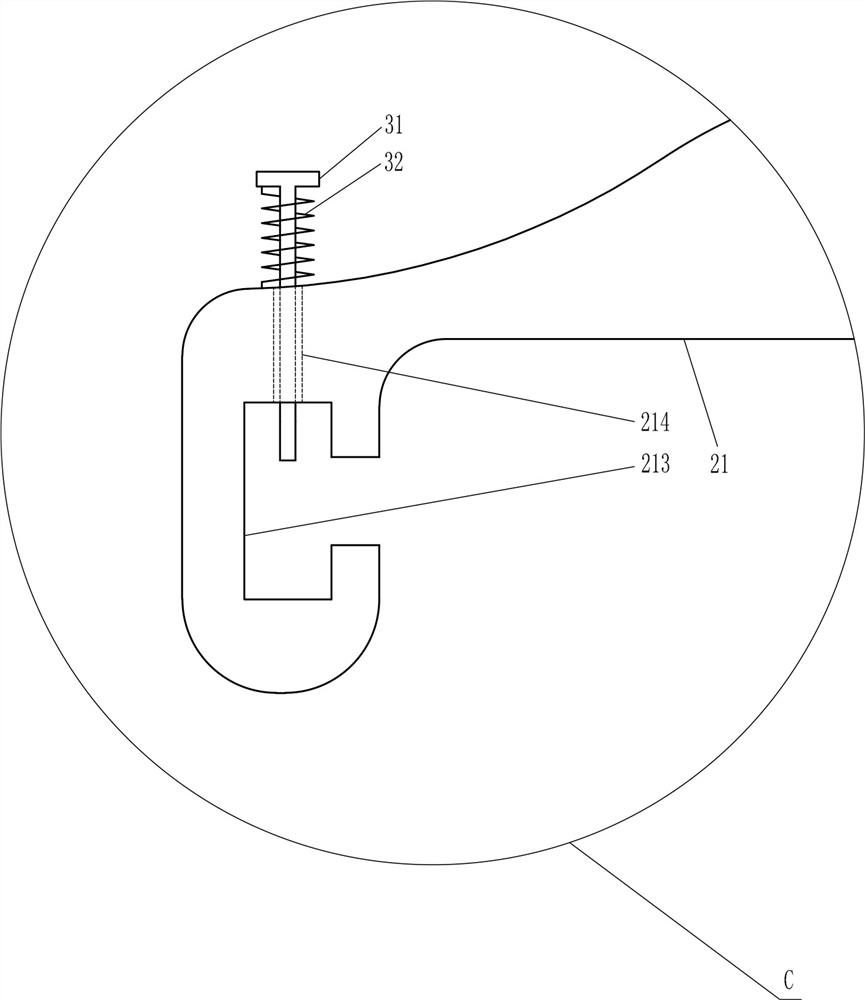

[0021] A protective film laminating device for rectangular aluminum profiles, such as Figure 1-5 As shown, it includes a base 1, a large bracket 2, a connecting shaft 3, a large arc pressure plate 4, a ring 5, a large support plate 6, a large rotating roller 7, a large rectangular guide rod 8, a large arc rod 9, a large plate The spring 10, the large contact wheel 11, the T-rail 12 and the diaphragm traction device 13, the left end of the top of the base 1 is fixed with a large bracket 2 symmetrically front and rear, and the upper end of the large bracket 2 is provided with a large rotating slot 201 running through the front and rear. The left side of the top end of the bracket 2 is provided with a large arc-shaped groove 202 extending to the right, the large arc-shaped groove 202 is communicated with the large rotating groove 201, and the left side of the large bracket 2 is symmetrically opened with an arc-shaped guide hole 203 running through the front and rear. , the arc-s...

Embodiment 2

[0023] A protective film laminating device for rectangular aluminum profiles, such as Figure 1-5 As shown, it includes a base 1, a large bracket 2, a connecting shaft 3, a large arc pressure plate 4, a ring 5, a large support plate 6, a large rotating roller 7, a large rectangular guide rod 8, a large arc rod 9, a large plate The spring 10, the large contact wheel 11, the T-rail 12 and the diaphragm traction device 13, the left end of the top of the base 1 is fixed with a large bracket 2 symmetrically front and rear, and the upper end of the large bracket 2 is provided with a large rotating slot 201 running through the front and rear. The left side of the top end of the bracket 2 is provided with a large arc-shaped groove 202 extending to the right, the large arc-shaped groove 202 is communicated with the large rotating groove 201, and the left side of the large bracket 2 is symmetrically opened with an arc-shaped guide hole 203 running through the front and rear. , the arc-s...

Embodiment 3

[0026] A protective film laminating device for rectangular aluminum profiles, such as Figure 1-7As shown, it includes a base 1, a large bracket 2, a connecting shaft 3, a large arc pressure plate 4, a ring 5, a large support plate 6, a large rotating roller 7, a large rectangular guide rod 8, a large arc rod 9, a large plate The spring 10, the large contact wheel 11, the T-rail 12 and the diaphragm traction device 13, the left end of the top of the base 1 is fixed with a large bracket 2 symmetrically front and rear, and the upper end of the large bracket 2 is provided with a large rotating slot 201 running through the front and rear. The left side of the top end of the bracket 2 is provided with a large arc-shaped groove 202 extending to the right, the large arc-shaped groove 202 is communicated with the large rotating groove 201, and the left side of the large bracket 2 is symmetrically opened with an arc-shaped guide hole 203 running through the front and rear. , the arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com