Box opening device

A packaging box and component technology, which is applied in the field of box opening devices, can solve the problems of easy inversion, high labor intensity, and low opening efficiency of packaging boxes, so as to reduce the phenomenon of bottle inversion, reduce manual participation, and improve demolition. Effects of Packet Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

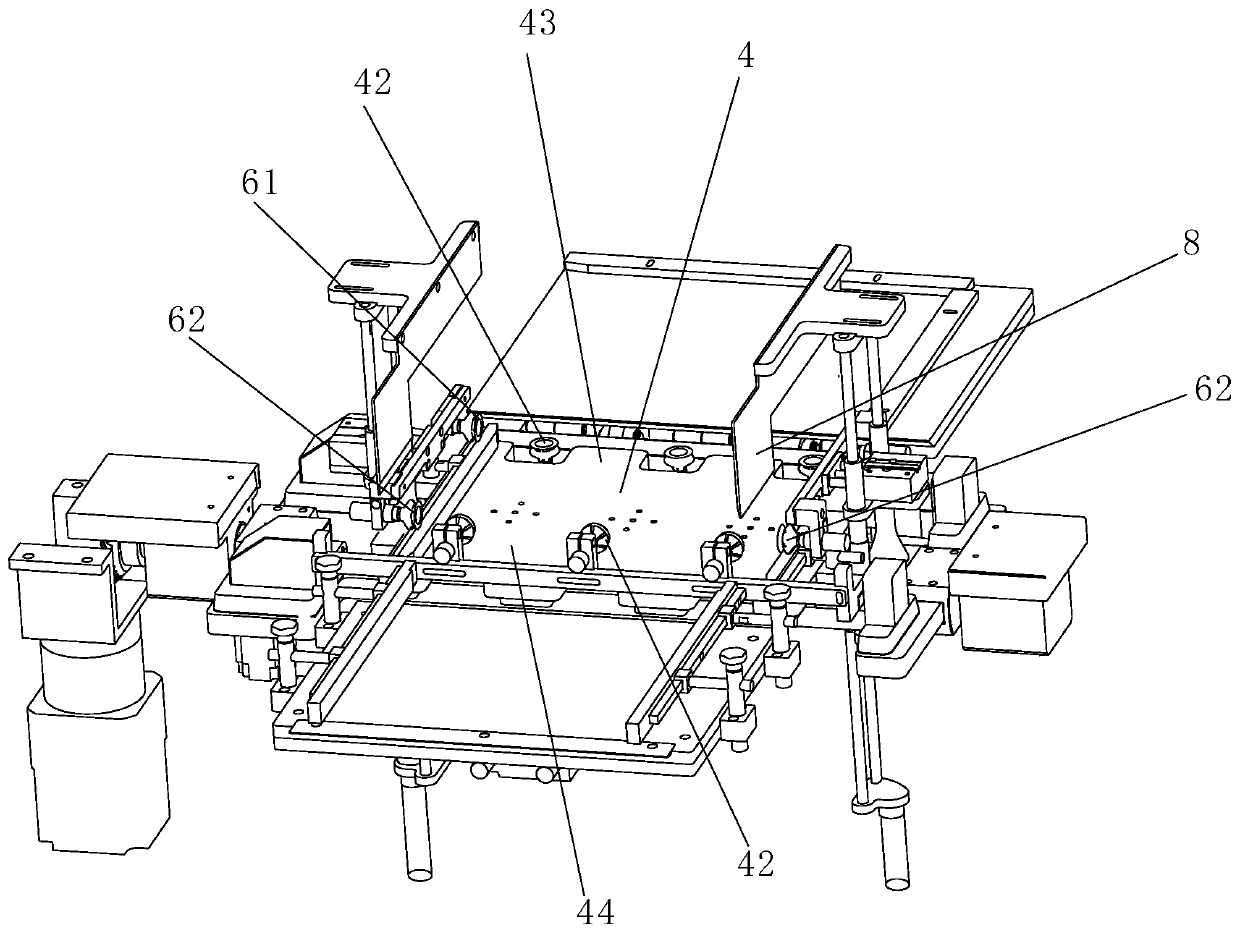

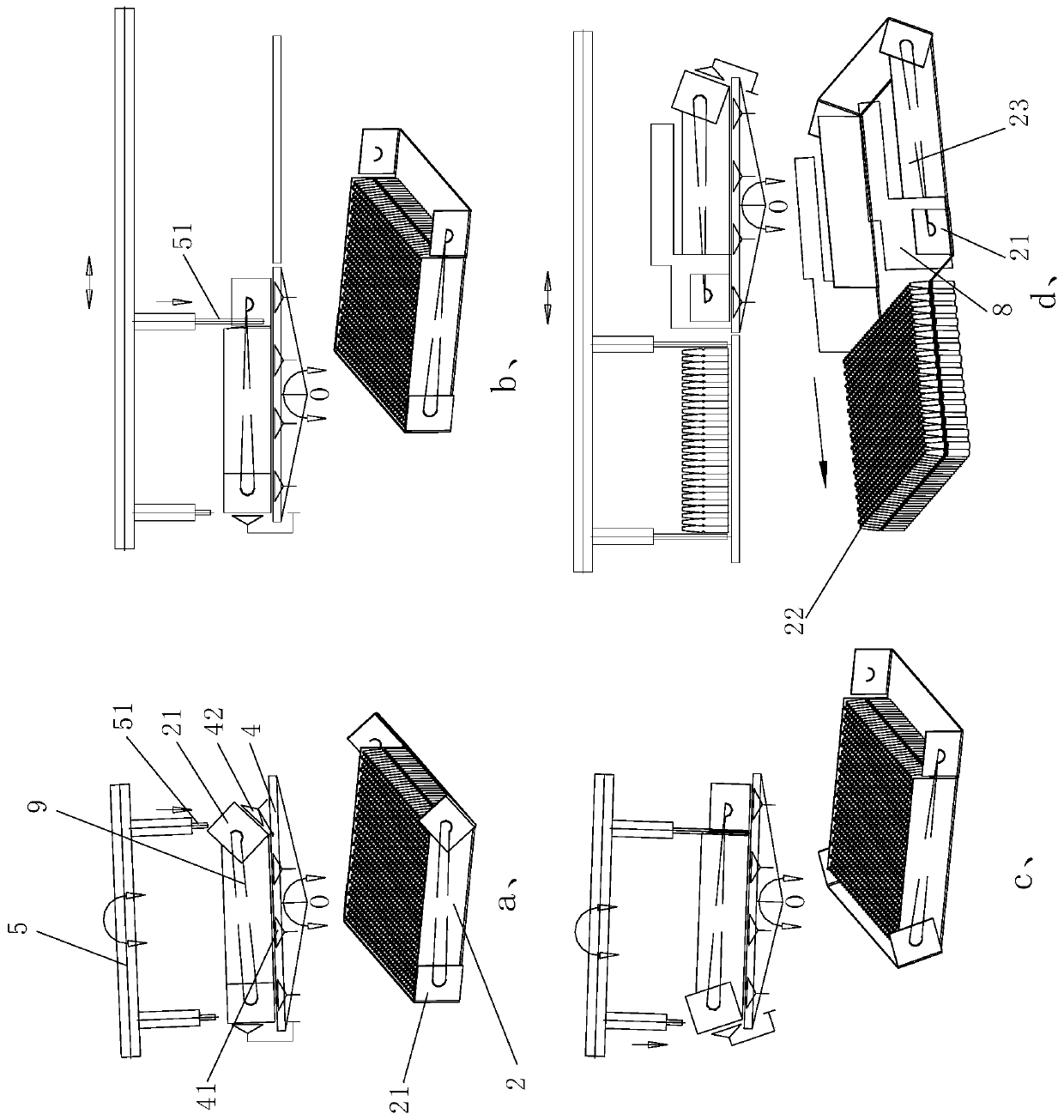

[0018] Figure 1 to Figure 2 Shown is a kind of embodiment of unpacking device of the present invention, and the unpacking device of present embodiment comprises rotating platform 4 and is arranged on the bottle pushing part 5 above rotating platform 4, and the bottle-in end 43 of rotating platform 4 and bottle-out Both ends 44 are provided with opening and hinge parts 42, both sides of the bottle outlet end 44 are provided with reciprocating guide plates 8, and the bottle pushing part 5 is provided with a lifting bottle protection plate above the bottle inlet end 43 and the bottle outlet end 44. 51. Wherein, the opening hinge part 42 can be, for example, a suction cup, a gripper, etc., and the bottle pushing part 5 can be, for example, a push rod or the like.

[0019] This unpacking device, during work earlier packing box 2 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com