Two-dimensional primary and secondary compensation spray rotation steam pipe fast-switching device

A steam pipeline and quick switch technology, applied in the direction of valve devices, valve details, multi-way valves, etc., can solve the problems of inability to rotate, reduce work efficiency, and low work efficiency, so that it is not easy to wear, improve work efficiency, and reduce labor. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

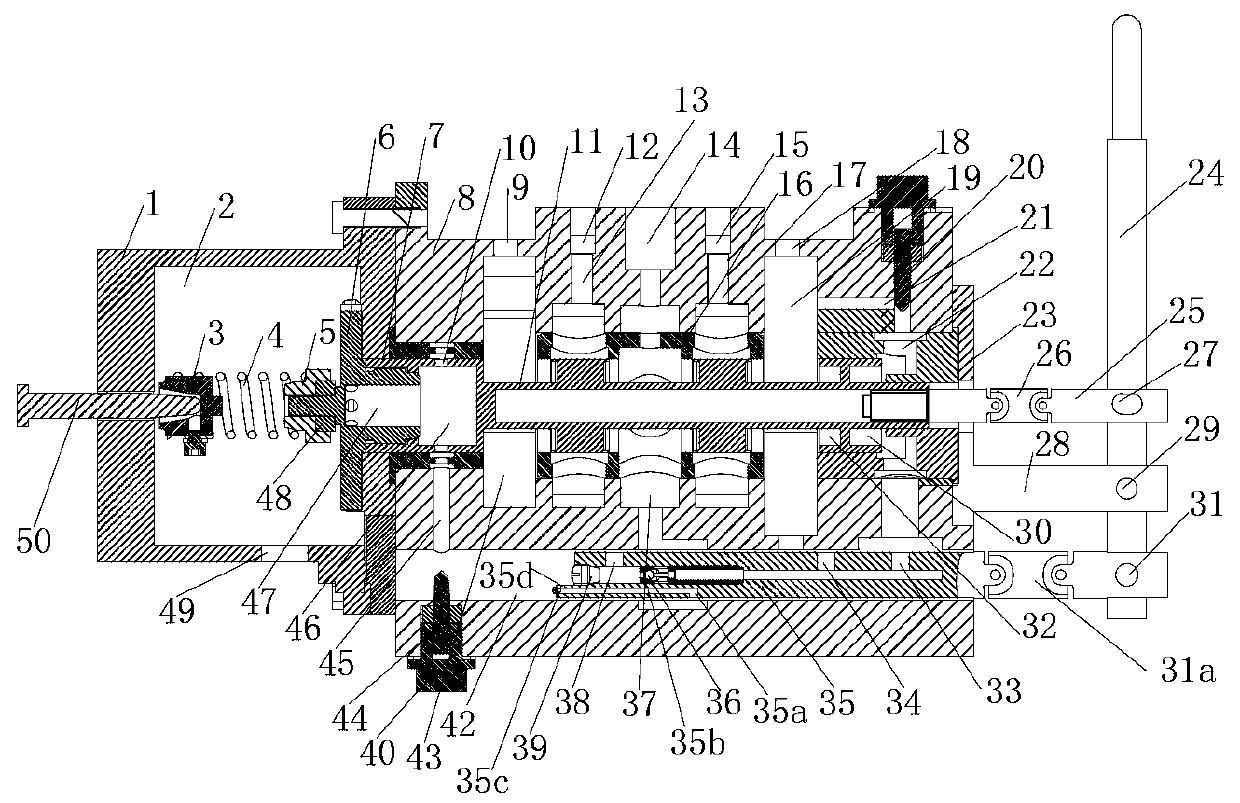

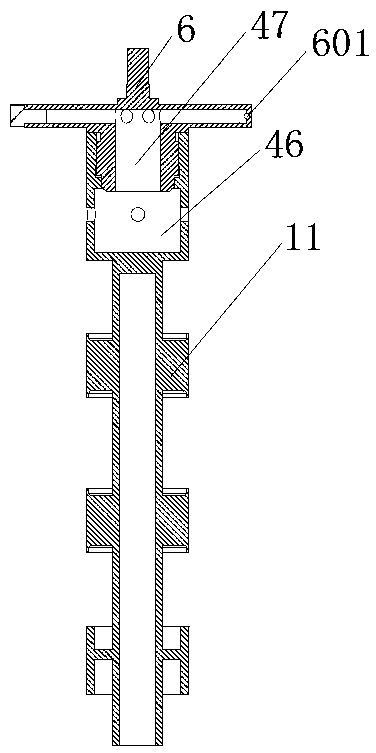

[0024] The present invention will be further described below in conjunction with the accompanying drawings of the description.

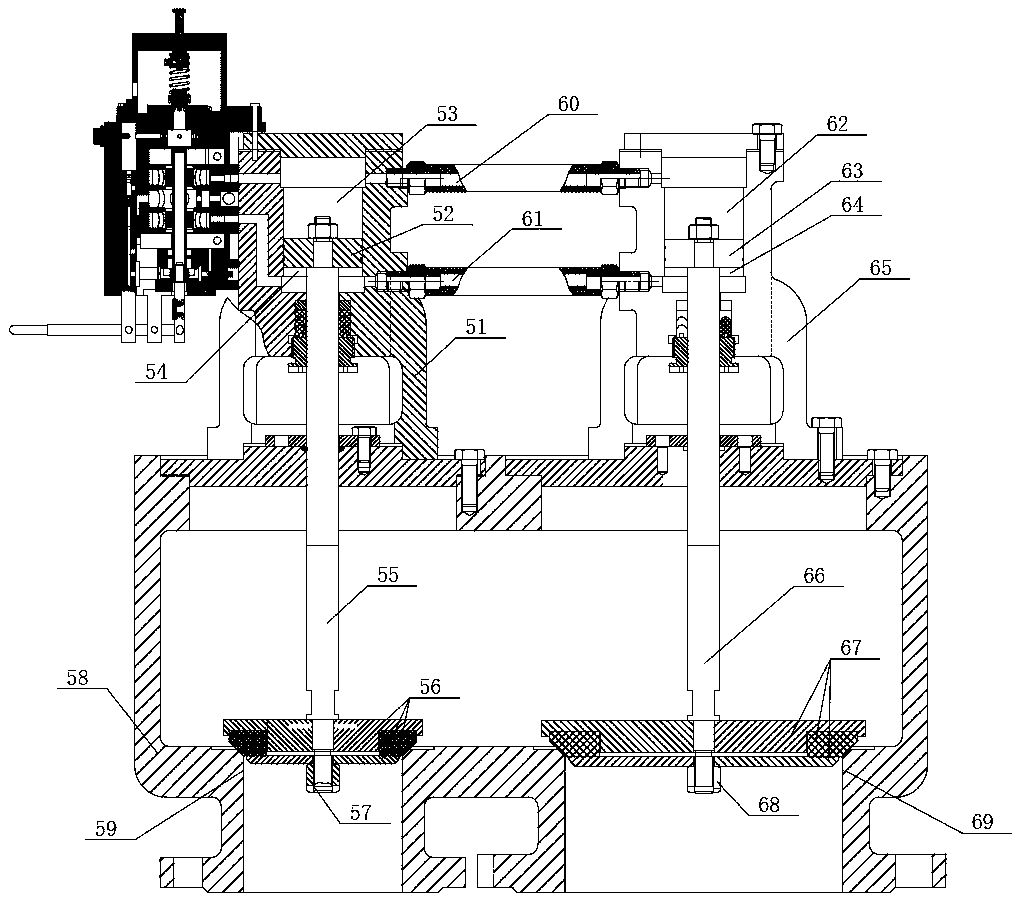

[0025] As shown in the figure, the pipeline safety manual switch valve includes a valve body 51, a valve stem 55 is arranged in the valve body 51 to cooperate with its sealing activity, a rear valve plate 52 is arranged at the rear of the valve stem 55, and the rear valve Plate 1 52 divides the valve body chamber into first valve chamber A53 and first valve chamber B54, valve stem 1 52 is provided with a valve disc 56 at the front end, and valve disc 1 56 extends into the cavity of pipeline 58 to seal fit or separate from pipeline mouth 1 59 Valve body one 51 outer side cooperates and arranges valve body two 65, valve stem two 66 that cooperates with its sealing activity is set in valve body two 65, valve stem two 66 rear parts are provided with rear valve plate two 63, and rear valve plate two 63 will valve body cavity Divided into the second valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com