A prefabricated thermal insulation board fixing component auxiliary installation device

A technology for fixing components and installation devices, which is applied in the directions of heat preservation, building components, building structures, etc., can solve the problems of beating deformation of connecting pipes, inconvenient transportation and carrying, damage to insulation boards, etc., avoiding bending, good clamping effect, and increasing The effect of a large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

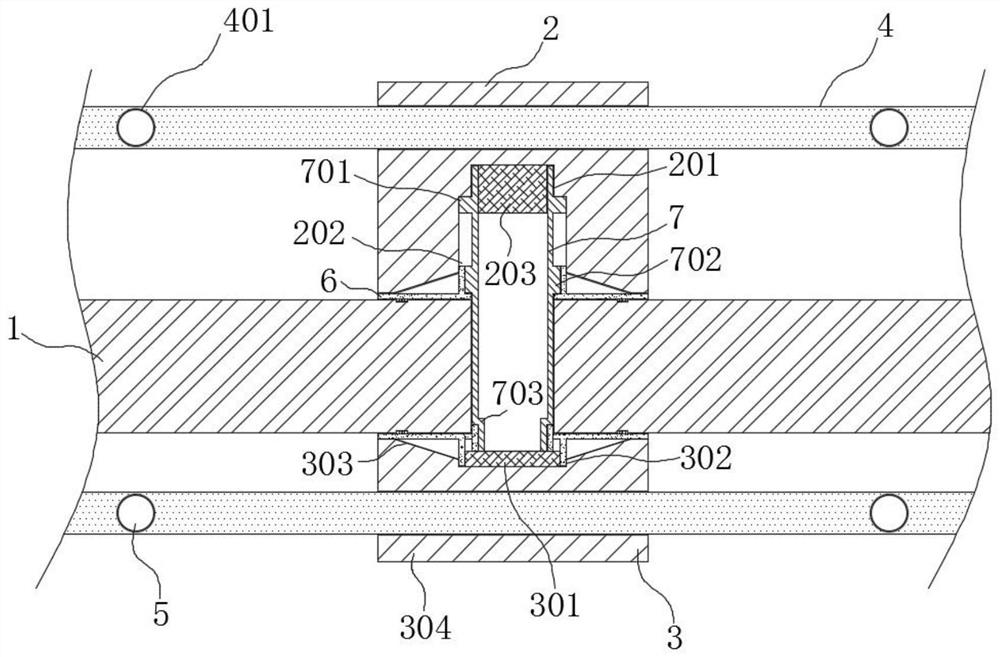

[0039] refer to Figure 1-5 , a prefabricated thermal insulation board fixing component auxiliary installation device, comprising a thermal insulation board 1, a plurality of equal-diameter mounting holes are evenly opened on the thermal insulation board 1, and a connecting pipe 7 is inserted in each mounting hole, and the connecting pipe 7 It includes a tube body 704, and the outer diameter of the tube body 704 is equal to the inner diameter of the installation hole. The tube body 704 is provided with a locking ring 701 and an abutting ring 702 from top to bottom, and the lower end of the tube body 704 is fixedly connected with a clamping tube 703 .

[0040] The connecting pipe 7 is provided with two clamping mechanisms 6 symmetrically, and the two clamping mechanisms 6 are symmetrically clamped on the upper and lower end surfaces of the insulation board 1. The clamping mechanism 6 includes a clamping plate 604, and the clamping plate 604 is provided with a through-hole. hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com