Heat preservation nail for tunnel in cold region

A technology for tunnels in cold regions and thermal insulation nails, which is applied to pins, connecting components, mechanical equipment, etc., can solve the problems of insufficient thermal insulation effect and failure to meet the requirements well, and achieve ideal fixing effect, good thermal insulation effect, and easy loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

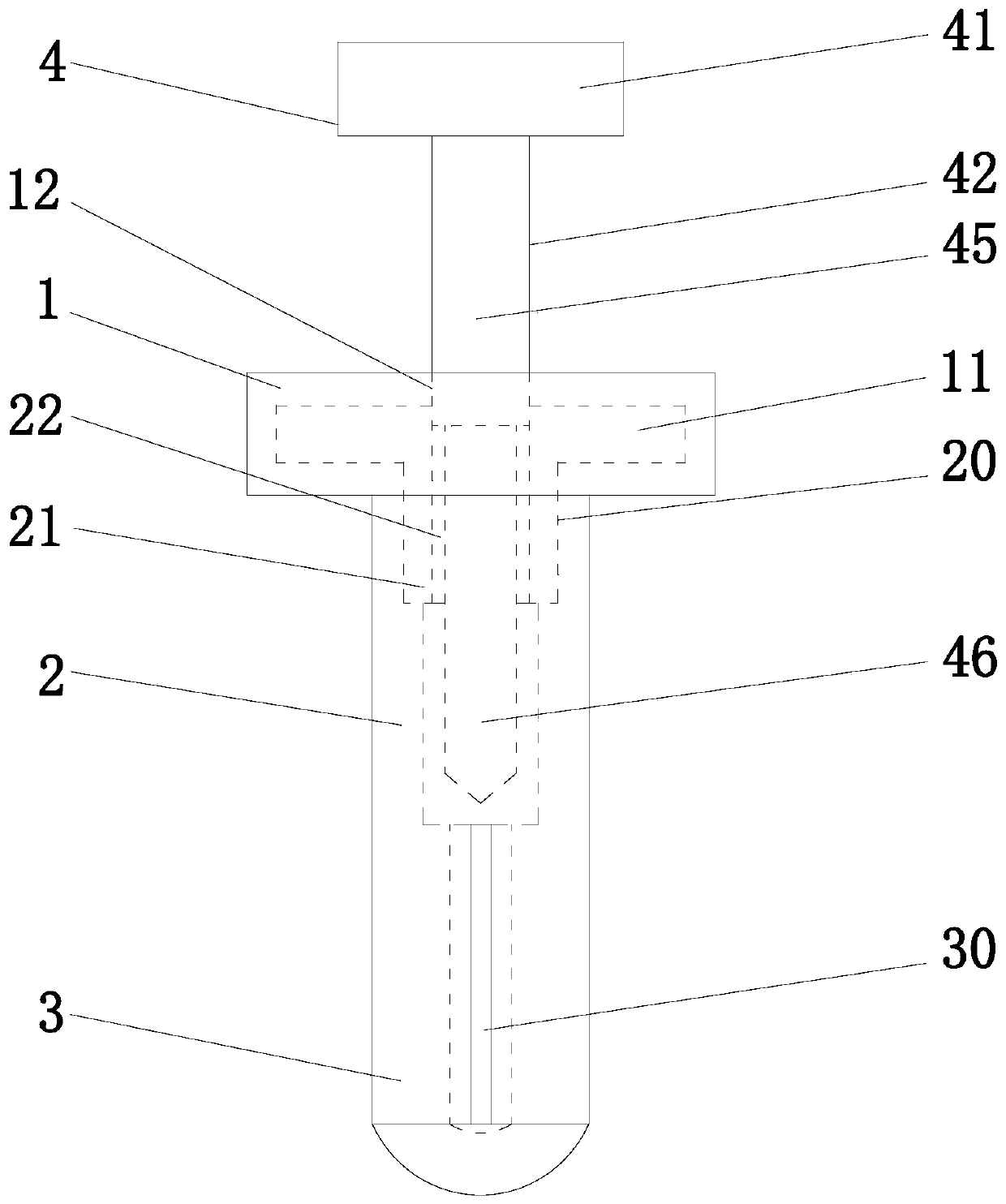

[0020] refer to figure 1 , a thermal insulation nail for tunnels in cold regions of the present invention, comprising a heat insulation plate 1, a reinforcing sleeve 21, a heat insulation sleeve 2, a heat insulation expansion sleeve 3, and a screw 4, and a heat insulation sleeve 2 is fixed at the bottom of the heat insulation plate 1 , a reinforcement sleeve 21 is embedded inside the heat insulation sleeve 2, a threaded hole 22 is provided on the reinforcement sleeve 21, a through hole compatible with the threaded hole 22 is provided on the heat insulation disk 1, the bottom of the heat insulation sleeve 2 A thermal insulation expansion sleeve 3 is connected, and the bottom of the thermal insulation expansion sleeve 3 is sealed. The thermal insulation expansion sleeve 3 is provided with several vertical separation grooves 30, and the separation grooves 30 run through the side wall of the thermal insulation expansion sleeve 3. The screw 4 is composed of a screw head 41 and a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com