Multiply cable convenient pay-off unit

A pay-off device and convenient technology, which can be used in transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of time-consuming, labor-intensive, low-efficiency, and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

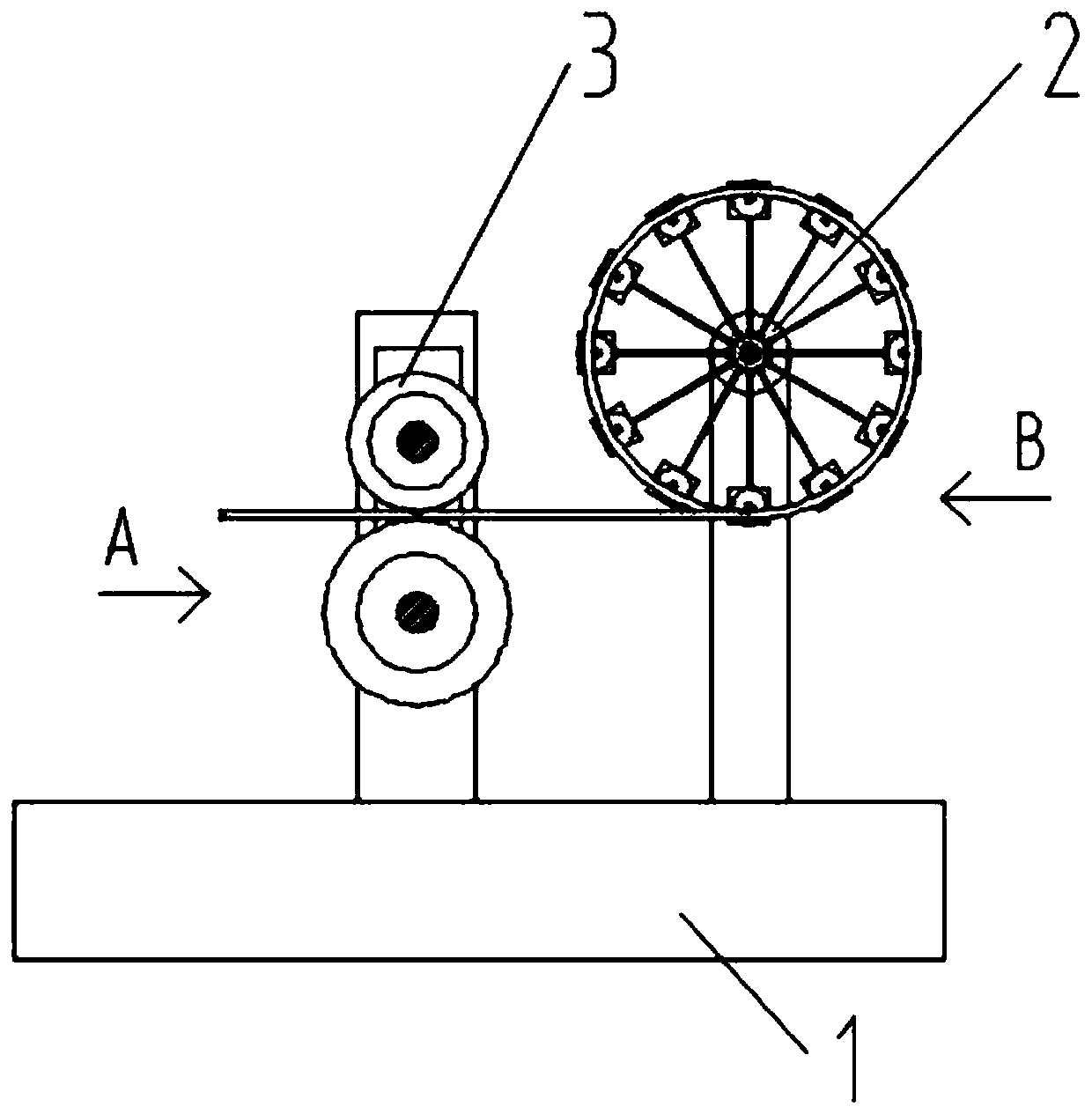

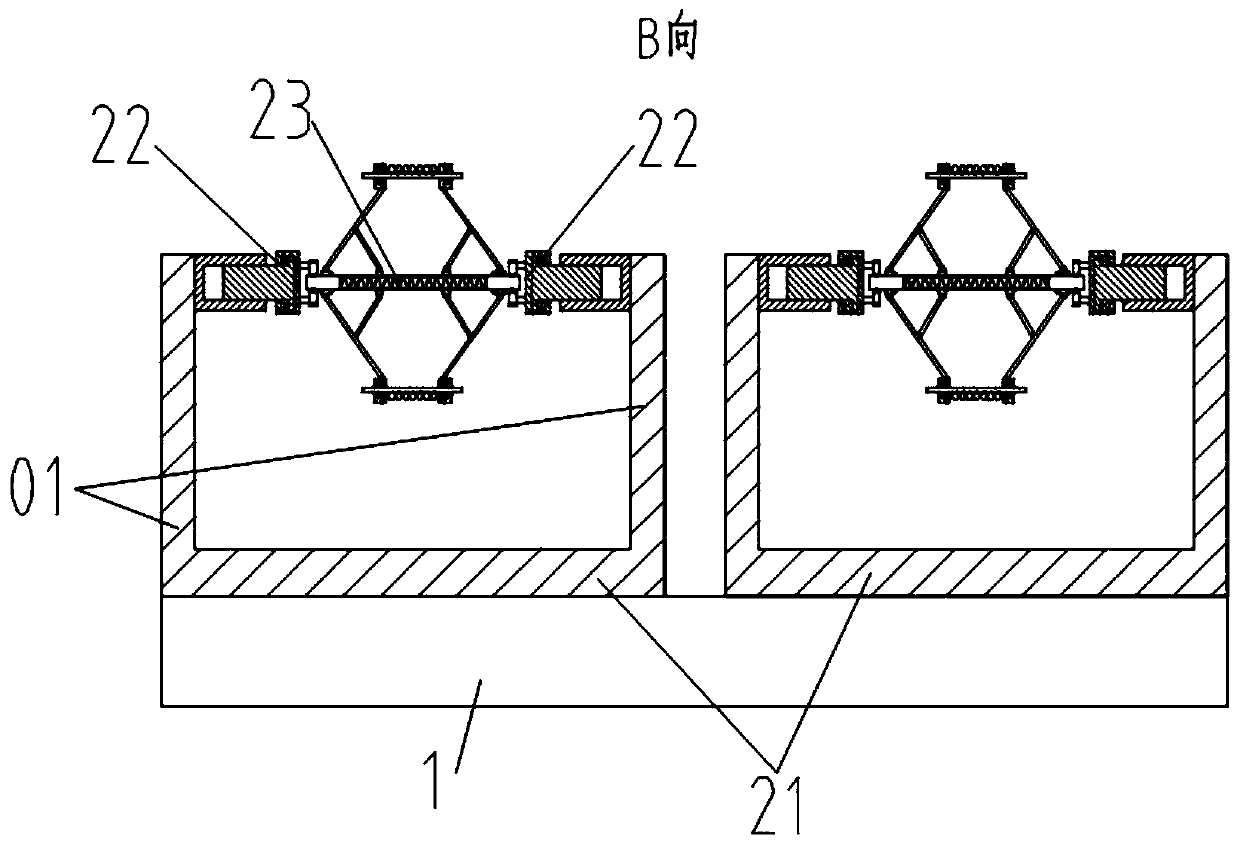

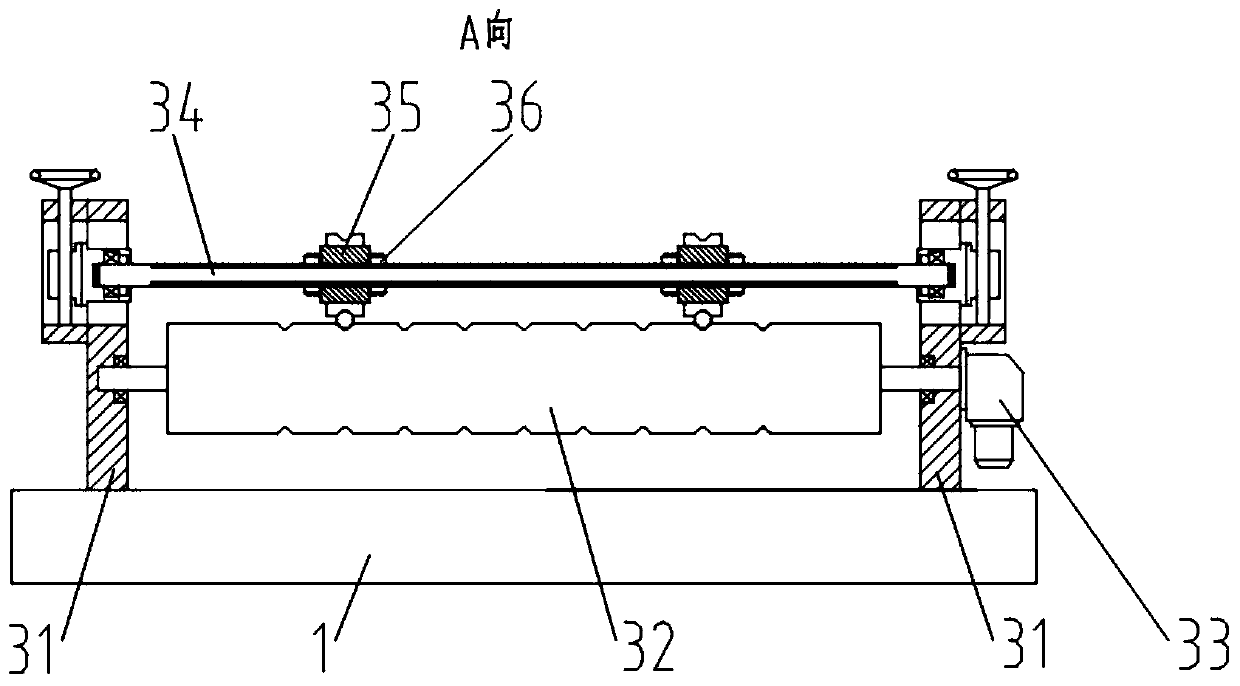

[0039] A convenient multi-cable pay-off device in this embodiment, such as Figure 1-Figure 3 As shown, it includes a base 1, which is characterized in that the base 1 is sequentially provided with a wire-feeding assembly 2 and a wire-feeding assembly 3 along the wire-releasing direction, and the wire-releasing assembly 2 is installed on the base 1 in sequence perpendicular to the wire-releasing direction. Several pay-off racks 21 on the top, the pay-off rack 21 includes two vertical columns 01 arranged symmetrically perpendicular to the wire-drawing direction, and the side near the top of the adjacent column 01 is respectively provided with a pay-off wheel seat 22, adjacent The variable diameter pay-off wheel 23 is rotated and installed between the pay-off wheel seats 22; the wire feed assembly 3 includes support frames 31 symmetrically arranged on both sides of the top of the base 1 along the line-release direction, and adjacent support frames 31 A power roller 32 is arrange...

Embodiment 2

[0046] This embodiment is further optimized on the basis of embodiment 1, such as Figure 4 As shown, the variable-diameter pay-off wheel 23 includes a variable-diameter axle 231, a movable sleeve 232, a fixed sleeve 233, a pole 234, a strut 235, a mounting plate 236, a rotating pin 237, and a locking member 238. A variable-diameter axle 231 is rotatably installed between the wheel bases 22, and a fixed sleeve 233 is fixed on both sides of the variable-diameter axle 231 symmetrically. The two sides of the fixed sleeve 233 are respectively hinged with one end of the strut 235 through the first hinge part, and the other end of the strut 235 is fixedly provided with a mounting plate 236; A movable sleeve 232 is arranged on the symmetrical sliding sleeve on the axial section between them. On the outer surface of the movable sleeve 232, a number of second hinge parts are arranged on the outer surface of the movable sleeve 232 along the circumferential direction corresponding to the...

Embodiment 3

[0053] This embodiment is further optimized on the basis of above-mentioned embodiment 1 or 2, such as Figure 5 As shown, a cross-column 02 is arranged between the tops of the adjacent columns 01 perpendicular to the direction of setting out the line, and the end of the cross-column 02 away from the column 01 is coaxially provided with a threaded mounting hole, and the threaded mounting hole is screwed. There is a connecting post 03 , the connecting end of which is protruding from the outside of the threaded mounting hole and is rotatably connected to one side of the pay-off reel seat 22 .

[0054] By rotating the connecting column 03, the depth of the connecting column 03 inserted into the threaded mounting hole on the horizontal column 02 can be adjusted. The column 03 is inserted into the threaded mounting hole synchronously, and the distance between the connecting columns 03 on both sides increases at this time, that is, the distance between the pay-off reel seats 22 on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com