Swirl generation plate and combustor system thereof

A technology of generating plate and swirling flow, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of carbon deposition, low combustion efficiency and power density of the heater, reduce the axial movement speed, and is conducive to fully Combustion, reducing the effect of working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

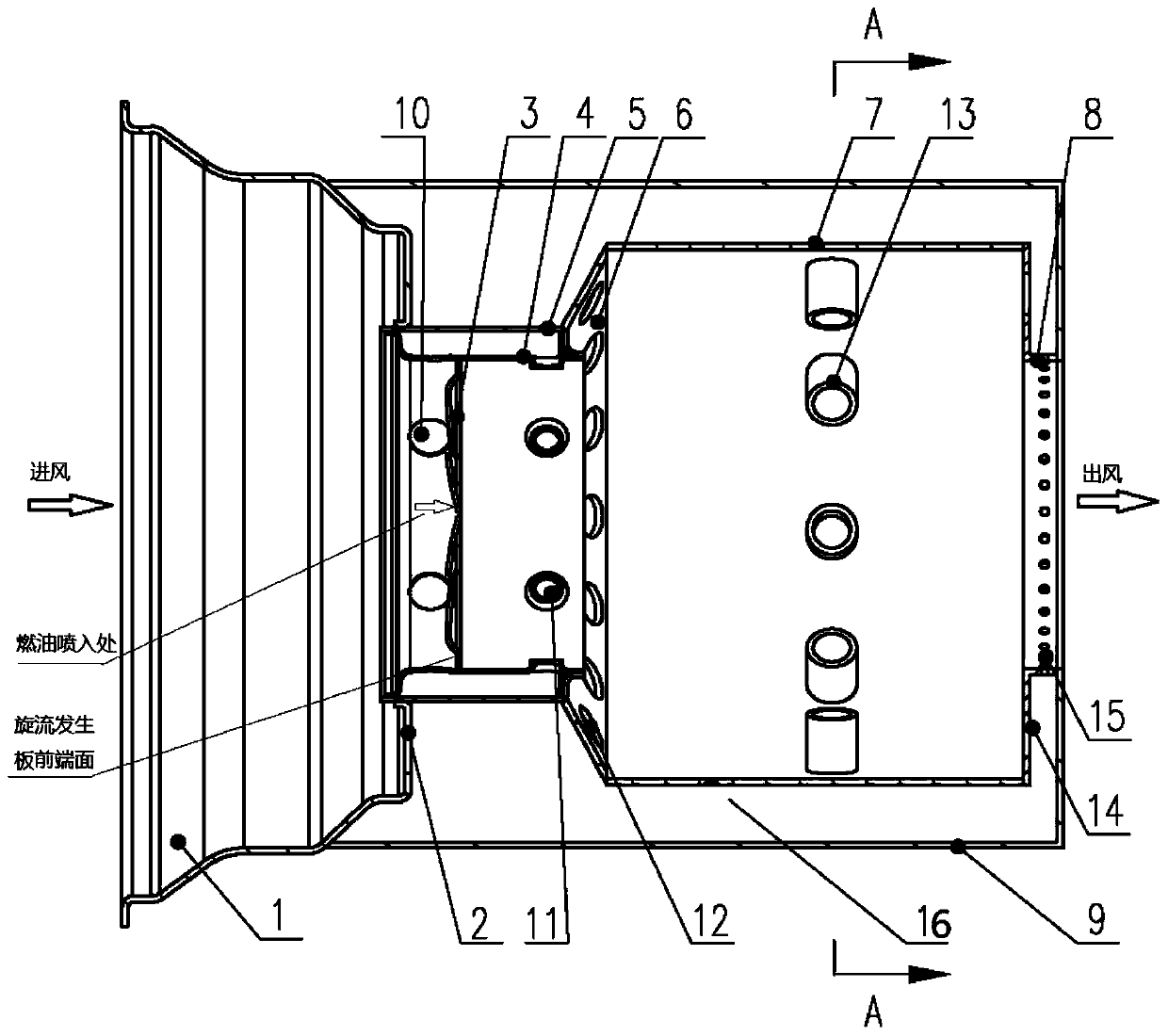

[0044] Such as figure 1 As shown, a premixed ignition and diffusion burner, the burner includes a burner outer cylinder, an air supply installation base, a premixed ignition chamber and a diffusion combustion chamber, the air supply installation base, a premixed ignition chamber and a diffusion chamber The burners are sequentially connected in series, and the premixed ignition chamber and the diffusion burner are arranged in the outer cylinder of the burner.

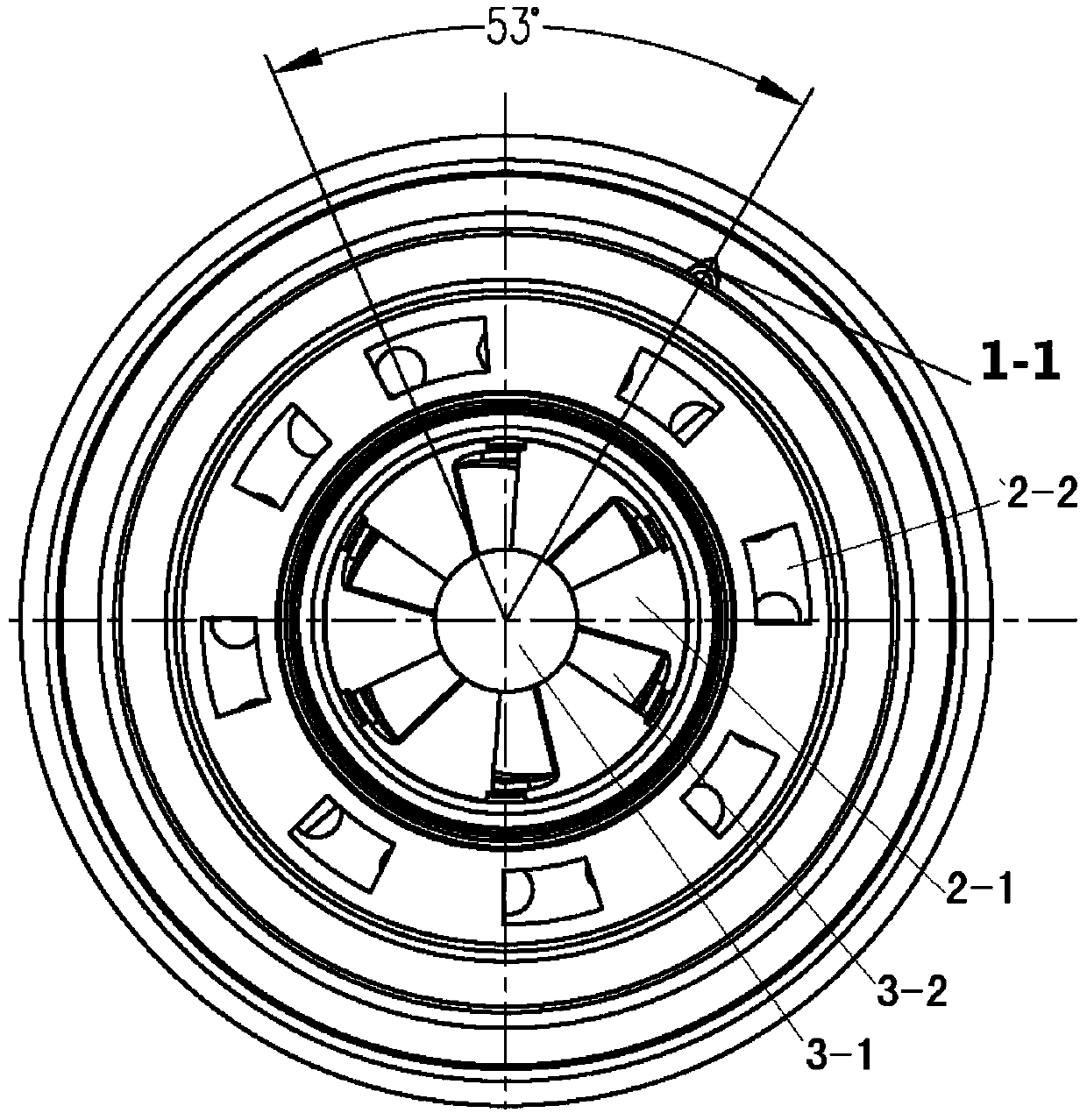

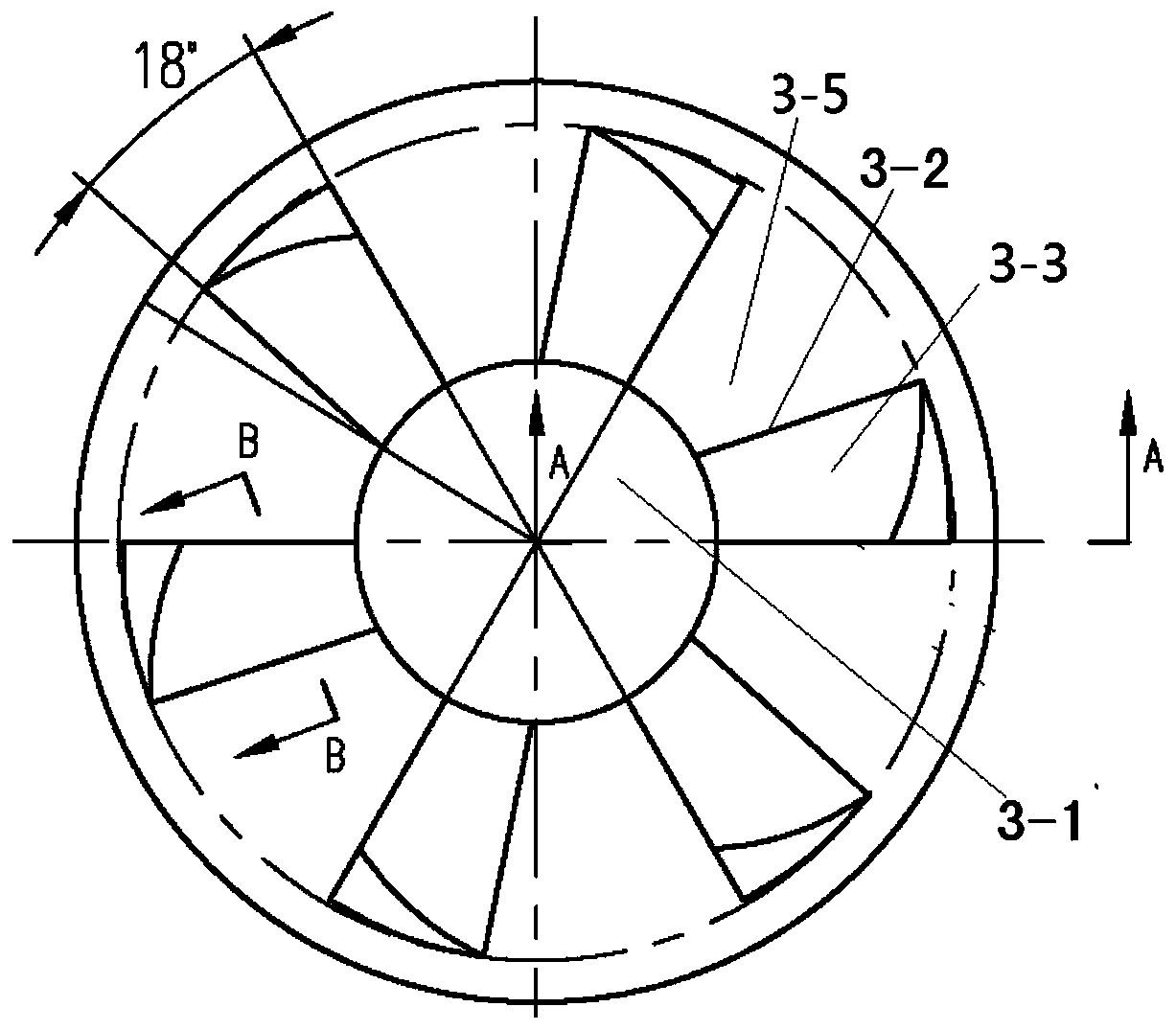

[0045] Preferably, the air supply installation base includes a mounting bracket 1 and a combustion air supply circular plate 2, the first end of the installation bracket 1 is open, and the second end is provided with a combustion air supply circular plate 2, and the combustion air supply circular plate 2 A central ventilation hole 2-1 is set in the center, and a circumferential vent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com