Dumpling machine

A dumpling machine and rack technology, which is applied in baking, dough processing, food science, etc., can solve the problems of large production capacity limitations, increased equipment maintenance costs, and general low efficiency, and achieve high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

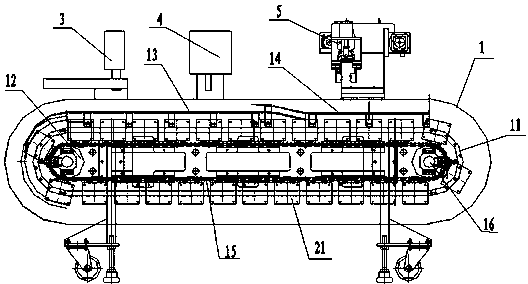

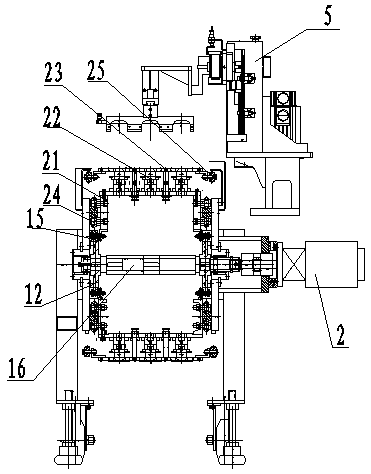

[0017] like figure 1 , 2 Shown, a kind of dumpling machine comprises frame 1, is installed in the driving motor 2 of frame outside, some wrapping moulds, punching device 3, filling device 4, kneading device 5.

[0018] The skin punching device 3, filling device 4, and kneading device 5 are arranged on the upper part of the frame 1 in sequence from front to back, and the skin outlet of the skin punching device 3, the filling port of the filling device 4, and the kneading claws of the kneading device 5 are facing each other. The skin-closing mold hole on the wrapping mold is used to make the dough punched by the skin punching device fall on the wrapping mold, and make the filling material fall on the middle of the dough, and finally knead the dough that has been filled and folded in half by the wrapping mold.

[0019] The frame 1 is formed by setting the left and right vertical plates in parallel. On the opposite sides of the left and right vertical plates, the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com