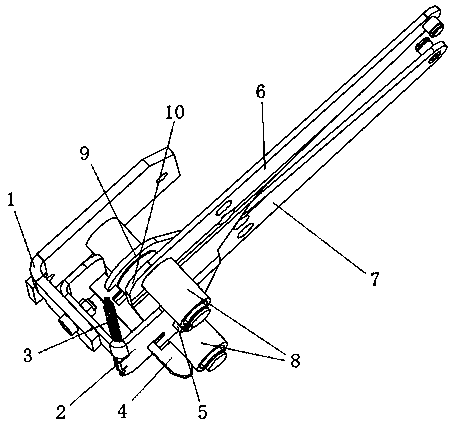

Switch cabinet and valve driving mechanism with self-locking function thereof

A driving mechanism and valve technology, applied in the direction of pull-out switch cabinets, switch devices, electrical components, etc., can solve problems such as electric shock safety accidents, and achieve the effect of short displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

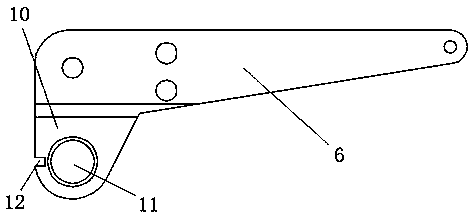

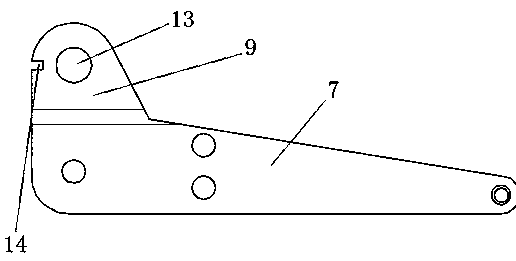

Examples

Embodiment 2

[0031] The second embodiment of a switchgear of the present invention differs from the first embodiment in that the end of the deadbolt that cooperates with the unlocking push rod may not be an arc structure, and may also be set as a wedge structure. At this time, the end of the push rod The middle plate is also provided with a matching wedge surface structure.

Embodiment 3

[0032] The third embodiment of a switchgear of the present invention differs from the first embodiment in that the number of spring connection holes on the bolt can also be adjusted according to actual needs, for example, one or three.

[0033] The fourth embodiment of a switchgear of the present invention differs from the first embodiment in that there may be only one connecting plate, and at this time there is only one valve and it is connected to the connecting plate, and at this time there is only one The tongue groove is enough.

Embodiment 5

[0034] The fifth embodiment of a switchgear of the present invention is different from the first embodiment in that the pushing part of the middle plate and the pushing part of the side plate can also be formed by correspondingly welded cylinders or round tubes.

[0035] Embodiment 6 of a switchgear of the present invention is different from Embodiment 1 in that the structure of the lock tongue is different. The lock tongue includes a push arm and a lock arm, and the length of the push arm is greater than the length of the lock arm. When the unlocking push rod and the push arm push, the locking arm can be driven to separate from the draw-in groove, and at this moment, no groove is arranged on the dead bolt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com