Inertia/visual integrated attitude determination device and method for rocker arm of coal mining machine

A shearer and vision technology is applied in the field of the inertial/visual combined attitude determination device of the shearer rocker arm, and can solve the problems of difficulty in obtaining the absolute attitude of automatic control, decreased reliability of equipment operation, incomplete attitude information, and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

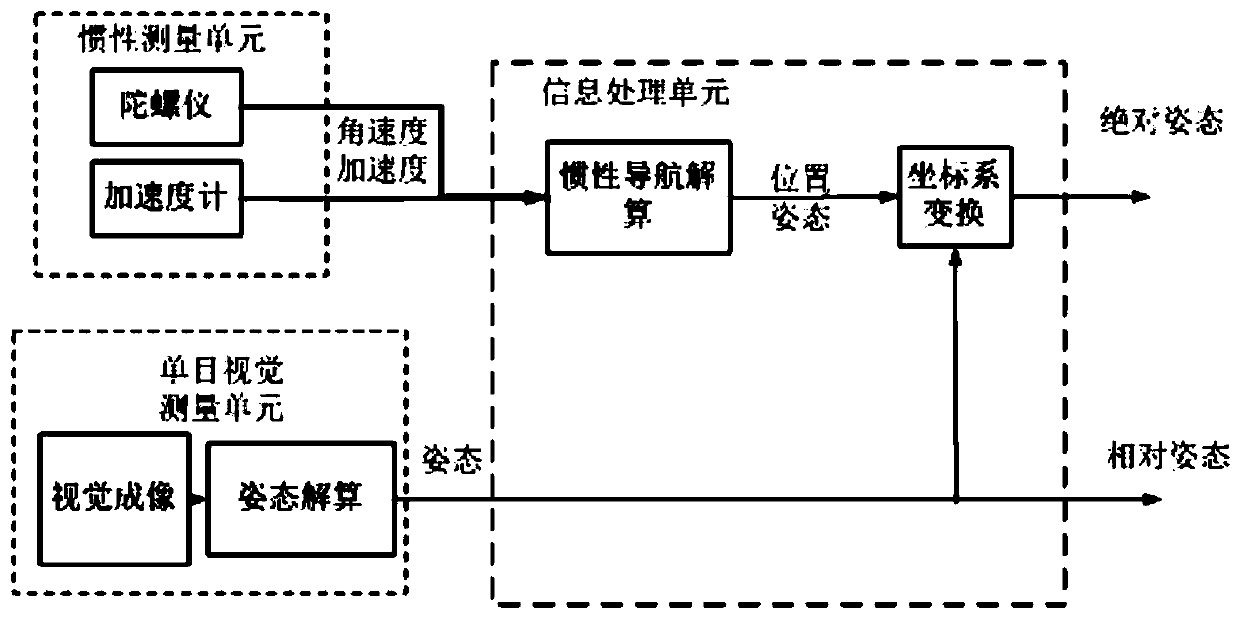

[0100] Example 1: Such as figure 1 As shown, the shearer rocker arm inertial / visual combined attitude determination device includes a target feature point unit 1, a monocular vision measurement unit 2, an inertial measurement unit 3, and an information processing unit 4. The target feature point unit 1 is installed on the rocker arm of the shearer, and consists of 4 optical feature points, which are coplanar and square, such as Figure 4 As shown; the inertial measurement unit 3 and the monocular vision measurement unit 2 are rigidly connected and are installed on the shearer body to ensure that all optical feature points are within the field of view; the information processing unit 4 is installed in the electrical control box of the shearer , Complete the information collection and processing of the monocular vision measurement unit 2 and the inertial measurement unit 3.

[0101] Such as image 3 As shown, the shearer rocker inertial / visual combined attitude determination metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com