Automatic stacking device

A technology for automatic stacking and installation of panels, which is applied in the direction of conveyor control devices, object stacking, transportation and packaging, etc., and can solve problems such as complex equipment structure, limited weight of stacking pallets, and incomplete functions of automatic stacking devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

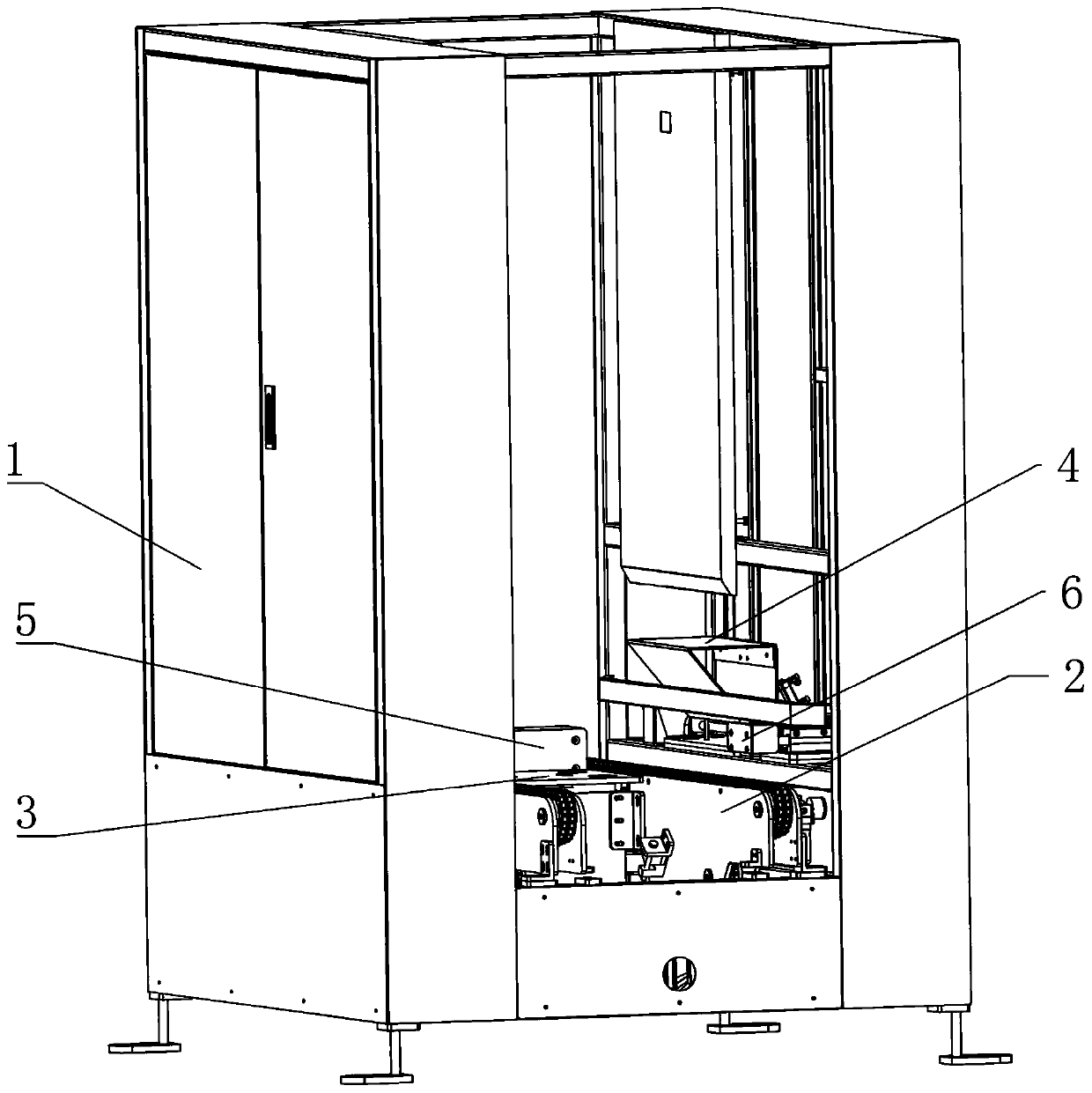

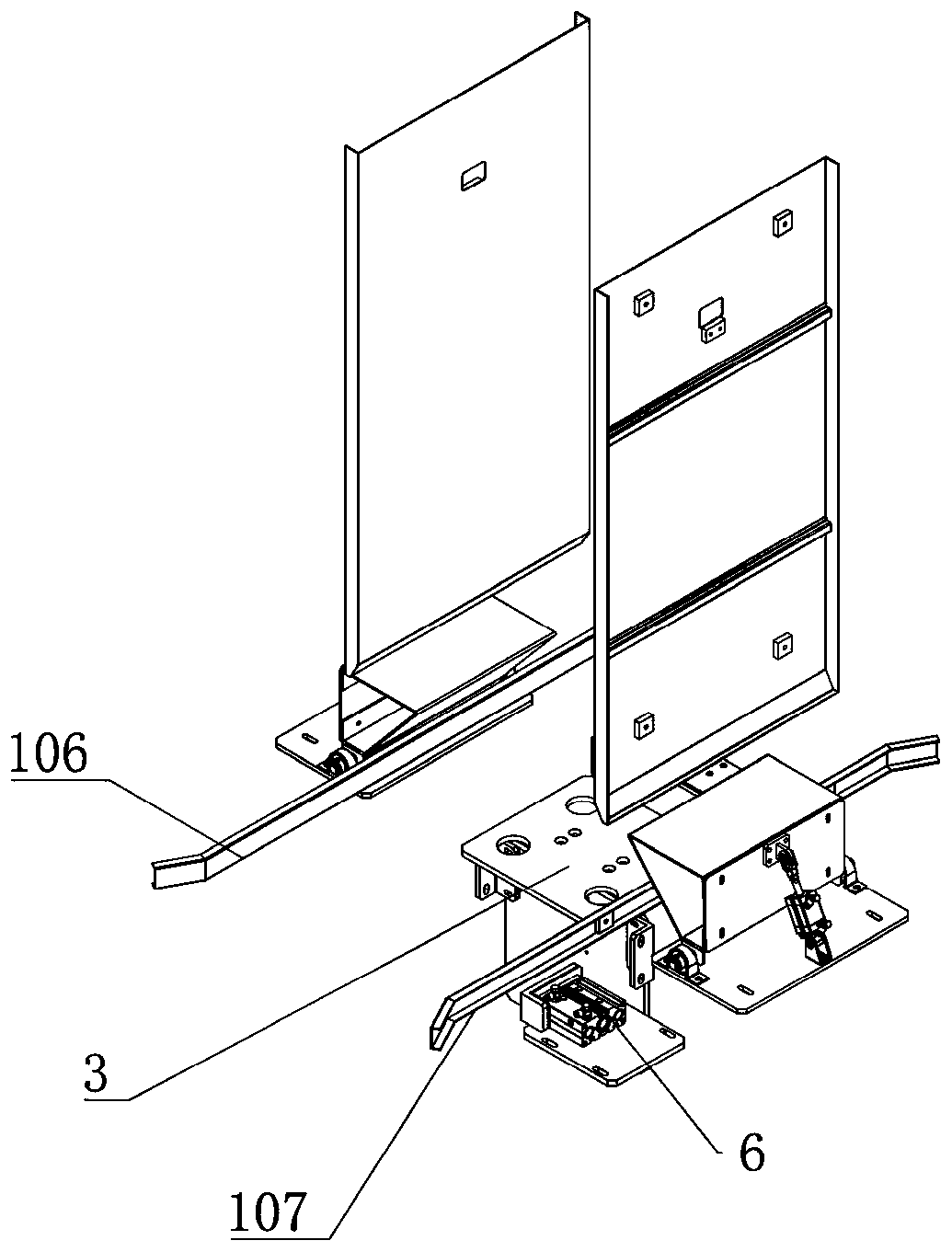

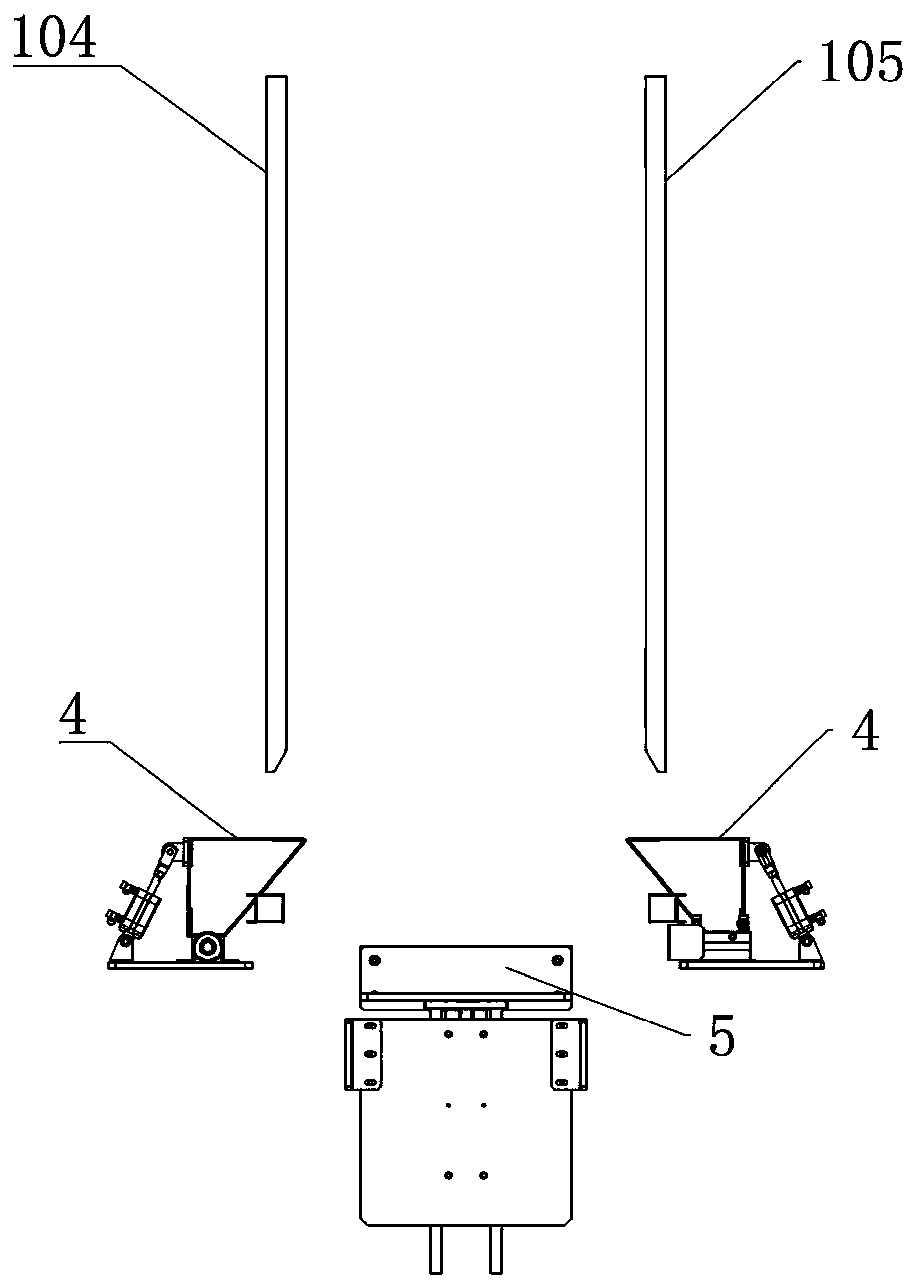

[0103] like Figures 1 to 8-2 Shown, in this embodiment, automatic stacking device of the present invention comprises:

[0104] Conveyor module, used to convey materials to designated positions preset by the system;

[0105] The material carrying module is located above the specified position and is used to store the material;

[0106] Lifting module, used to lift the material located at the specified position to the material carrying module;

[0107] The control module is respectively connected with the conveying module, the material carrying module and the lifting module.

[0108] In order to make it easier for those skilled in the art to understand the positional relationship of the various mechanisms in this embodiment, the attached Picture 1-1 and 1-2 allow thos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com