Suction table with workpiece support for workpiece to be supported

A workpiece and support technology, applied in the field of suction table, can solve the problem of not being able to move freely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

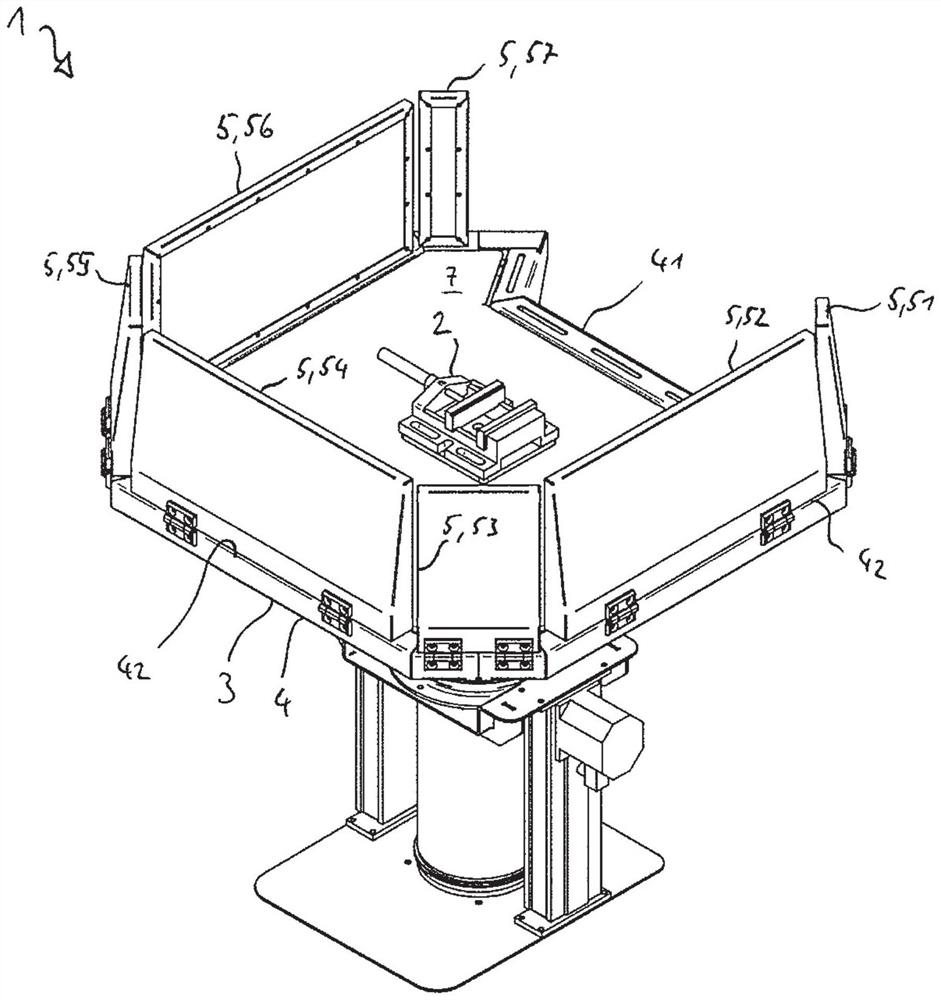

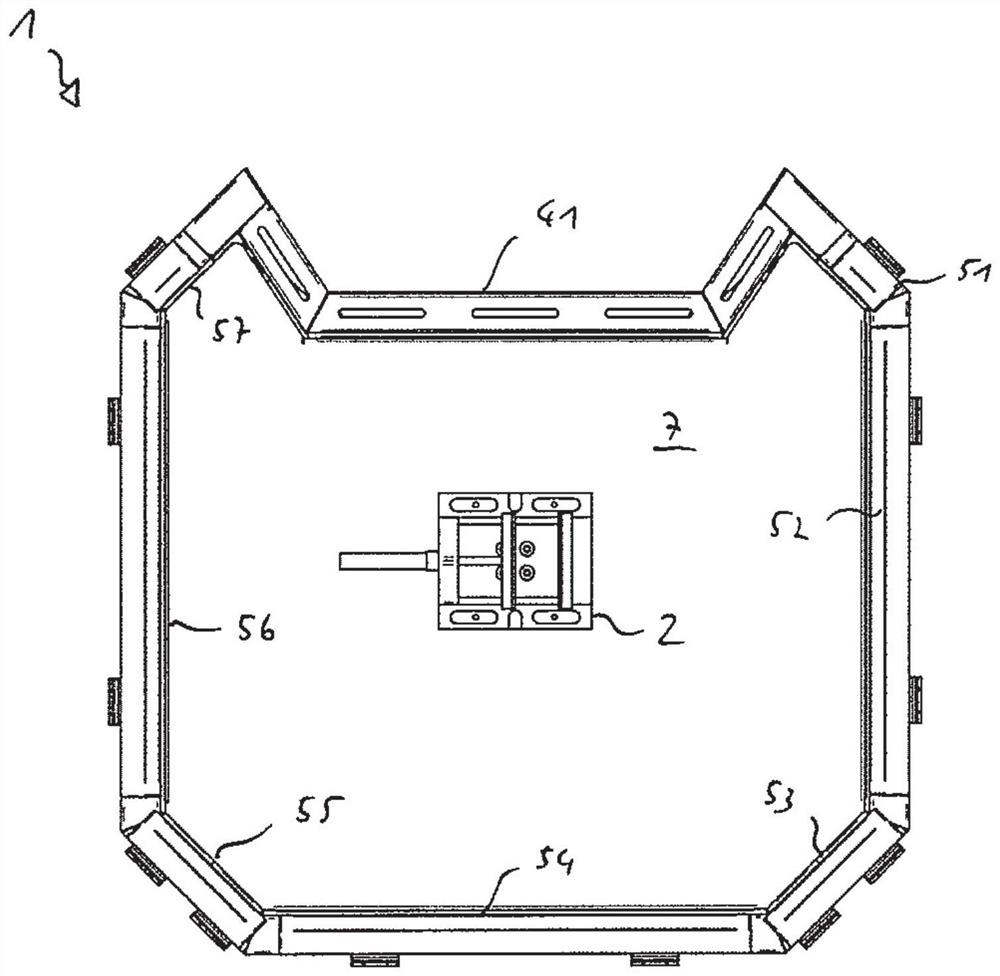

[0039] exist figure 1 An exemplary suction table 1 is shown with a workpiece support 2 for the workpiece to be supported.

[0040] The workpiece carrier 2 is designed to be fixed in position, below and to the side of the workpiece carrier 2 are arranged suction devices 3 , by means of which the particles and / or gases in the exhaust gas flow can be discharged downwards.

[0041] In this case, the suction device 3 is arranged relative to the workpiece carrier 2 around this workpiece carrier and is designed to be rotatable about the workpiece carrier 2 .

[0042] The suction device 3 is designed in the form of a cap 4, see also figure 2 , and has a recess 41 on one side for the person P working on the suction table 1 .

[0043] The suction device 3 has a plurality of hinged side walls 5 , 51 to 57 on the upper edge 42 of the cap 4 .

[0044] The side walls are not hinged in the region of the recess 41 in order to enable free access for workers.

[0045] The suction device 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com