Flexible rod piece storing and positioning frame

A positioning frame and flexible technology, applied in the direction of tool storage devices, manufacturing tools, etc., can solve the problem of no flexible tooling, etc., and achieve the effect of being accurate and easy to grab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

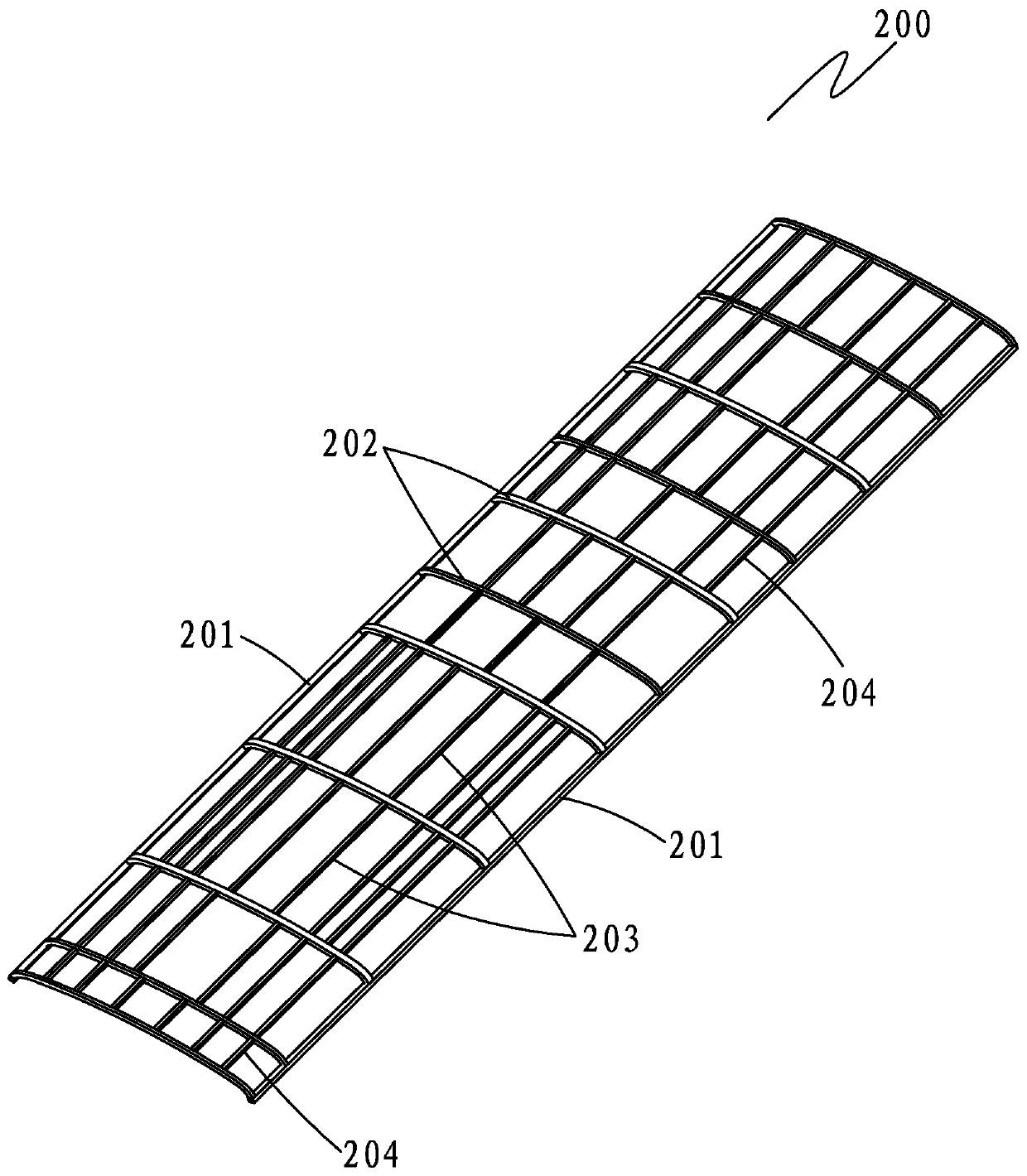

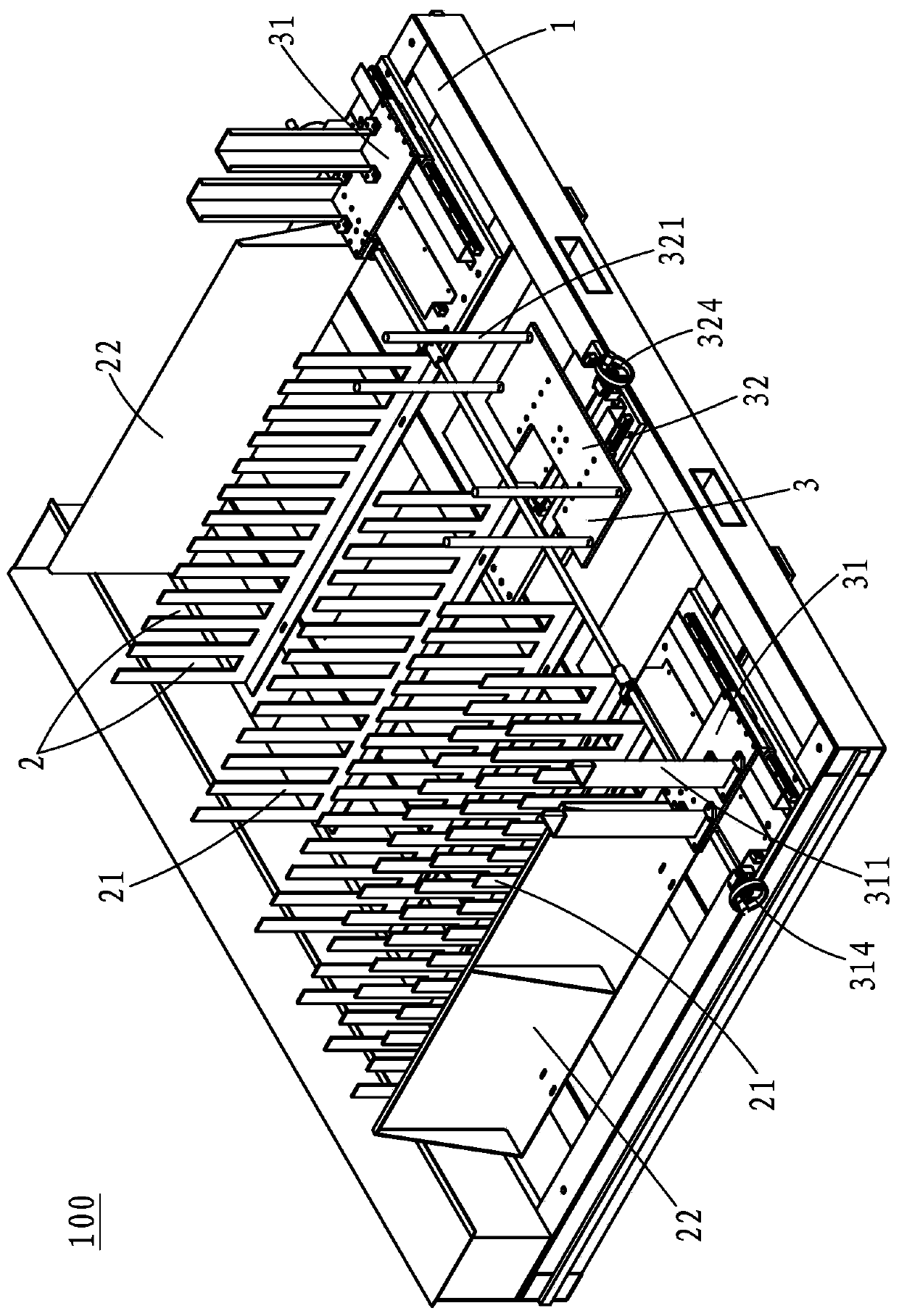

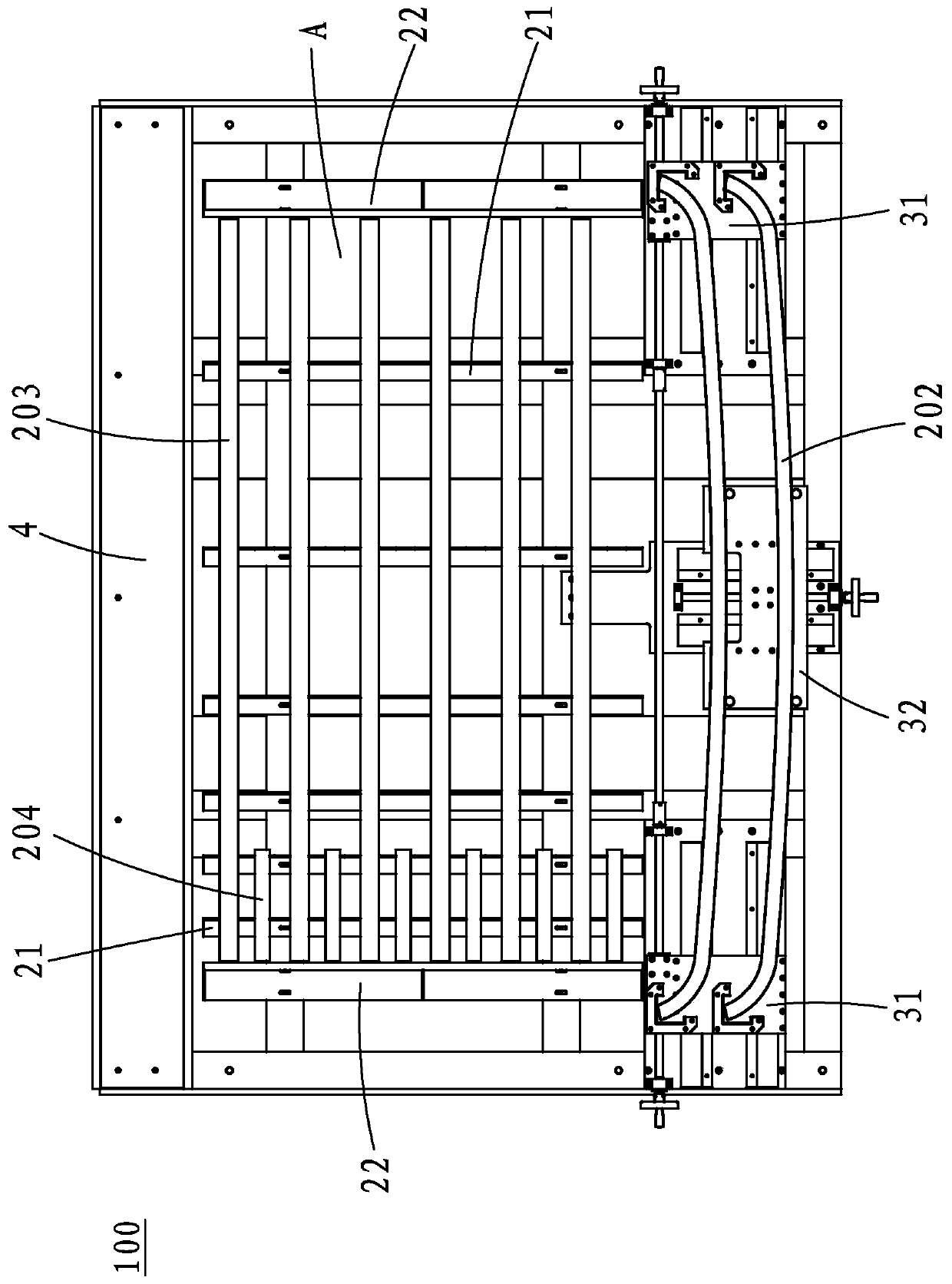

[0020] see Figure 2 to Figure 5 As shown, a preferred embodiment of the rod flexible storage positioning frame 100 of the present invention includes a bottom plate 1, a plurality of straight rod slots 2, and a plurality of arc rod slots 3, and also includes a defective part placement slot 4, The bottom plate 1 does not necessarily need to be a whole board, but can be formed by connecting several criss-cross strip plates. The plurality of arc rod grooves 3 are located on one side of the plurality of straight rod grooves 2; 4 is located on the other side of the plurality of straight rod grooves 2.

[0021] The straight bar slot 2 is composed of a plurality of toothed vertical plates 21 fixedly connected to the base plate and two fixed vertical plates 22, and the plurality of toothed vertical plates 21 are located between the two fixed vertical plates 22 , and the spacing is not equal, such as figure 2 As shown in , the spacing of the toothed vertical plate 21 at the left end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com