Excavator bucket type amphibious dredge pumping ship

An amphibious and dredging pump technology, which is applied to amphibious vehicles, earth movers/shovels, motor vehicles, etc., can solve problems such as low work efficiency, great environmental damage, and heavy dredging work tasks, and achieve adaptation to The effect of improved range, improved transportation convenience, automatic screening debris pumping distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

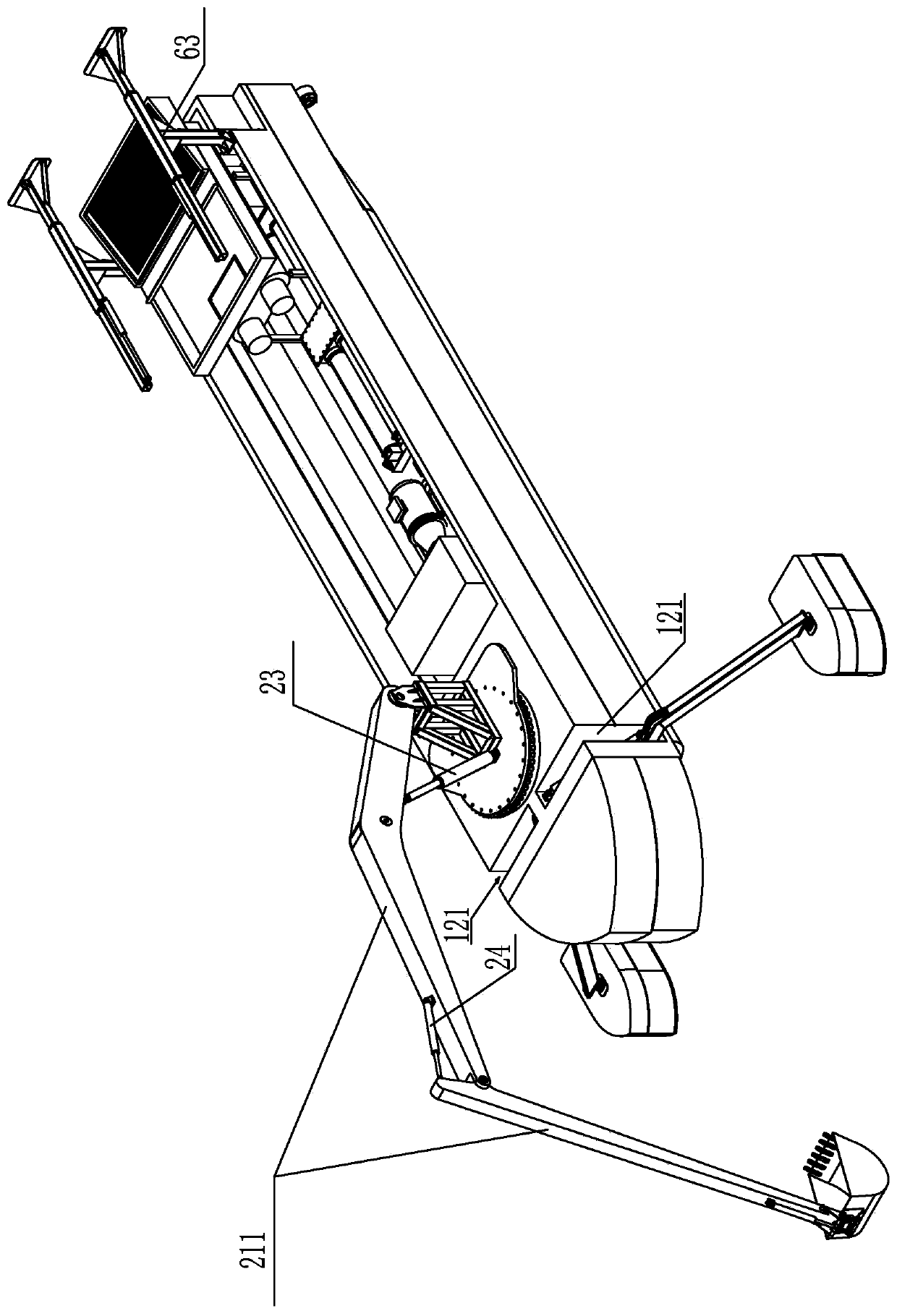

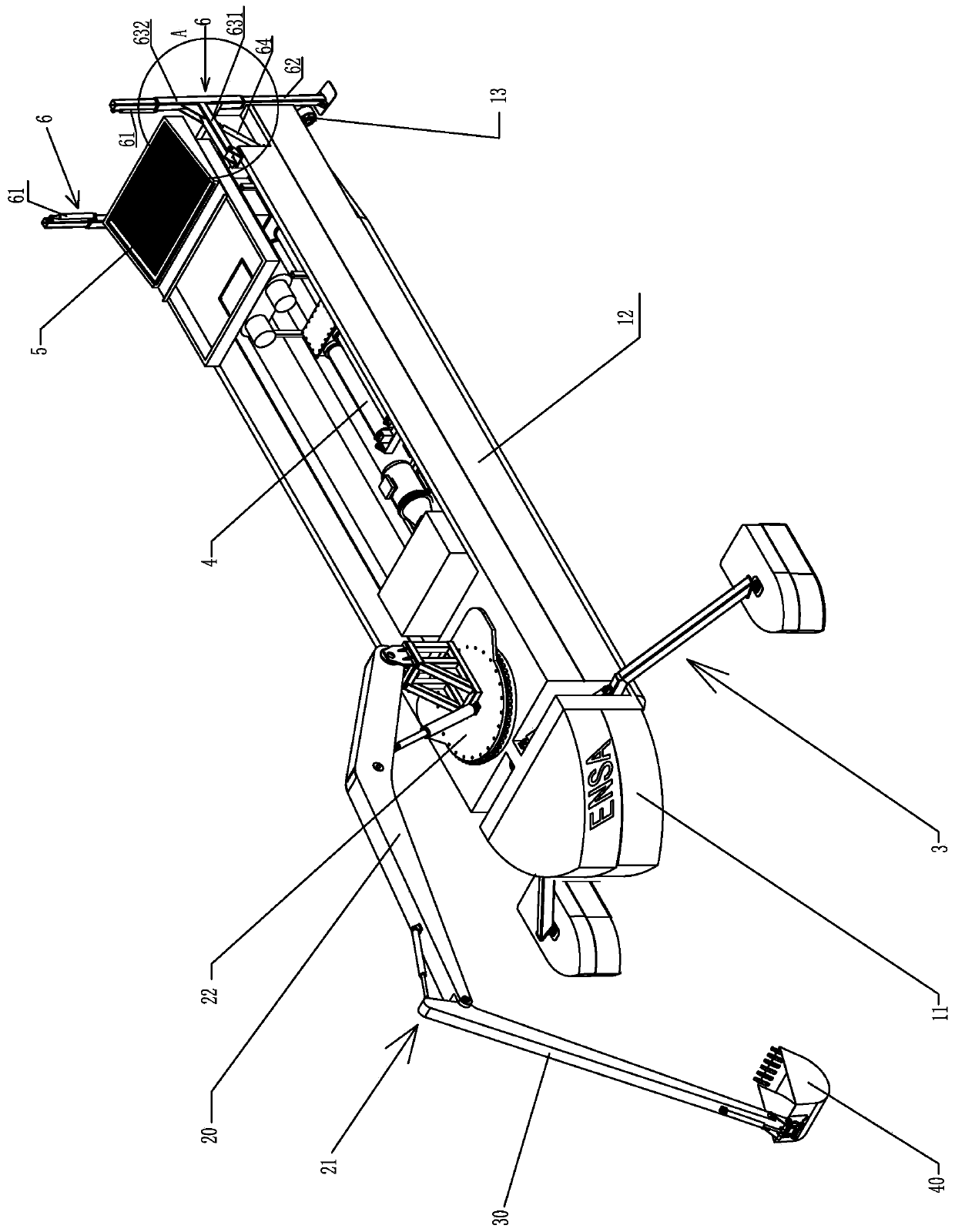

[0018] see Figure 1 to Figure 4 As shown, a bucket-type amphibious dredging pumping ship includes a hull 1, the hull includes a bow 11 and a hull 12, and two sets of screw propellers 13 are installed under the stern of the hull 12. The front portion of the hull 12 is equipped with a rotary dredging mechanism 2, and is provided with installation grooves 121 on both side walls of the hull near the bow respectively, and front leg support mechanisms 3 are respectively installed on the wall surfaces of each installation groove 121. A swing tube pump 4 is installed in the hull, and a sludge screening mechanism 5 is arranged at the stern of the hull 12. The sludge outlet of the sludge screening mechanism 5 corresponds to the inlet of the feeding screw (not shown in the figure), The outlet of the feeding screw corresponds to the inlet of the swing tube pump 4, the feeding screw is installed on the swing tube pump 4, and the debris outlet of the sludge screening mechanism 5 correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com