Milk powder box

A milk powder box and milk powder technology, applied in the direction of powder material distribution, etc., can solve the problems of complicated steps, inconvenience, milk powder falling, etc., and achieve the effect of simple and ingenious structure design, simplified user operation, and easy disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

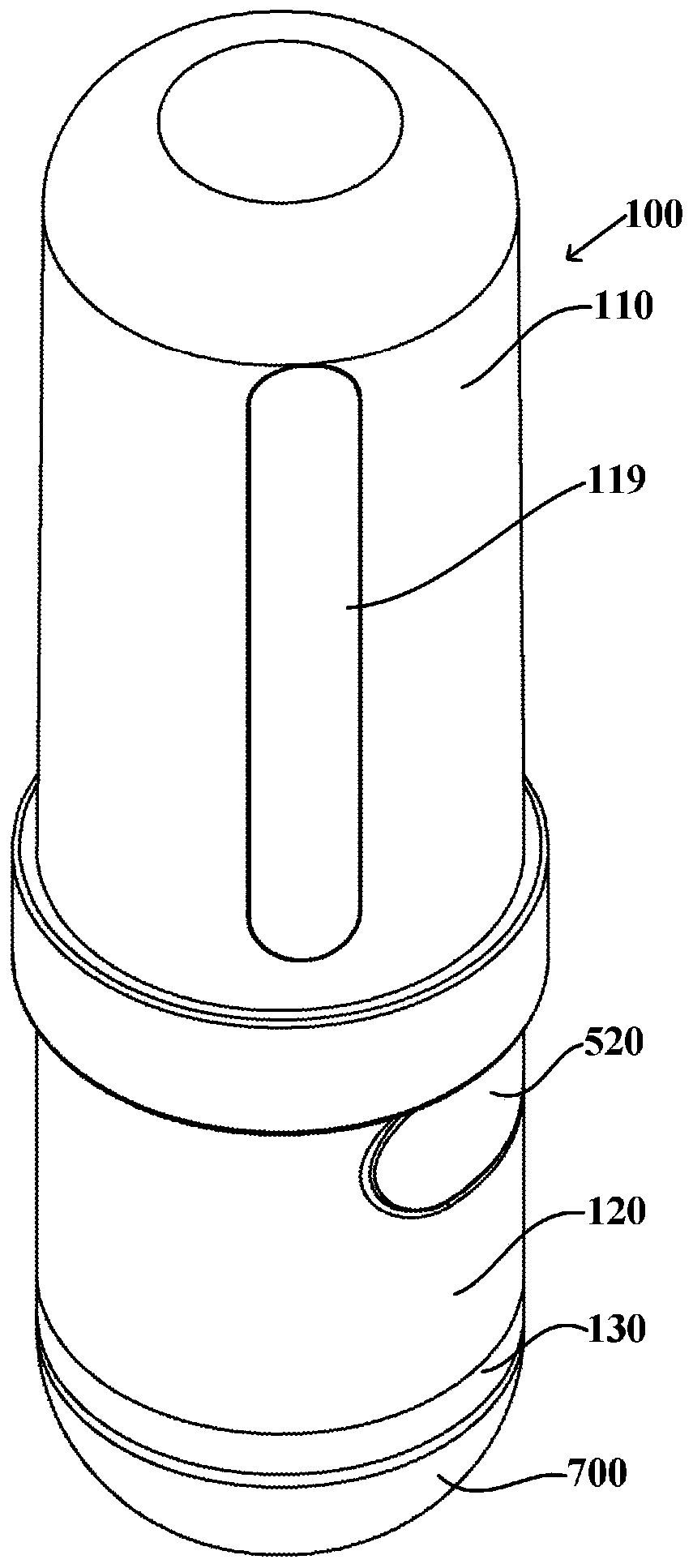

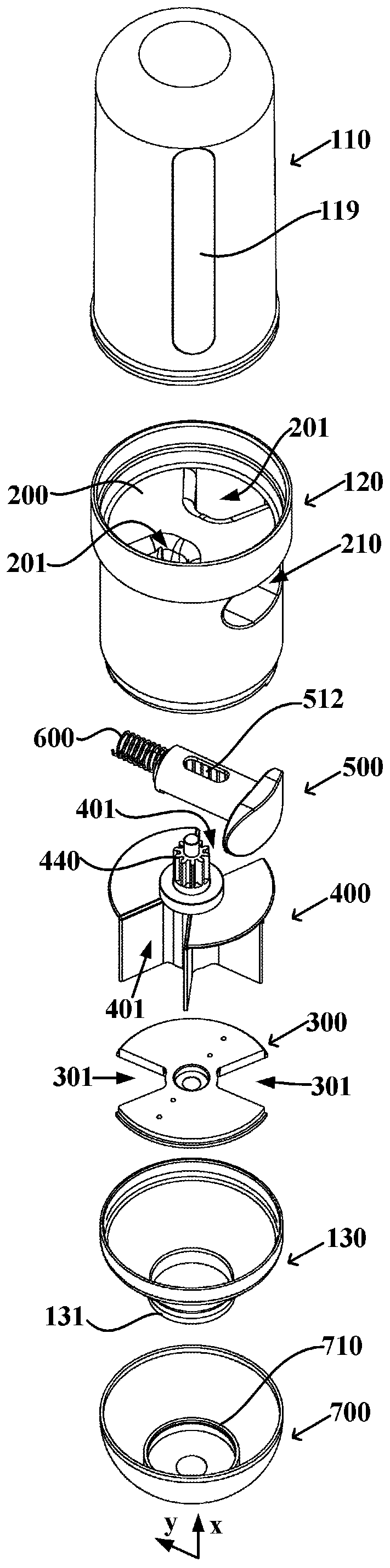

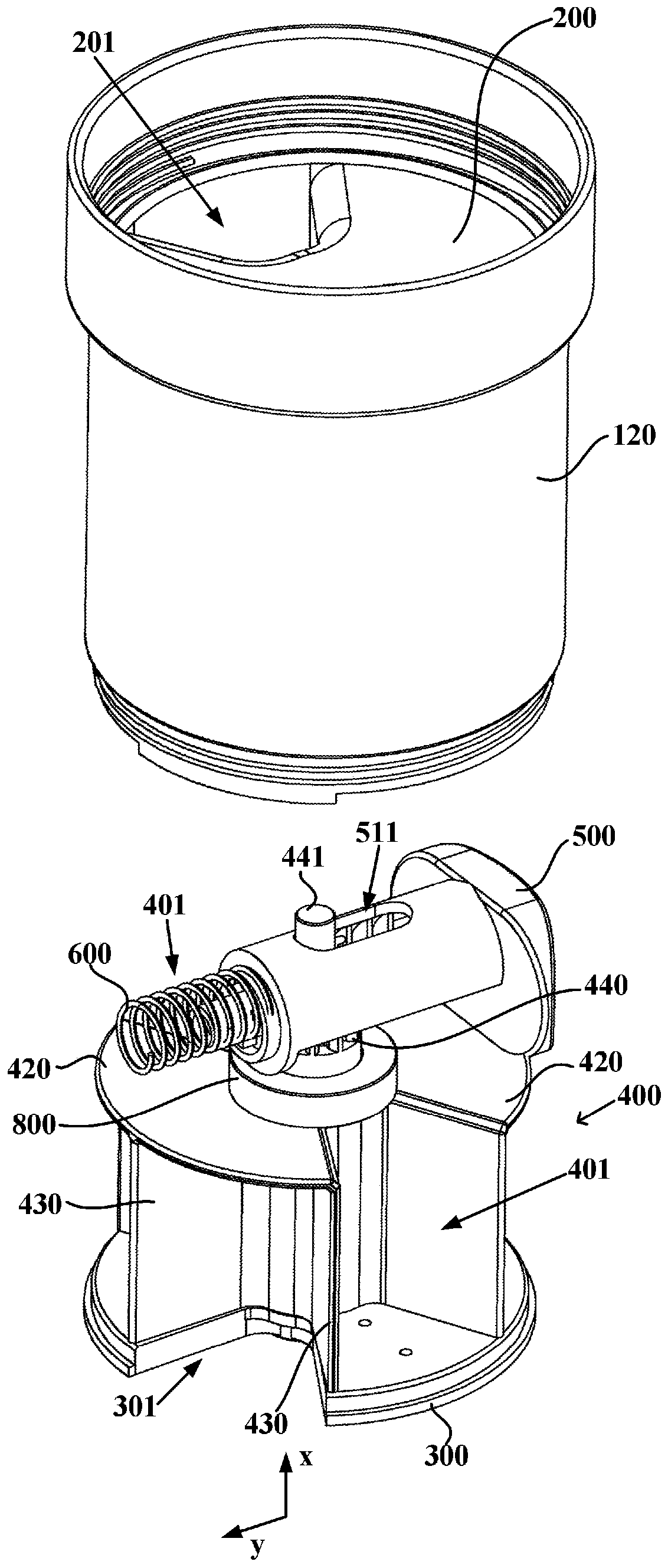

[0035] figure 1 It is a structural schematic diagram of a milk powder box according to an embodiment of the present invention; figure 2 yes figure 1 The disassembled diagram of the milk powder box shown; image 3 yes figure 2 A schematic diagram of the state of the second cylinder 120, the rotating part 400 and the operating part 500 in the shown milk powder box when the rotating part 400 is at the feeding angle; Figure 4 yes image 3 The state schematic diagram of the structure shown when the rotating part 400 is at the discharge angle.

[0036] Such as Figure 1 to Figure 4 As shown, the milk powder box of the embodiment of the present invention may generally include an outer cylinder 100 , a first partition 200 , a second partition 300 and a rotating part 400 .

[0037] The outer cylinder 100 has an accommodating space for accommodating milk powder. Parents can transfer the milk powder of the original milk powder tank to the outer cylinder 100 in advance. One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com