Multi-axis random load fatigue life prediction method

A technology of fatigue life prediction and random load, which is applied in the fields of instrumentation, computing, and electrical digital data processing, etc., can solve the problems of particularly high time and space complexity requirements, less obvious engineering application significance, and a large amount of machine hours, etc., to achieve The effect of improving the life prediction ability and simplifying the prediction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

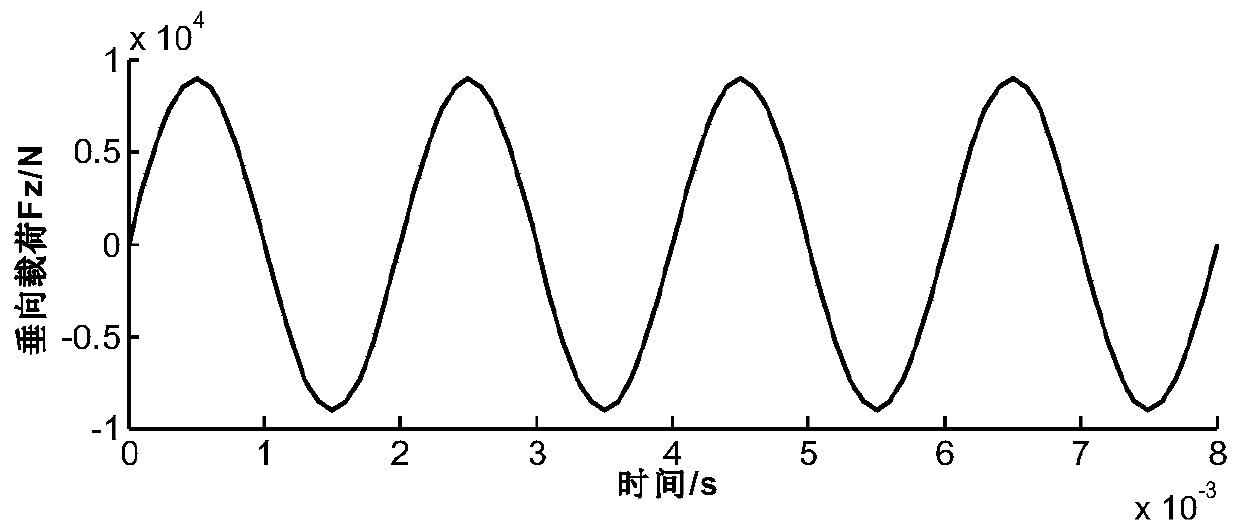

[0032]The multi-axial random load fatigue life prediction method in this embodiment is to obtain the position of the structural dangerous point and extract the key load through the finite element method for each random load on the component; classify the key load; The combined load spectrum block; based on the principle of linear damage accumulation, the fatigue life under multi-axial constant amplitude load fatigue life estimation method is used to predict the fatigue life under multi-axial random loads.

[0033] In this embodiment, the multiaxial random load fatigue life prediction method is carried out as follows:

[0034] Step 1: For each random load on the component, the dangerous points and key loads of the component structure are obtained as follows, and the key loads are classified.

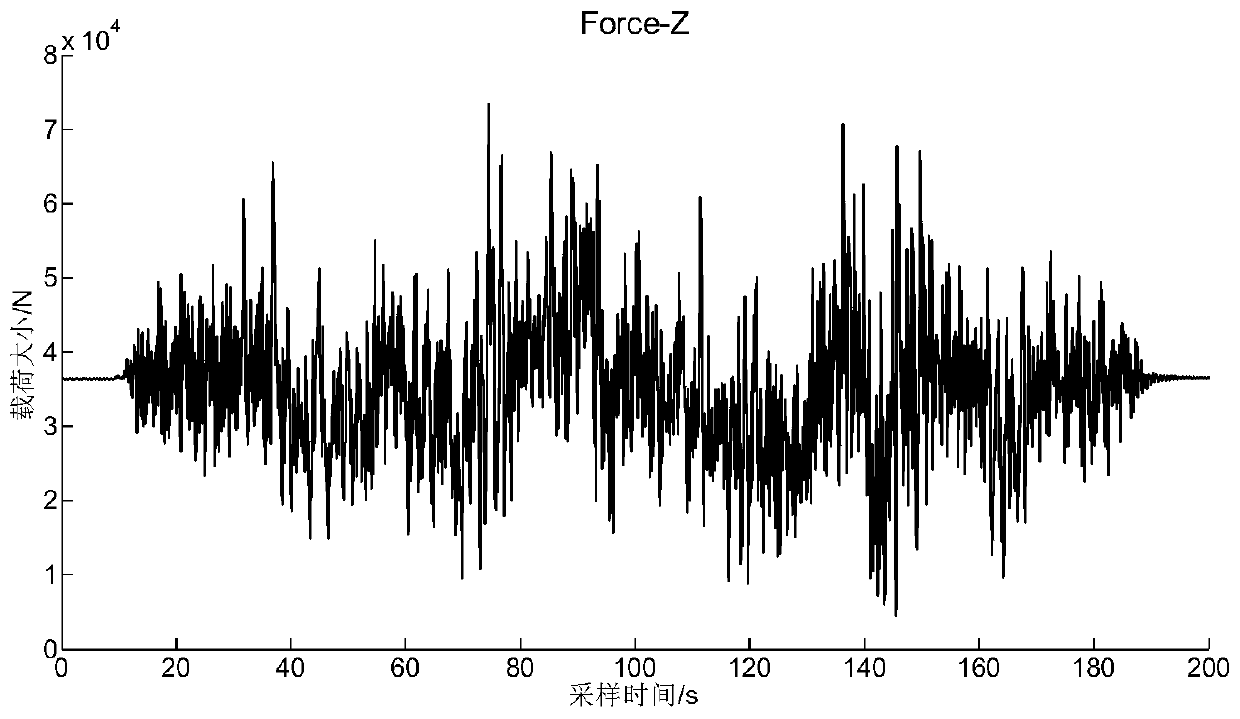

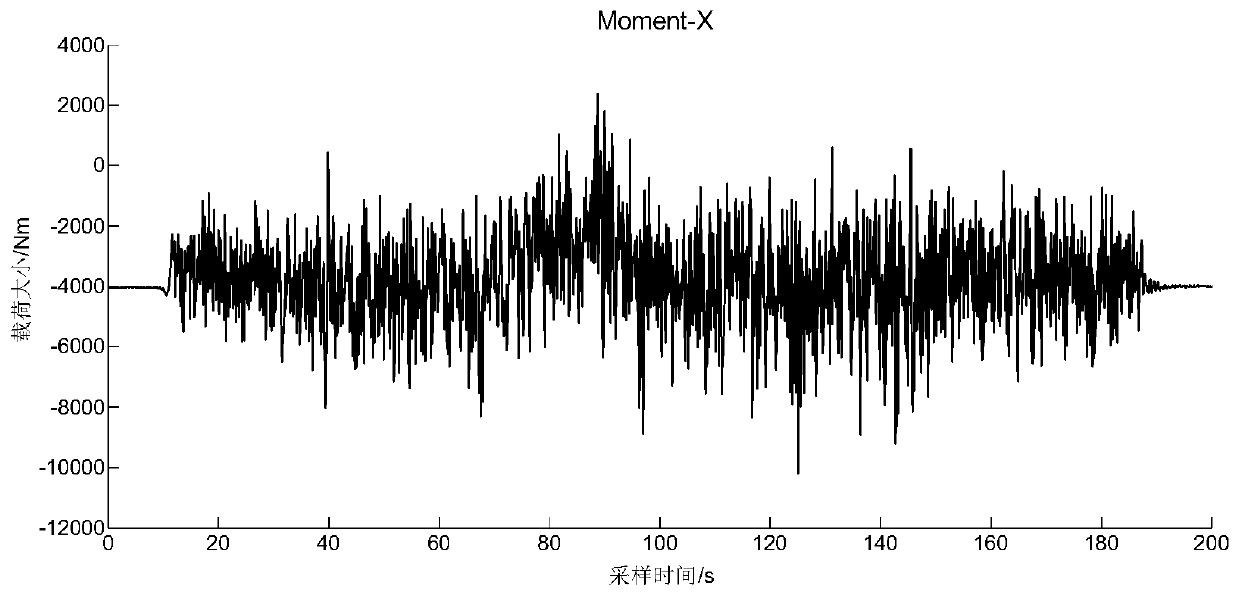

[0035] 1.1. The front wheel of a heavy-duty commercial vehicle is taken as the research component, and the random load is the six-component force data of the wheel measured on the proving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com