Combined tillage machine for returning dry-land straw to field by ploughing and rotary burying

A ploughing machine and straw technology, which is applied to ploughs, harvesters, agricultural machinery, etc., can solve the problems of insufficient ploughing depth and unstable straw amount, so as to increase the ploughing width, reduce the number of ploughs, and reduce the torque. and power effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with specific embodiments, so that those skilled in the art can understand.

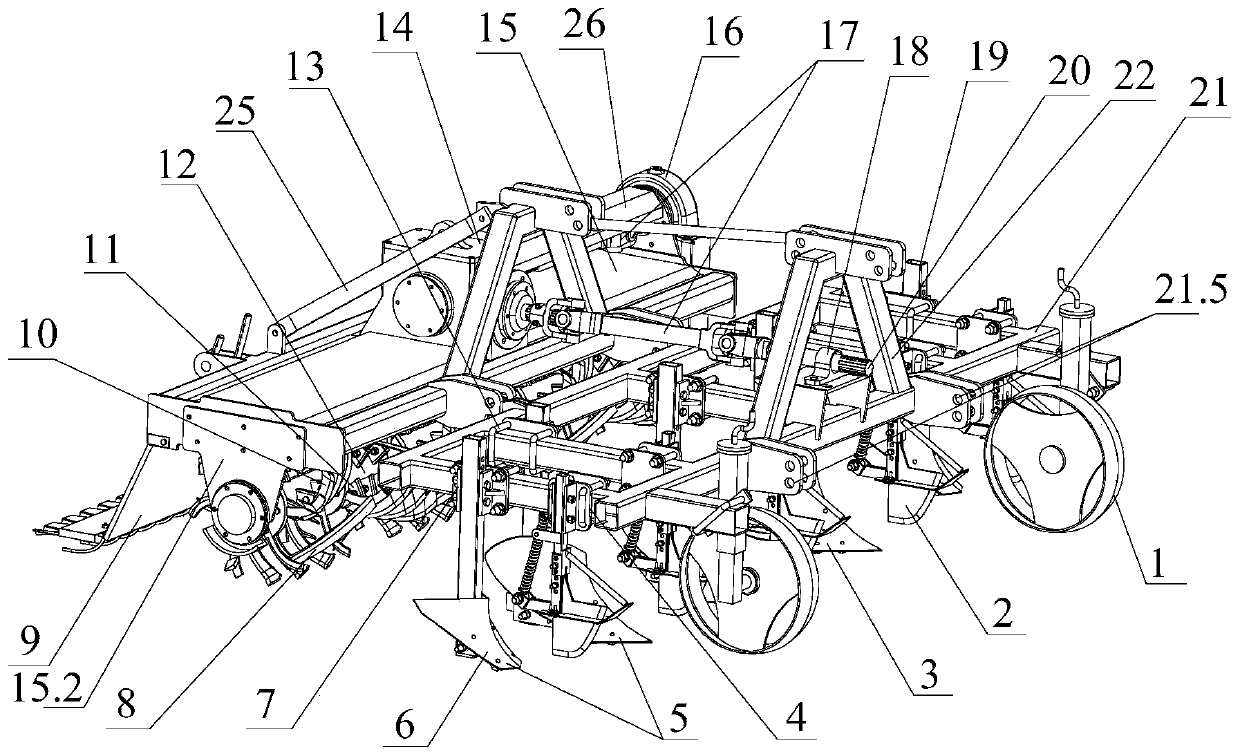

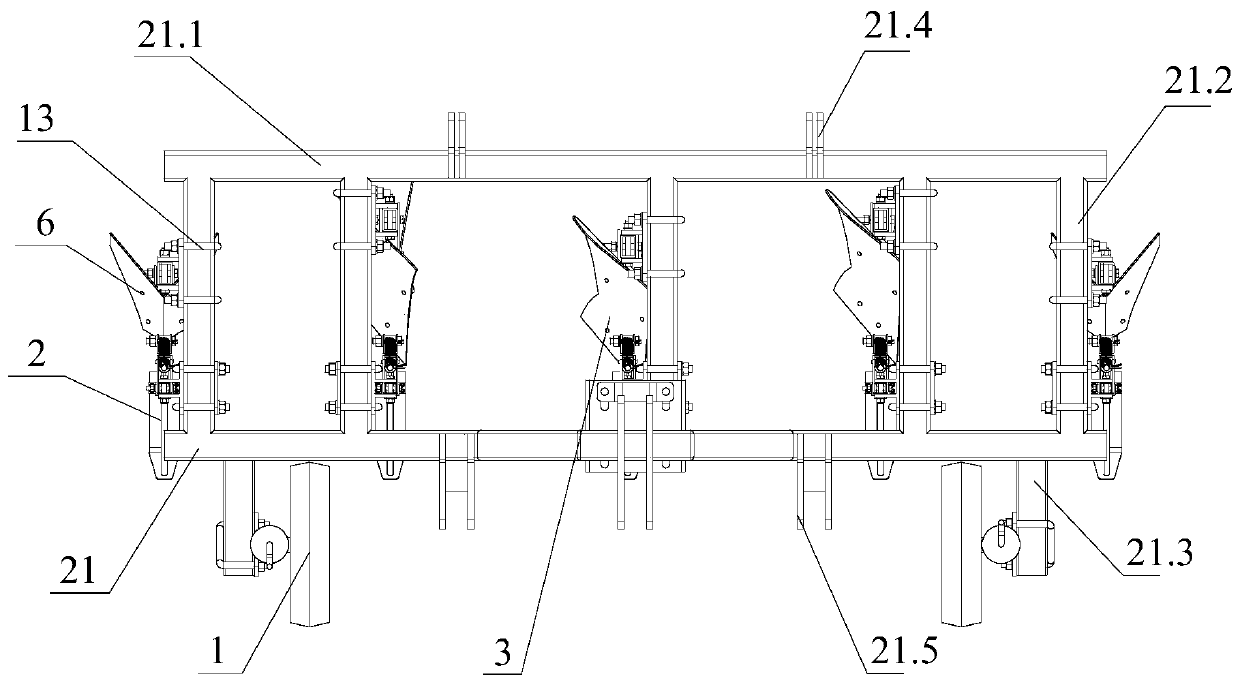

[0032] like Figure 1-7 The shown combined plowing machine for plowing and returning dry land straw includes a plowing device 5; A width bar 21.2, each width bar 21.2 one end is provided with an anti-wrapping grass device 2, and the anti-wrapping device 2 is fixed on the width bar 21.2 by the cutter splint 4 and the U-shaped bolt 13;

[0033]The other end of the width bar 21.2 on both sides of the frame is provided with a furrowing plow 6, and the plow column 19 above the furrowing plow 6 is fixed on the width bar 21.2 through the cooperation of the plow body splint 7 and the U-shaped bolt 13. The other end of a width bar 21.2 is provided with a soil-breaking plow 3, and the length bar 21.1 at one end of the frame 21 is symmetrically provided with a support frame 21.3. The hooking clamps 21.4 are arranged symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com