Node with buckling-restrained braced connecting plate penetrating through beam column and manufacturing method thereof

A buckling constraint, beam-column joint technology, applied in building components, earthquake resistance, building types, etc., can solve problems such as cumbersome operations, complex force transmission between buckling constraint support and steel beam-column, and inability to ensure the integrity of joint connection, and achieve simple force transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

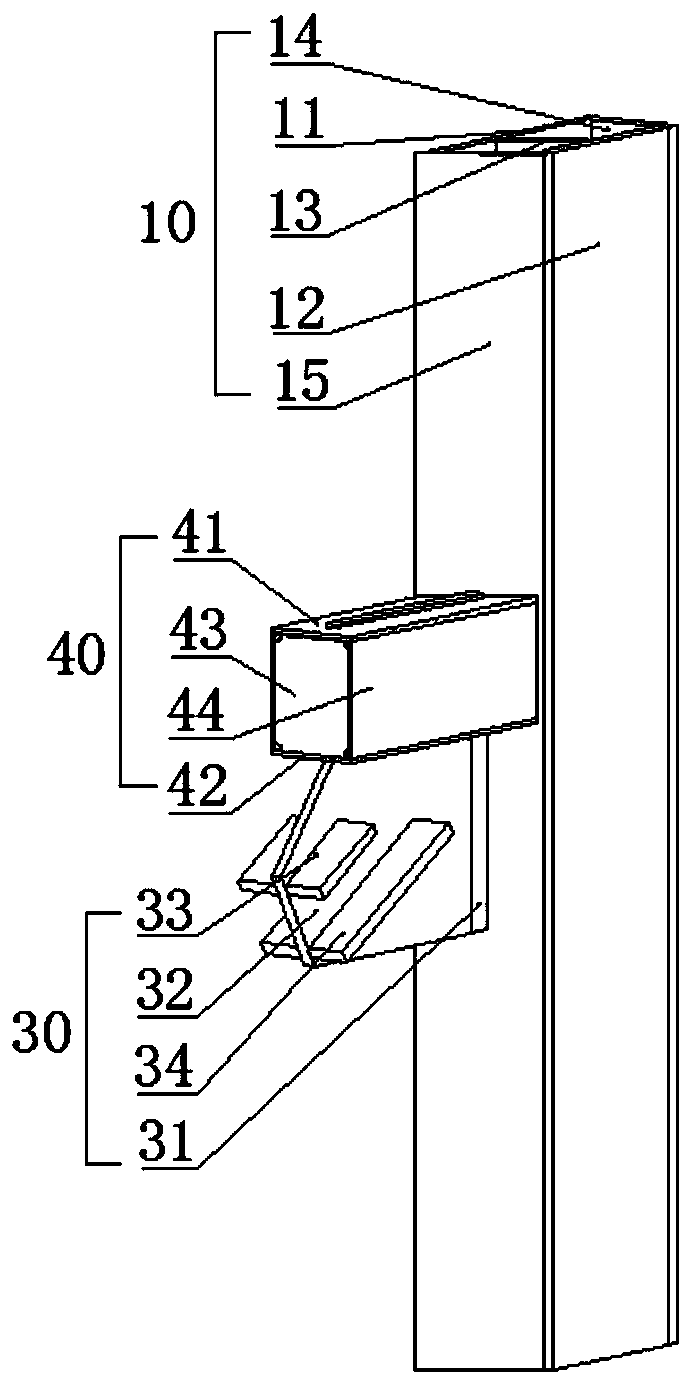

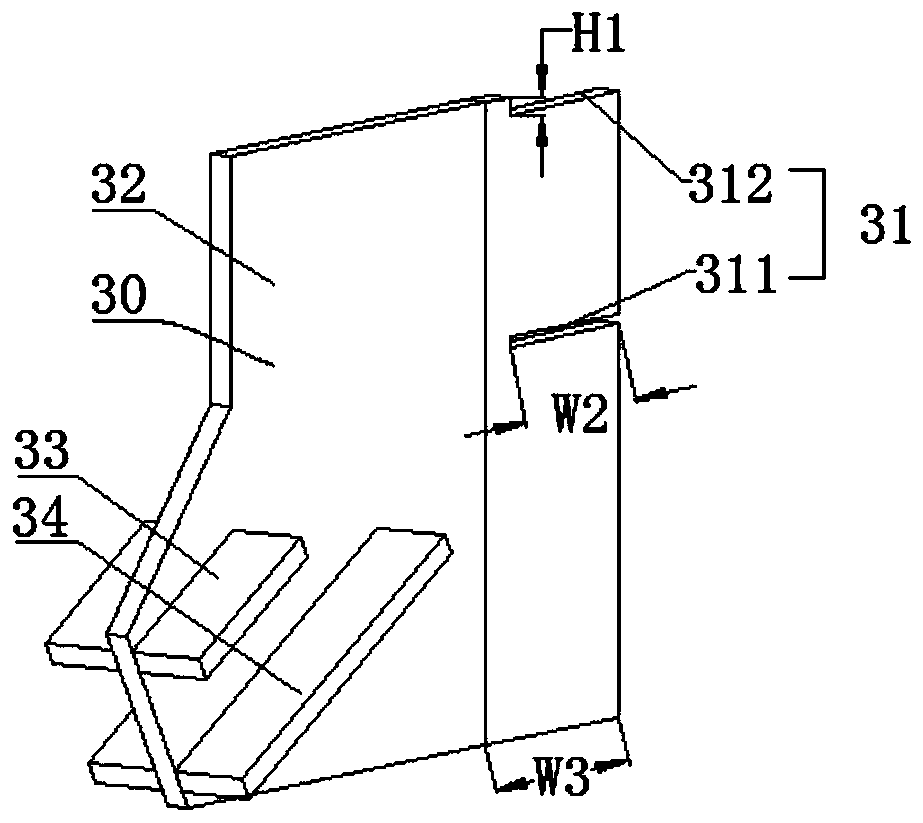

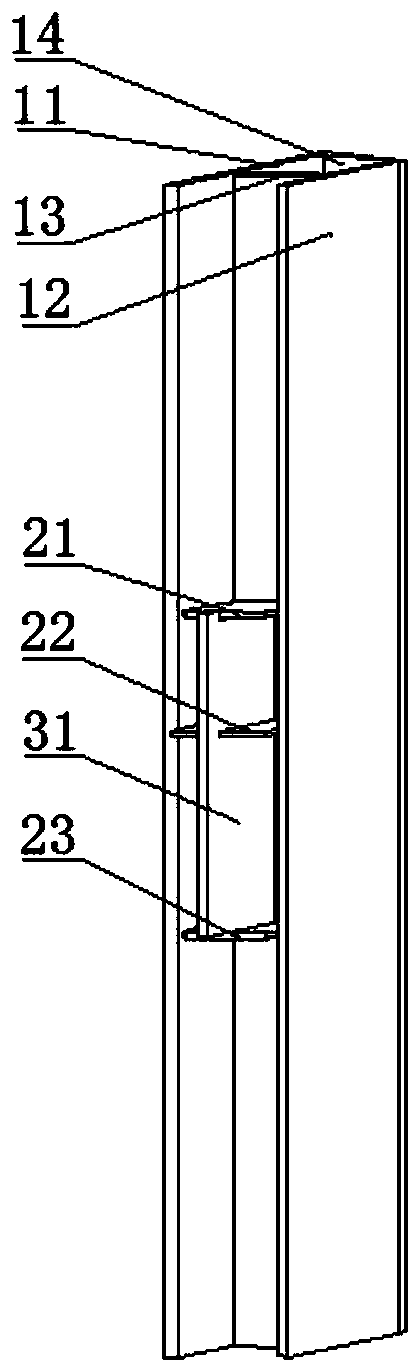

[0038] A buckling-restrained bracing connecting plate penetrates the beam-to-column joint, such as Figure 1-6 As shown, it includes a Japanese-shaped steel column 10 , an internal stiffening structure 20 of the steel column, a buckling-constrained bracing connection structure 30 and a box-shaped beam 40 . Among them, the internal stiffening structure 20 of the steel column is embedded in the inside of the Japanese-shaped steel column 10 and is arranged perpendicular to the Japanese-shaped steel column 10; The interior of the shaped steel column 10 is fixedly connected to the internal stiffening structure 20 of the steel column; the box beam 40 is placed outside the Japanese-shaped steel column 10 and runs through the upper end of the buckling-constrained support connection structure 30 to be connected and fixed to the outer wall of the Japanese-shaped steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com