A kind of chlorinated aromatic compound (r 1 -x m ) dechlorination method

A technology for aromatic compounds and copper catalysts is applied in the field of dechlorination of chlorinated aromatic compounds, which can solve the problems of reducing the added value of products and increasing treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

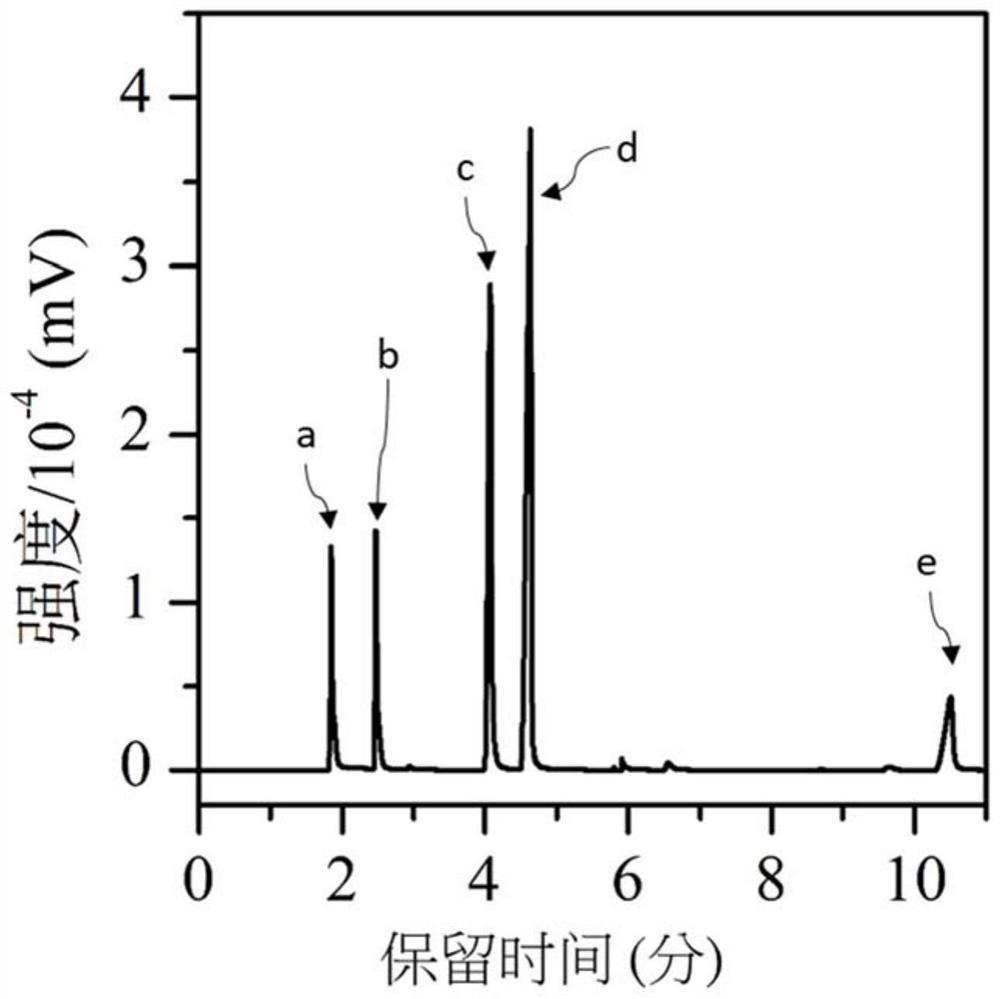

[0047] According to the dechlorination kit and method provided by the present invention, in 100mL polytetrafluoroethylene lining, add 10mL methanol, 0.9073g 1,2,3-trichlorobenzene as a substrate, 292mg Cu catalyst, 0.8g NaOH to get mixture. The mixture was stirred evenly, placed in a high-pressure reactor, and hydrogenated at 130° C. for 80 minutes. After the reaction, the reaction product was analyzed by gas chromatography, such as figure 1 As shown, the peaks a, b, c, d, and e from left to right in the figure represent benzene, chlorobenzene, m-dichlorobenzene, o-dichlorobenzene, and 1,2,3-trichlorobenzene respectively. The conversion rate of 1,2,3-trichlorobenzene is 90%, and the selectivity of dichlorobenzene is 88%. The reaction result shows that the dechlorination kit provided by the present invention has high selectivity.

Embodiment 2

[0049] According to the dechlorination kit and method provided by the present invention, in a 100-mL polytetrafluoroethylene liner, add 10mL methanol, 0.9073g 1,2,3-trichlorobenzene as a substrate, 292mg Cu catalyst, 0.8g NaOH mixture. The mixture was stirred evenly, placed in a high-pressure reactor, and hydrogenated at 180° C. for 30 minutes. After the reaction, the reaction product was analyzed by gas chromatography. As a result, the conversion rate of 1,2,3-trichlorobenzene was 100%, and the selectivity of dichlorobenzene was 79%.

Embodiment 3

[0051] According to the dechlorination kit and method provided by the present invention, in a 100-mL polytetrafluoroethylene liner, add 10mL methanol, 0.9073g 1,2,3-trichlorobenzene as a substrate, 292mg Cu catalyst, 1.12g KOH mixture. The mixture was stirred evenly, placed in a high-pressure reactor, and hydrogenated at 130° C. for 60 minutes. After the reaction, the reaction product was analyzed by gas chromatography. As a result, the conversion rate of 1,2,3-trichlorobenzene was 93%, and the selectivity of dichlorobenzene was 89%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com