Oxygen-free copper rod material forming and take-up device

A technology of material forming and oxygen-free copper rods, which is applied in the field of oxygen-free copper rod material forming and collecting devices, can solve the problems of low efficiency, increased manpower and working time, and easy collection of irregularities, so as to achieve the effect of improving collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

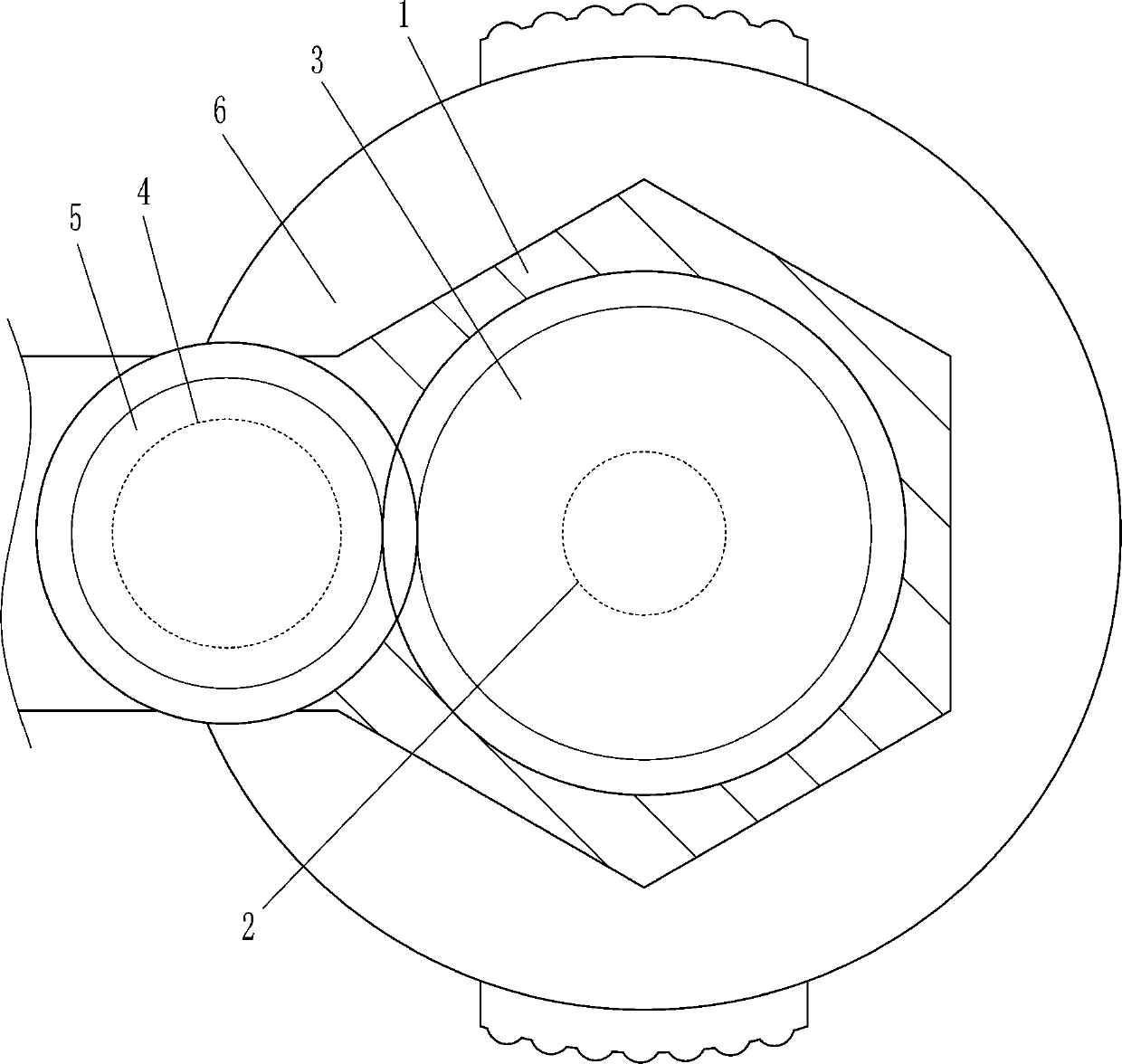

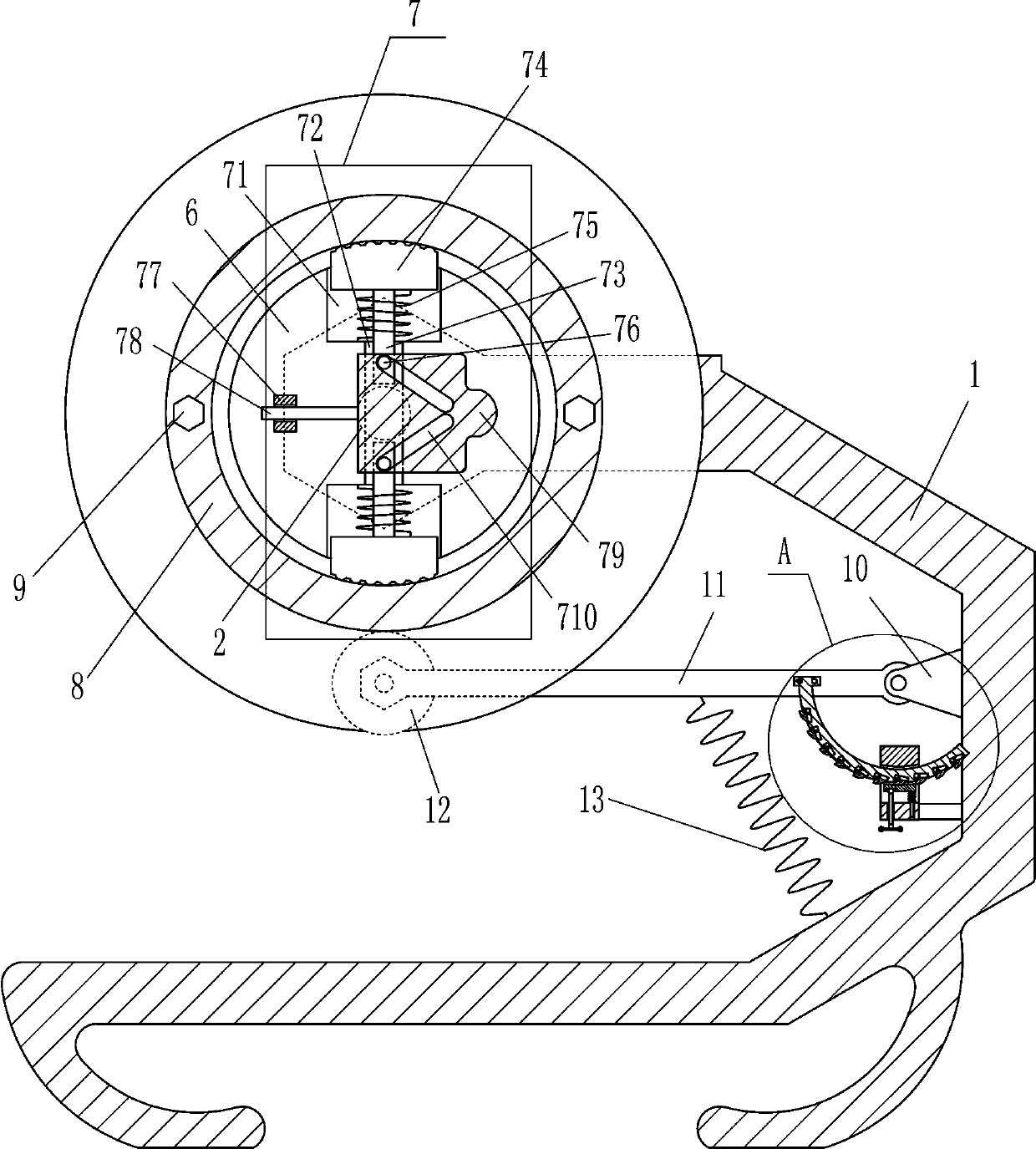

[0016] An oxygen-free copper rod material forming and collecting device, such as Figure 1-2 As shown, it includes a support 1, a rotating shaft 2, a first gear 3, a motor 4, a second gear 5, a rotating disk 6, a telescoping device 7 and a hollow drum 8, and the left side of the support 1 is rotated to be provided with a rotating shaft 2. After the rotating shaft 2 There is a first gear 3 at the end, the rotating shaft 2 is connected with the first gear 3 by welding, a motor 4 is arranged on the rear side of the upper part of the bracket 1, and a second gear 5 is arranged on the output shaft of the motor 4, and the second gear 5 is connected with the The first gear 3 meshes, and the front end of the rotating shaft 2 is provided with a turntable 6, and the rotating shaft 2 is connected to the turntable 6 by welding. Both have first through holes 9 .

Embodiment 2

[0018] An oxygen-free copper rod material forming and collecting device, such as Figure 1-2 As shown, it includes a support 1, a rotating shaft 2, a first gear 3, a motor 4, a second gear 5, a rotating disk 6, a telescoping device 7 and a hollow drum 8, and the left side of the support 1 is rotated to be provided with a rotating shaft 2. After the rotating shaft 2 A first gear 3 is provided at the end, a motor 4 is provided on the rear side of the upper part of the bracket 1, a second gear 5 is provided on the output shaft of the motor 4, the second gear 5 meshes with the first gear 3, and a turntable 6 is provided at the front end of the rotating shaft 2. A telescoping device 7 is provided on the turntable 6, and a hollow cylinder 8 is sheathed on the turntable 6, and first through holes 9 are opened on the left and right sides of the hollow cylinder 8.

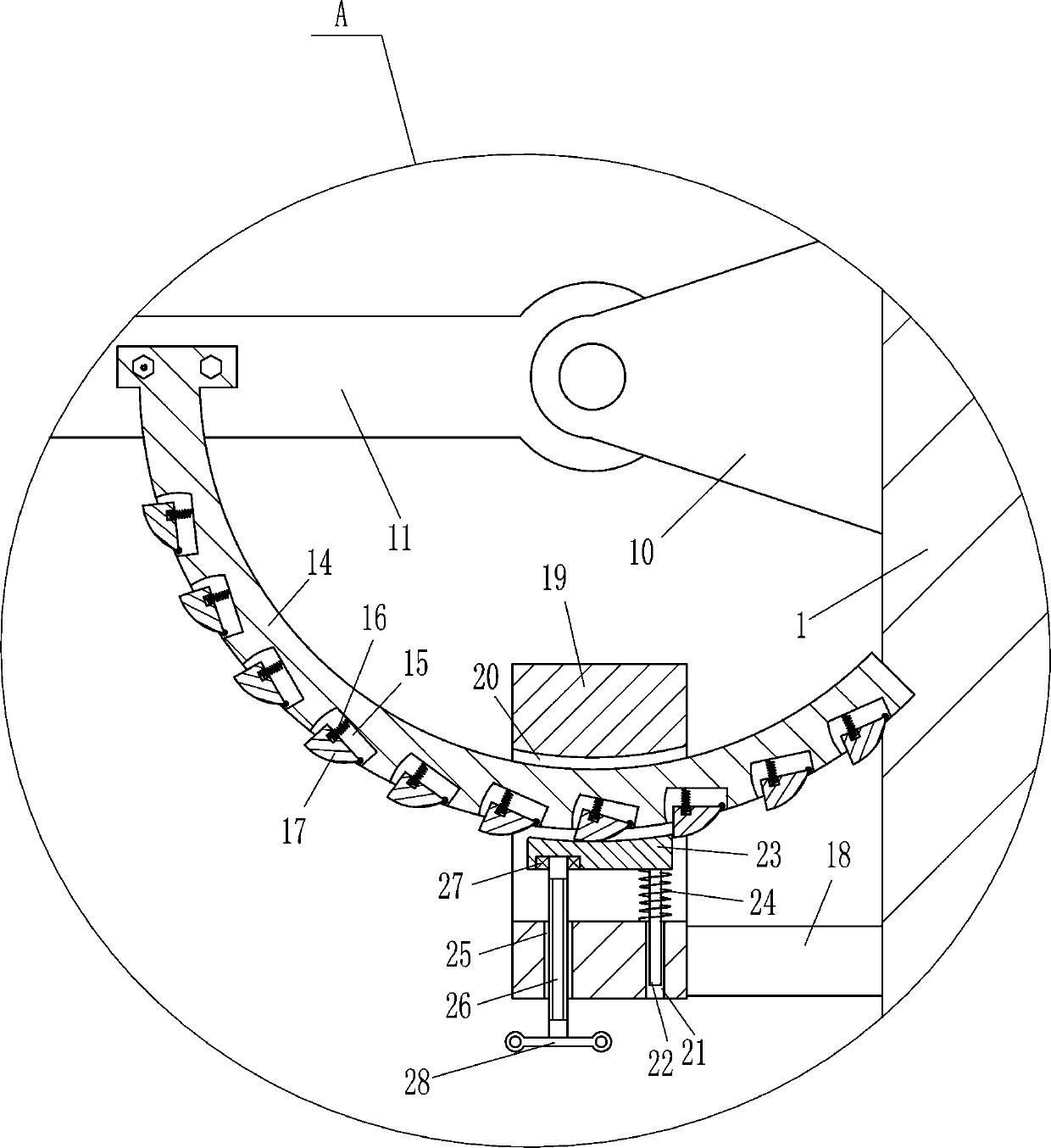

[0019] Telescopic device 7 comprises first slide bar 73, arc block 74, first spring 75, pin bar 76, sliding sleeve 77, se...

Embodiment 3

[0021] An oxygen-free copper rod material forming and collecting device, such as Figure 1-2 As shown, it includes a support 1, a rotating shaft 2, a first gear 3, a motor 4, a second gear 5, a rotating disk 6, a telescoping device 7 and a hollow drum 8, and the left side of the support 1 is rotated to be provided with a rotating shaft 2. After the rotating shaft 2 A first gear 3 is provided at the end, a motor 4 is provided on the rear side of the upper part of the bracket 1, a second gear 5 is provided on the output shaft of the motor 4, the second gear 5 meshes with the first gear 3, and a turntable 6 is provided at the front end of the rotating shaft 2. A telescoping device 7 is provided on the turntable 6, and a hollow cylinder 8 is sheathed on the turntable 6, and first through holes 9 are opened on the left and right sides of the hollow cylinder 8.

[0022] Telescopic device 7 comprises first slide bar 73, arc block 74, first spring 75, pin bar 76, sliding sleeve 77, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com