Integral lifting construction method for aluminum panel curtain wall of super-large double-curvature integrated unit

An integrated unit and overall improvement technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of difficult operation by personnel, prolonged construction period, difficult quality assurance, etc., to save trial and error costs, solve theoretical difficulties, and eliminate safety. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

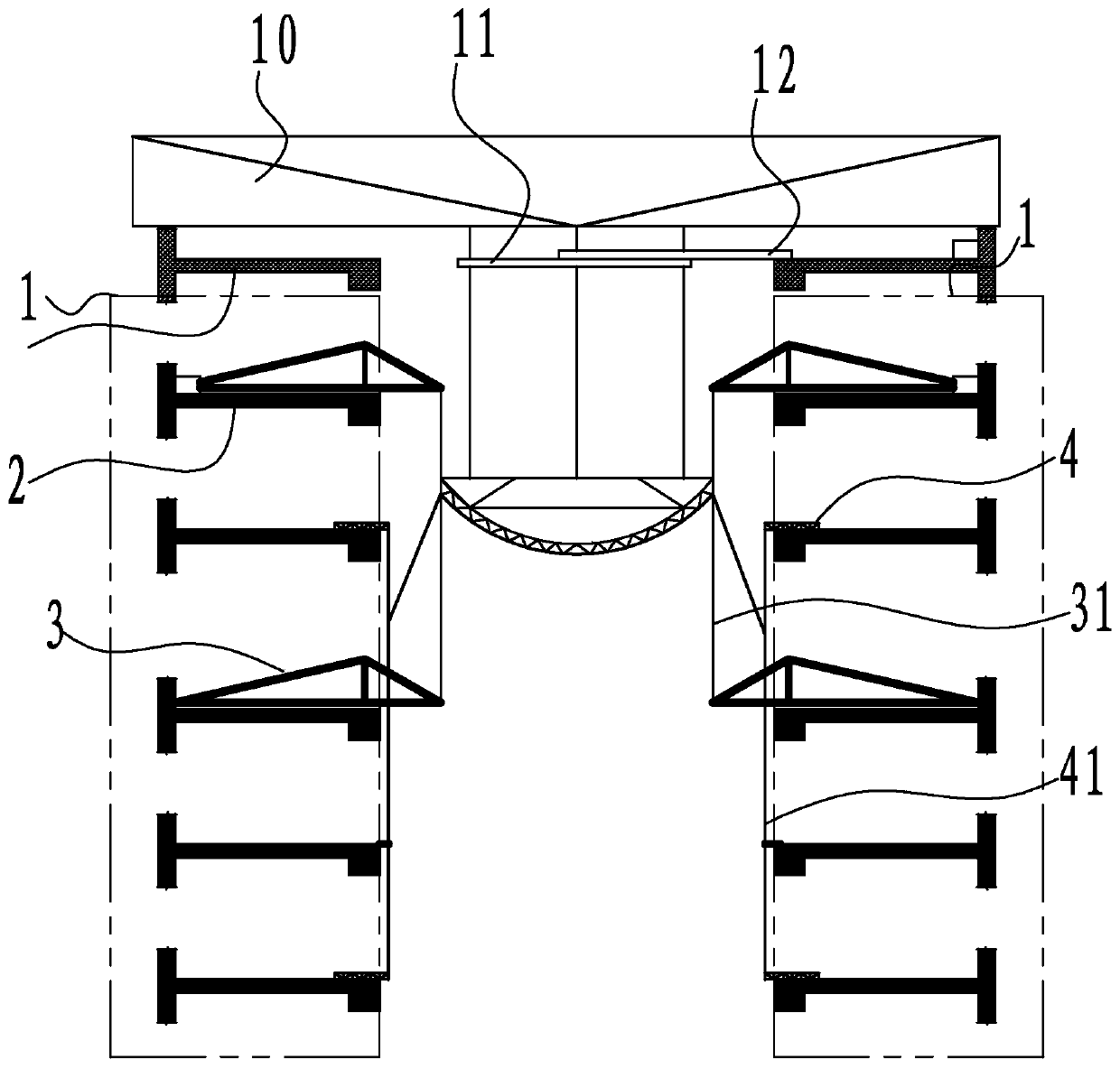

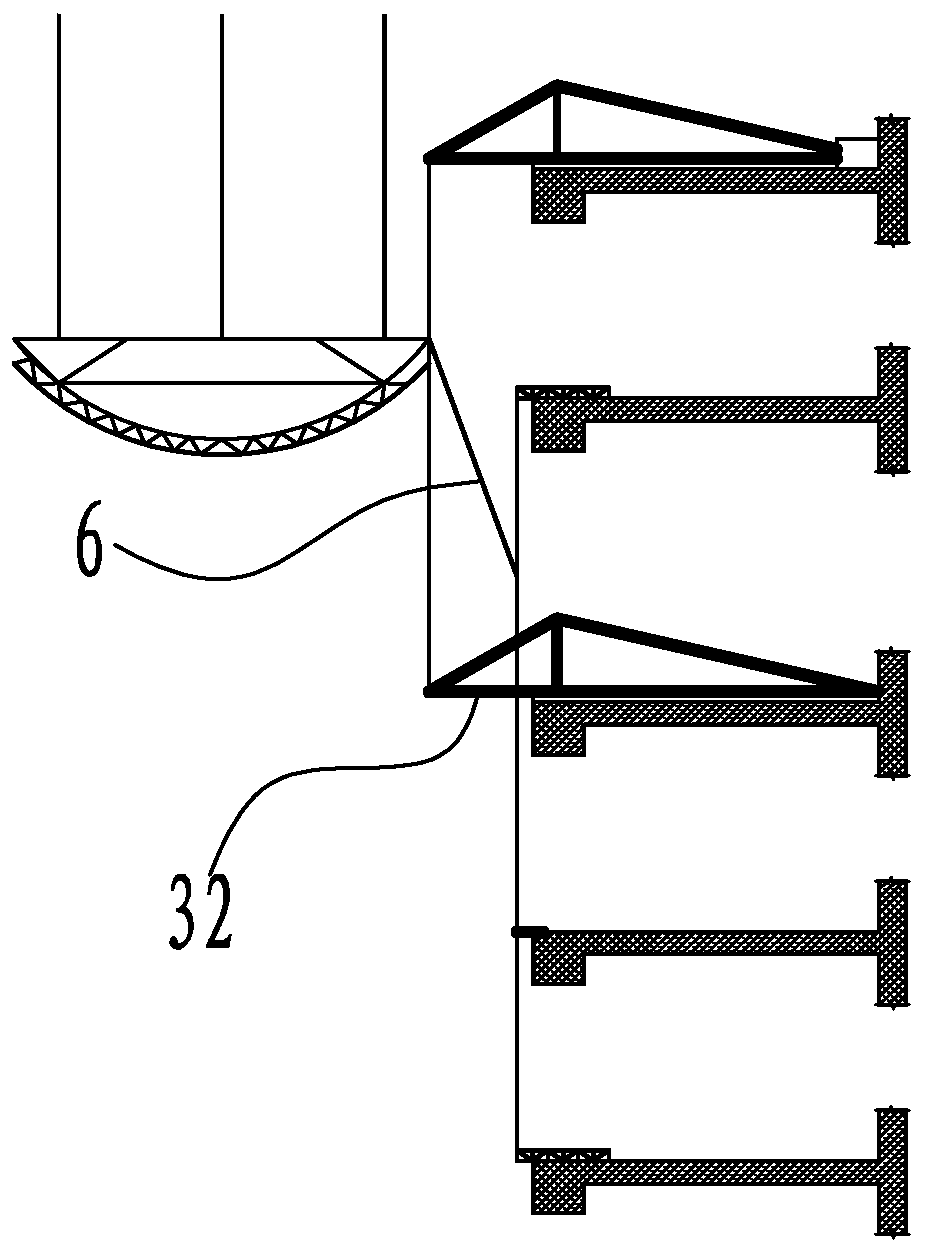

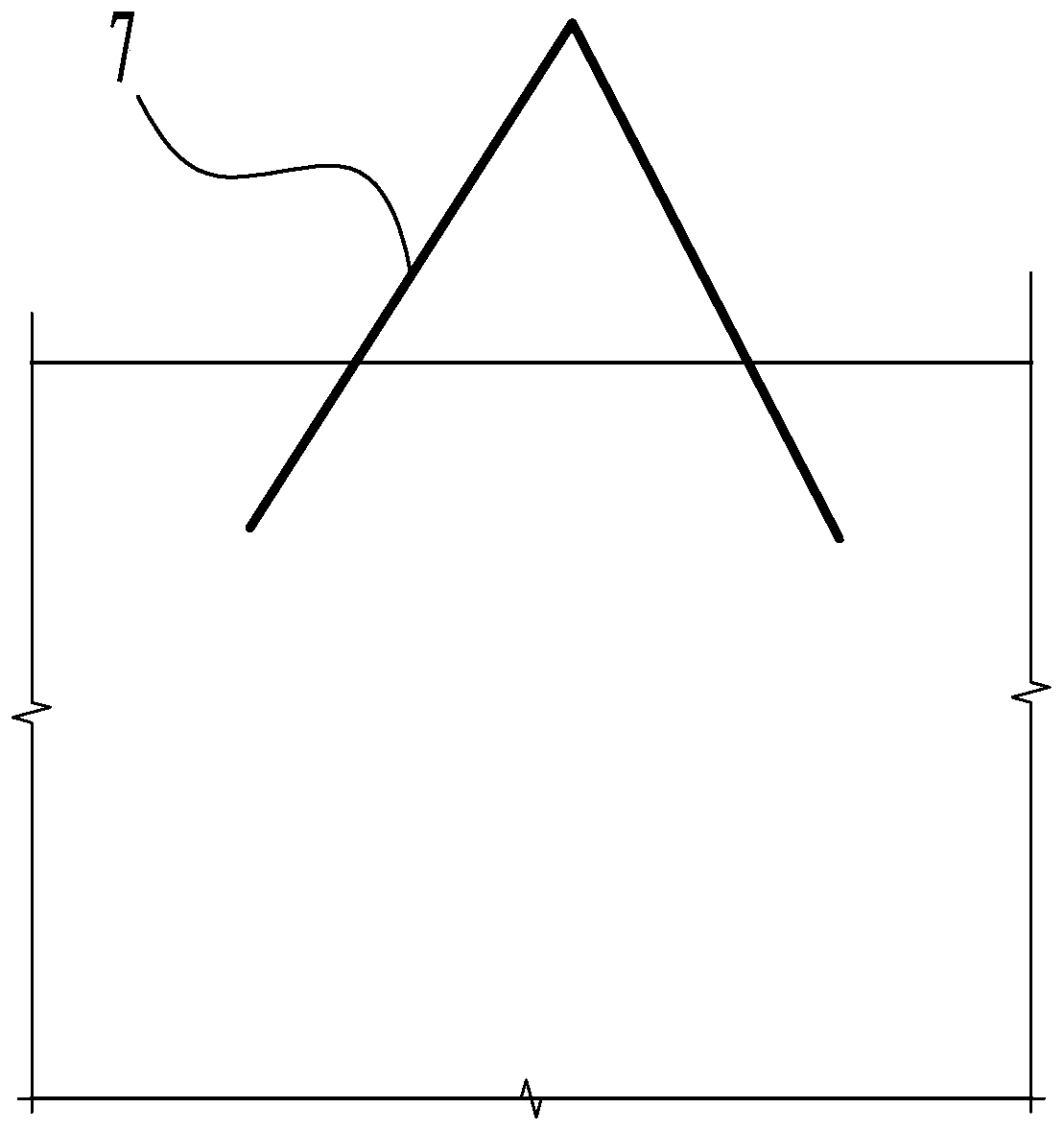

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 as well as Figure 6 As shown, the overall lifting construction method of an ultra-large hyperbolic integrated unit aluminum panel curtain wall disclosed by the present invention is suitable for the overall hoisting construction of an ultra-large integrated unit aluminum panel curtain wall, especially suitable for the overall hoisting construction of an ultra-large integrated unit aluminum panel curtain wall with a hyperboloid surface. It mainly includes the following construction features: super large integrated unit overall assembly tire frame platform construction technology; super large integrated unit overall BIM simulation analysis; super large integrated unit overall upgrading technology. For the convenience of description and illustration in this embodiment, the construction m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com