Turnover type get-on handrail device

A flip-up, armrest technology, which is applied to the special position of the vehicle, vehicle parts, transportation and packaging, etc., can solve the problems of hand wear, inconvenient hand gripping and extrusion of passengers, so as to achieve safe and convenient use and avoid passengers The effect of slipping the hand and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

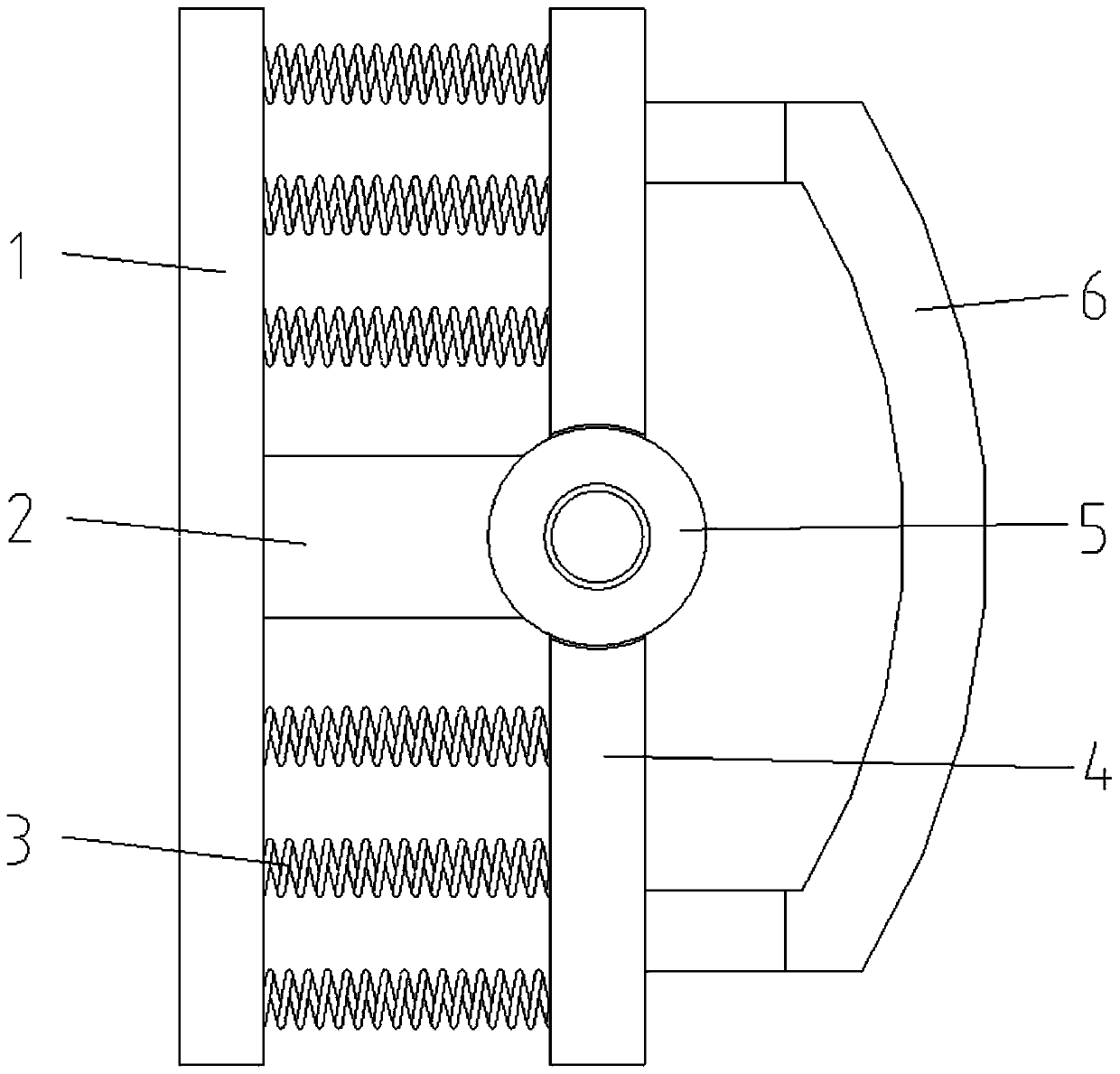

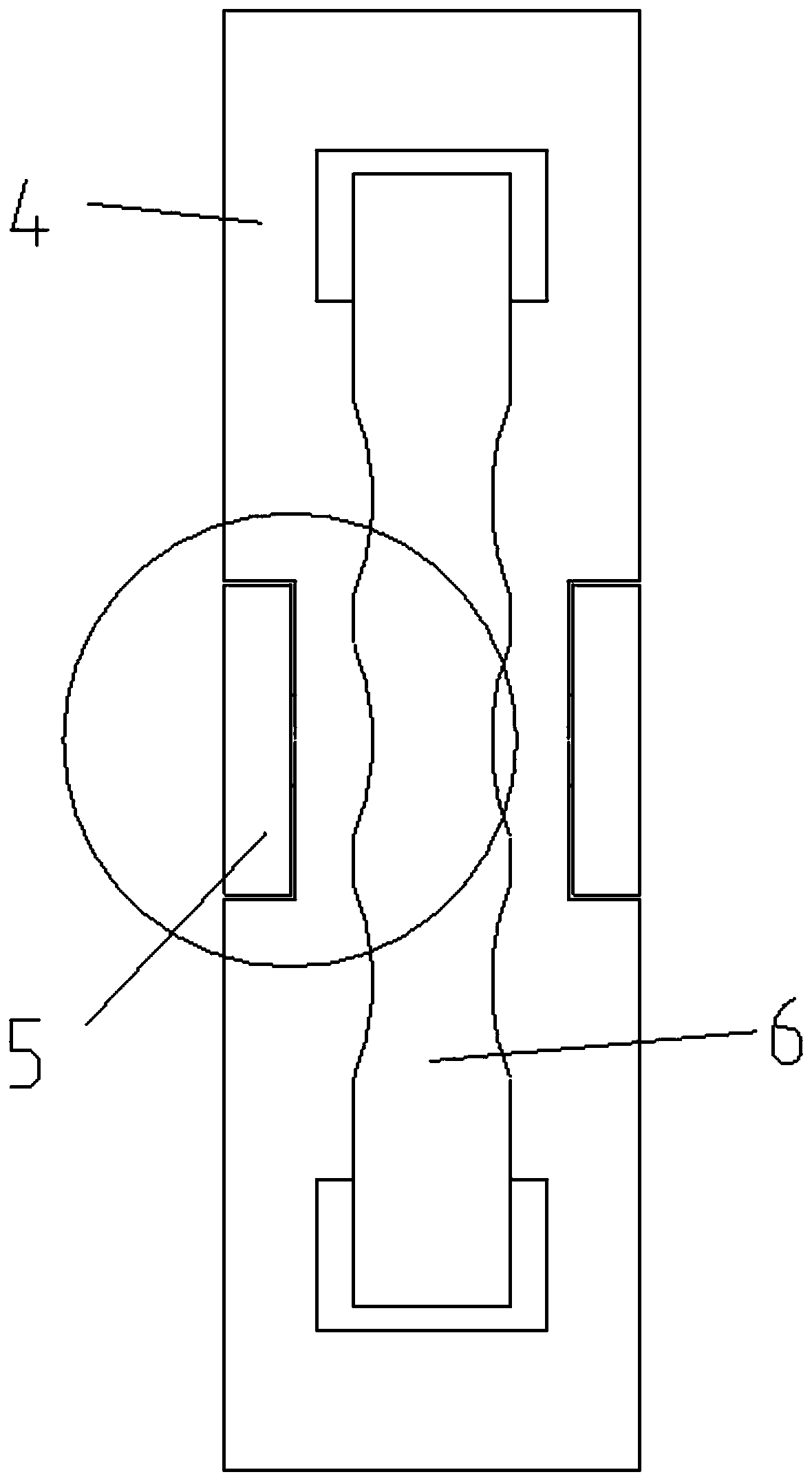

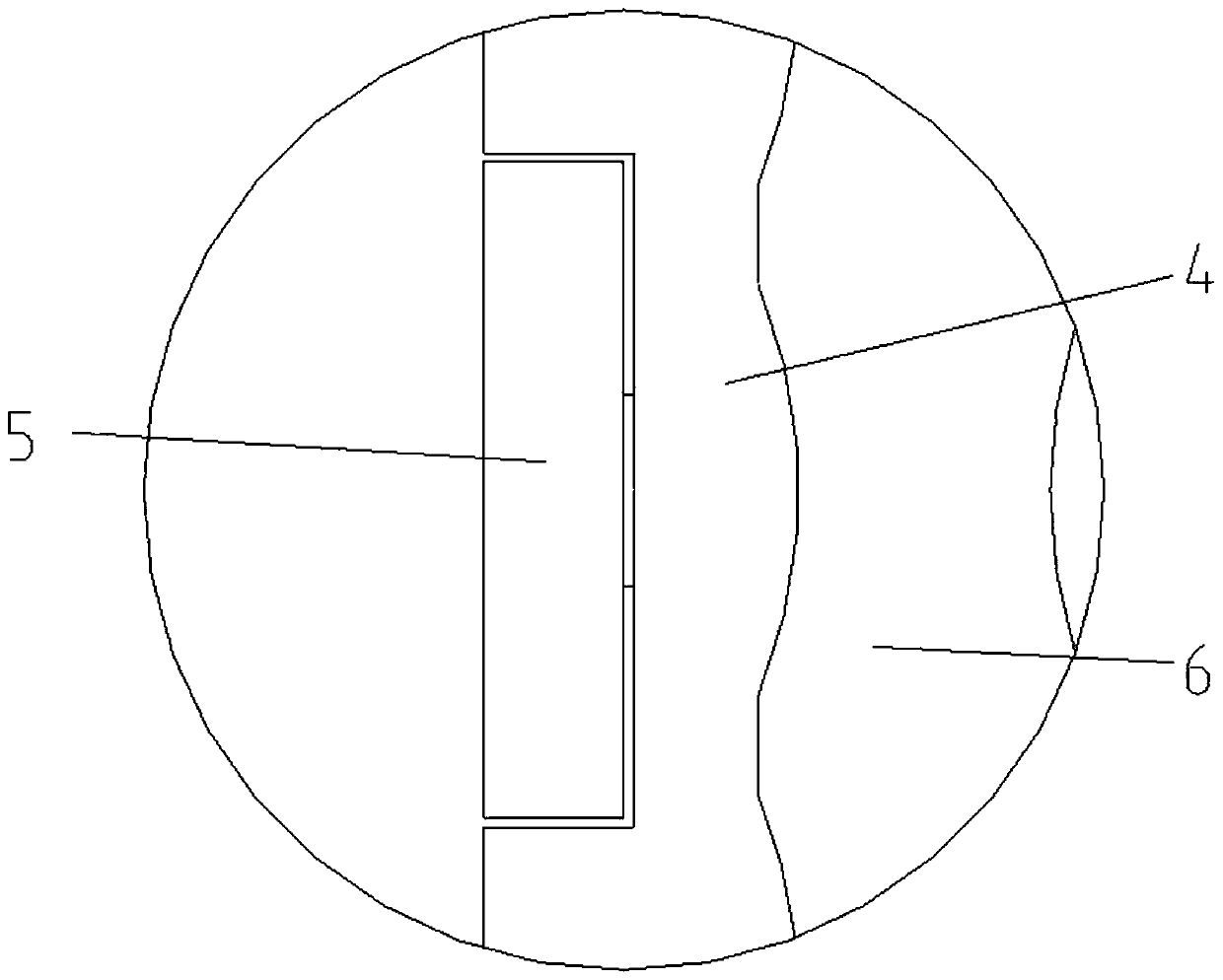

[0024] as attached figure 1 To attach image 3 Shown:

[0025] The present invention provides a turn-over handrail device for getting on a car, which includes a No. 1 base plate 1, a connecting plate 2, a strong spring 3, a No. 2 base plate 4, a rotating shaft fixing plate 5 and a handle 6; one side of the No. 1 base plate 1 is fixed symmetrically A total of two connecting plates 2 are connected; the other sides of the two connecting plates 2 are fixedly connected with a rotating shaft fixing plate 5; the inner sides of the two rotating shaft fixing plates 5 are movably connected with the second bottom plate 4 through the rotating shaft; A handle 6 is fixedly installed on the other side of the second bottom plate 4 .

[0026] Among them, a total of six rows of powerful springs 3 are fixedly installed symmetrically up and down between the No. 1 base plate 1 and the No. 2 base plate 4, and the strong springs 3 will push the No. 2 base plate 4 to make the No. 1 base plate 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com