Deep-well pump transmission shaft system

A transmission shaft and deep well pump technology, applied in the direction of pumps, pump control, pump devices, etc., can solve the problems of limited transmission distance and inability to meet the long-distance power transmission of product oil tankers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

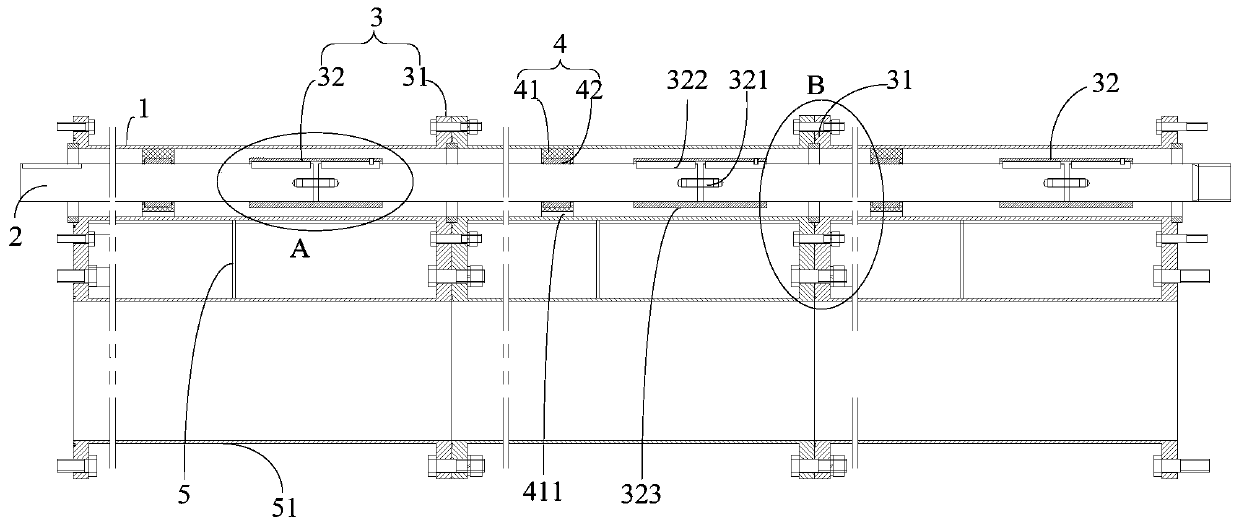

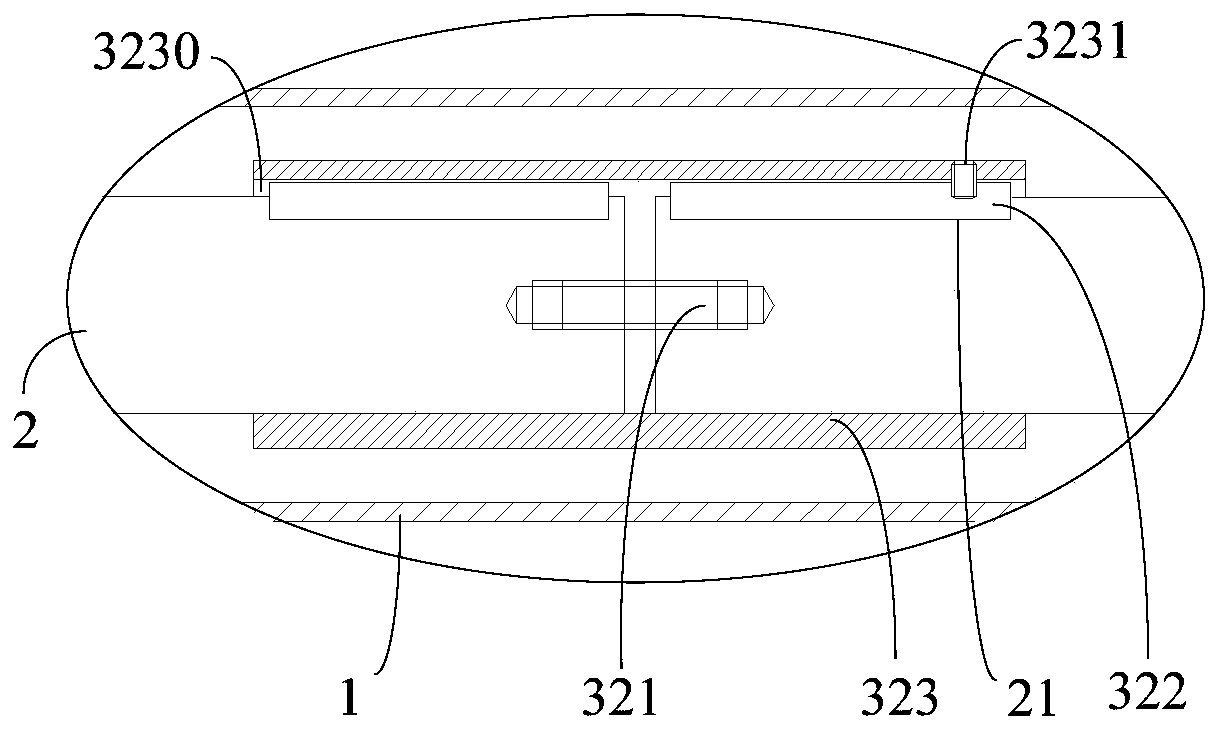

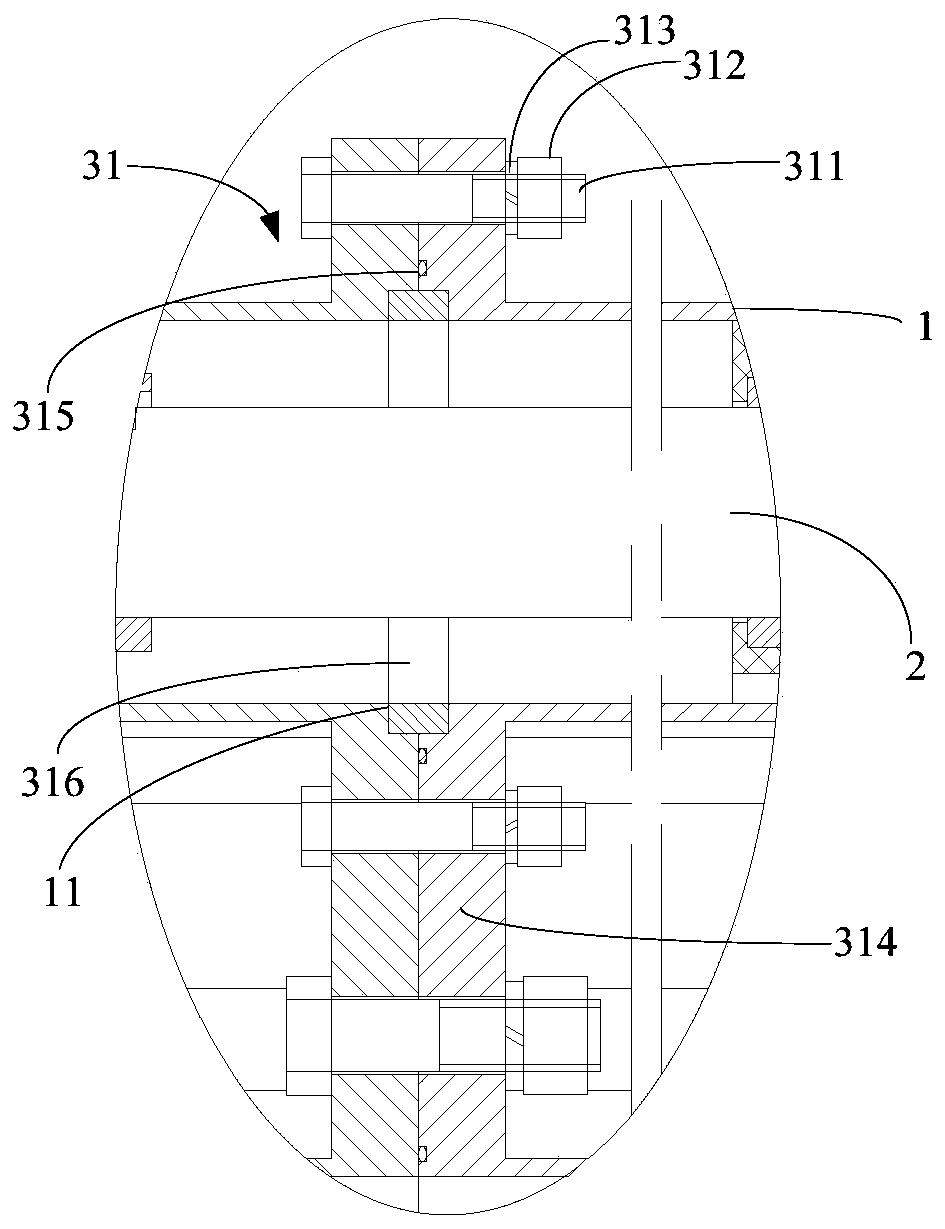

[0026] The embodiment of the present invention provides a deep well pump drive shaft system, such as figure 1 As shown, the transmission shaft system of the deep well pump includes a pipe string 1, a transmission shaft 2, and a connecting mechanism 3. The transmission shaft 2 is installed inside the pipe string 1, and the connecting mechanism 3 includes a first connecting assembly 31 and a second connecting assembly 32. A connection assembly 31 is used to connect the end surfaces of two adjacent pipe strings 1 together, and a second connection assembly 32 is used to connect the end surfaces of two adjacent transmission shafts 2 together. The second connection assembly 32 includes a mounting part 321 , the clamping piece 322 and the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com