Continuous variable-curvature profile steel straightening machine

A straightening machine and variable curvature technology, which is applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve the problems of accelerated wear of straightening rollers, large equipment, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

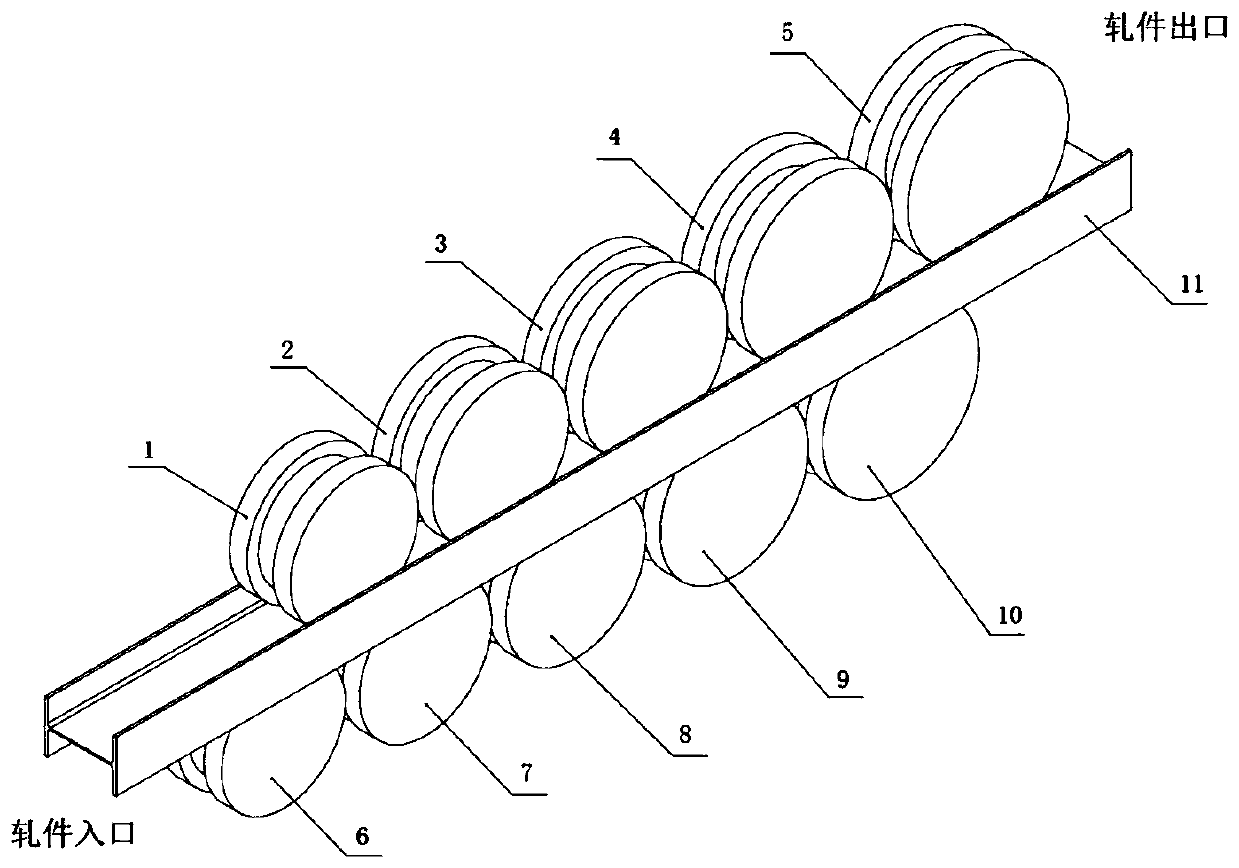

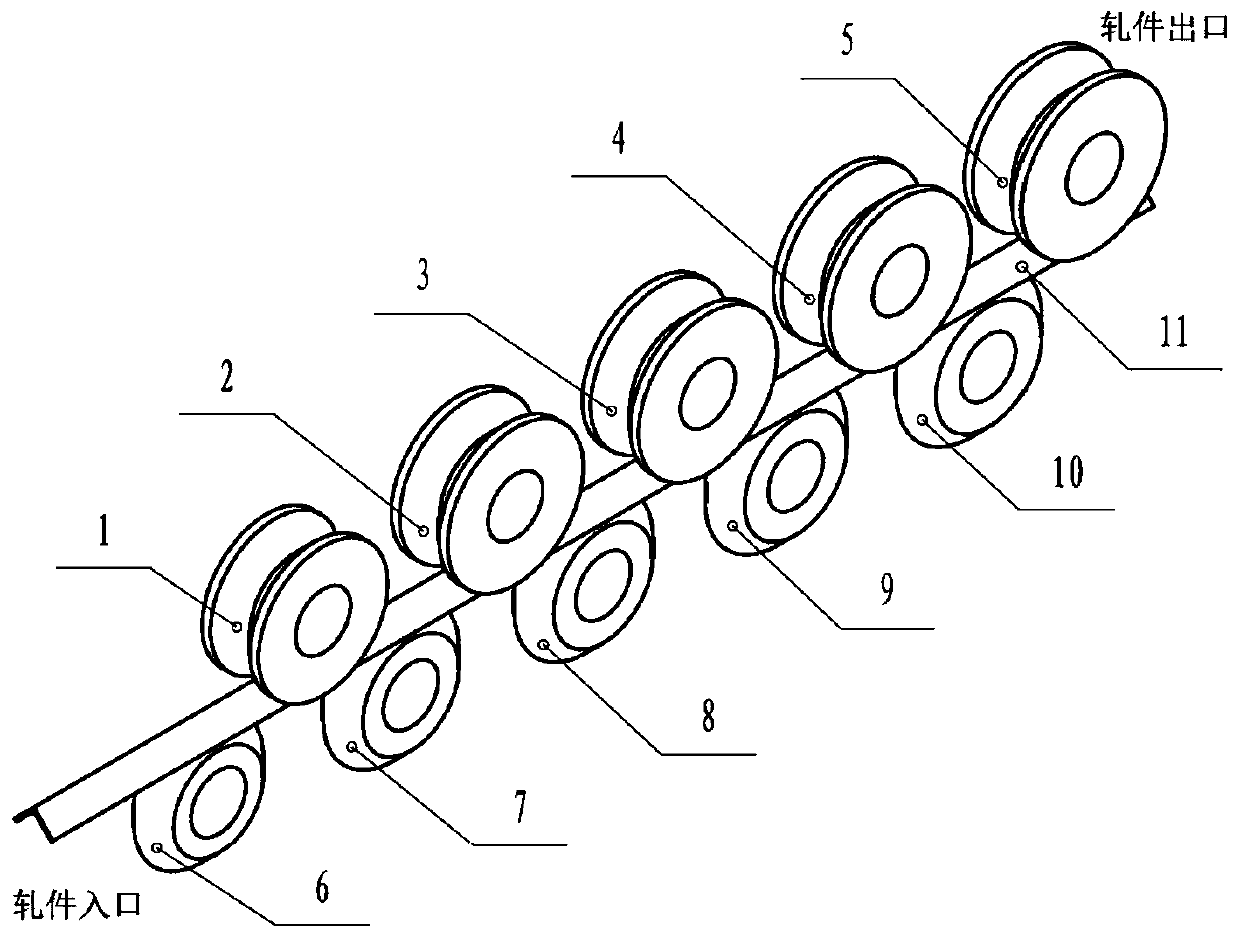

[0015] figure 1 , figure 2 It is a continuous variable curvature section steel straightening machine, and the pass layout diagram of the straightening rolls for different types of steel, including 1#~5# upper straightening rollers, 6#~10# lower straightening rollers and rolled pieces 11.1 #~10# The pass shape of the straightening roller can be changed to figure 1 , figure 2 different arrangements. From the entrance of the rolled piece to the exit of the rolled piece, the roll necks of each straightening roll gradually increase. The upper straightening rolls of 1# to 5# adopt an independent pressing device, which can be realized by small pressing in the first few passes. The large deformation straightening process solves the problem of excessive straightening force, excessive wear of the straightening rollers, excessive energy consumption and roll consumption in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com