A high-efficiency ceramic glaze sealing device

A ceramic sealing and high-efficiency technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of endangering the health of operators, labor-intensive manual glazing, and complicated manual glazing, and achieve the effect of ensuring physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

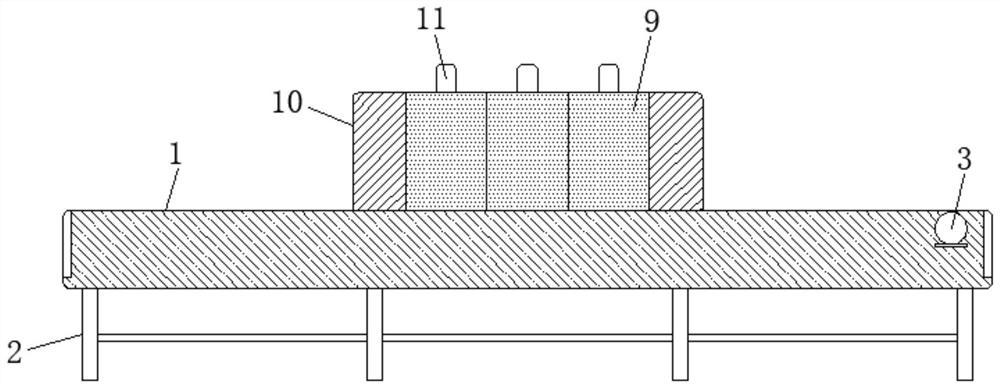

[0029] Embodiment one, by figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Provided, the present invention includes a transmission trough 1, the bottom of the transmission trough 1 is fixedly installed with a support leg 2, and one end of the surface of the transmission trough 1 is fixedly installed with a first motor 3, and through the setting of the first motor 3, it is possible to give the transmission Mechanism 4 provides power for transmission. Transmission mechanism 4 is installed inside transmission slot plate 1. Three rotating mechanisms 5 are installed in the middle of transmission mechanism 4. Fixed mechanism 6 is installed in the middle of three rotating mechanisms 5. Three rotating mechanisms 5 The both sides of top are all provided with ceramic embryo body 7, are all provided with to hold clamping mechanism 8 between the top of two ceramic embryo bodies 7 and the both sides of fixing mechanism 6 tops, the middle part of transmission groove plate 1 top ...

Embodiment 2

[0030] Embodiment two, on the basis of embodiment one, by figure 2Given, the transmission mechanism 4 includes a main shaft 13, a main gear 14, a counter shaft 15, a sub gear 16 and a chain 1601, the main shaft 13 is movably installed at one end inside the transmission slot plate 1, and one end of the main shaft 13 is connected to the output of the first motor 3 The main gear 14 is fixedly connected to the two ends of the main shaft 13, the auxiliary shaft 15 is equidistantly installed inside the transmission slot plate 1, the auxiliary gear 16 is fixedly connected to the two ends of the auxiliary shaft 15, and the main gear at the two ends of the main shaft 13 A chain 1601 is connected between the gear 14 and the pinion gear 16 at the two ends of the countershaft 15. Through the arrangement of the main shaft 13, the main gear 14, the countershaft 15, the pinion gear 16 and the chain 1601, it can effectively clean the ceramic body. 7 for transmission.

Embodiment 3

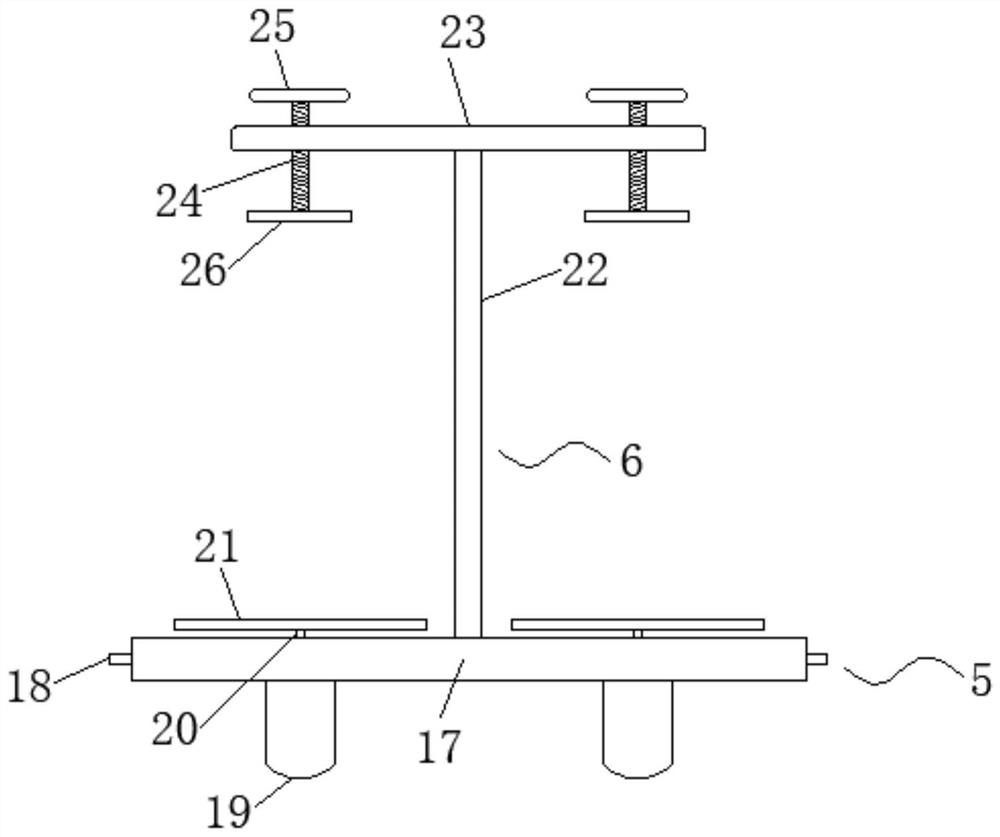

[0031] Embodiment three, on the basis of embodiment one, by image 3 Given, the three rotating mechanisms 5 all include a bottom plate 17, a connecting shaft 18, a third motor 19, a rotating shaft 20 and a placement plate 21, and the two sides of the three bottom plates 17 are fixedly connected to two chains 1601 through the connecting shaft 18 at equal distances. , the third motor 19 is fixedly installed on both sides of the bottom of the base plate 17, the rotating shafts 20 are respectively fixedly connected to the output ends of the two third motors 19, and one end of the two rotating shafts 20 extends to the top of the base plate 17 and is respectively connected to the placement plate 21 The stationary phase is connected, and through the setting of the bottom plate 17, the connecting shaft 18, the third motor 19, the rotating shaft 20 and the placement plate 21, it can drive a plurality of ceramic embryos 7 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com