Experimental Evaluation Method for Oxygen Sensitivity of Oil and Gas Reservoirs

An evaluation method and technology for oil and gas layers, which are applied in material inspection products, suspension and porous material analysis, soil material testing, etc., can solve the problems of not including the evaluation method of oxygen sensitivity experiment, and achieve short experimental time and operation technology. Simple, economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

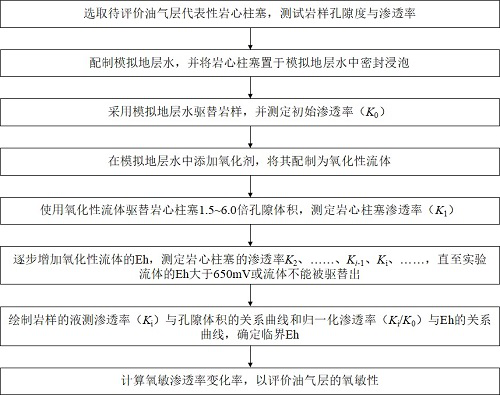

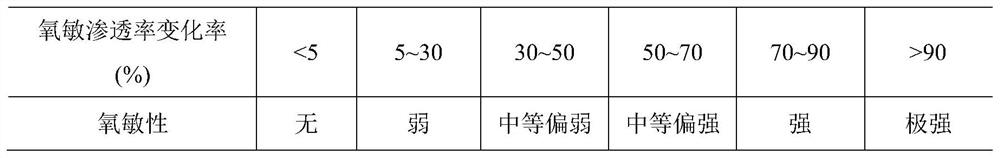

Method used

Image

Examples

Embodiment 1

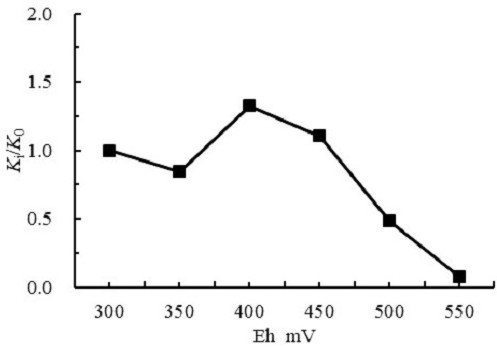

[0026] In order to verify the reliability of the present invention, the organic-rich shale samples of the Longmaxi Formation were used as experimental samples, and the prepared simulated formation water and oxidative fluid were used to determine the critical Eh value to evaluate the oxygen sensitivity of the shale reservoir. The specific operation steps are as follows:

[0027] (1) Prepare simulated formation water according to the salinity, ion concentration and redox potential of the reservoir fluid;

[0028] (2) Select the core plunger LM-1 to measure its length, diameter, mass, porosity and benchmark gas permeability;

[0029] (3) Create through fractures on the core plunger, remove the surface particles, and measure the basic parameters of the rock sample after fracture creation;

[0030] (4) Put the core plunger into the simulated formation water, seal and soak for 48h;

[0031] (5) Put the core plunger into the core holder, slowly apply a confining pressure of 3-10 MP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com